Lupine Publishers| Journal of Civil Engineering and its Architecture

Abstract

This paper presents the results of an extensive research that evaluated the laboratory characteristics of hot and warm mix asphalt mixtures manufactured with 100% virgin materials and with 15 and 35% recycled asphalt pavement. The overall objective of the study was to evaluate the engineering properties and performance characteristics of the mixtures while the specific objective was to assess the ability of the warm mix additives in allowing the use of higher content of recycled asphalt pavement without changing the performance grade of the virgin binder.

All mixtures were designed with the Marshall mix design method. The engineering properties consisted of the dynamic modulus master curve while the performance characteristics covered the mixtures resistances to moisture damage, rutting, thermal and fatigue cracking. The analysis of the data led to the following conclusions: warm mix additives were effective in moderating the increase in the engineering property of the mixtures containing 15 and 35% recycled asphalt pavement as compared to the hot mixtures without significantly reducing their resistance to rutting and thermal cracking, however, the warm mix additives were not capable of maintaining good resistance to fatigue cracking, therefore, the idea of using warm mix additives to allow higher recycled pavement in the asphalt mix is not supported by the measured resistance of the mixture to fatigue cracking.

Keywords: Warm mix; Recycled asphalt pavement; Marshall mix design; Dynamic modulus; Moisture damage; Rutting; Thermal and fatigue cracking

Introduction

Production of asphalt mixtures have always been challenging in terms of environmental friendliness and workers’ health. Various efforts are taken to address these concerns in paving industry. One of the approaches taken is to maximize the use of Recycled Asphalt Pavement (RAP) in asphalt mixtures, which helps in minimizing the use of natural asphalt binder and aggregates. Another approach is replacing Hot Mix Asphalt (HMA) with Warm Mix Asphalt (WMA) technologies, that lowers the production and laying temperatures of asphalt mixtures.

The majority of the states in US started using WMA and over 20WMA technologies are available in the US market. Boriak et al. conducted a laboratory study to examine the effect of 20 and 40% RAP contents on asphalt mixtures when the optimum asphalt binder is increased by 0.5% [1]. Evaluation of the mixtures were based on dynamic modulus, rutting resistance, and fatigue resistance of the asphalt concrete (AC) mixtures. An increase of 0.5% in the optimum asphalt binder content in mixtures with 0% and 20% RAP improved rutting and fatigue resistance of the mixtures while maintaining similar dynamic modulus. However, a significant drop in rutting resistance with no change in fatigue resistance was observed in the case of mixtures with 40% RAP.

Hajj et al. conducted a laboratory evaluation for the use of RAP in HMA mixtures [2]. Rutting, fatigue and thermal cracking, and moisture resistance characteristics of the HMA mixtures with 15 and 30% of RAP contents from three different sources were included in the evaluation. For polymer-modified mixtures, the study concluded that mixtures with 15 or 30% RAP will have an acceptable moisture resistance, equivalent rutting resistance, but reduced fatigue cracking resistance regardless of the sources of RAP.

Loria et al. evaluated asphalt mixtures with high RAP content in terms of resistance to moisture damage and thermal cracking [3]. Laboratory and field mixtures were compared based on their properties and performance. The research concluded that HMA mixtures with 50% RAP have acceptable resistance to thermal cracking and moisture damage. Measured Performance Grade (PG) temperatures from the recovered asphalt binder and the estimated critical temperatures from blending charts showed acceptable correlations. Overall, the study concluded that the resistance to moisture damage and thermal cracking of field produced asphalt mixtures can be evaluated from laboratory produced mixtures.

Objective and Scope

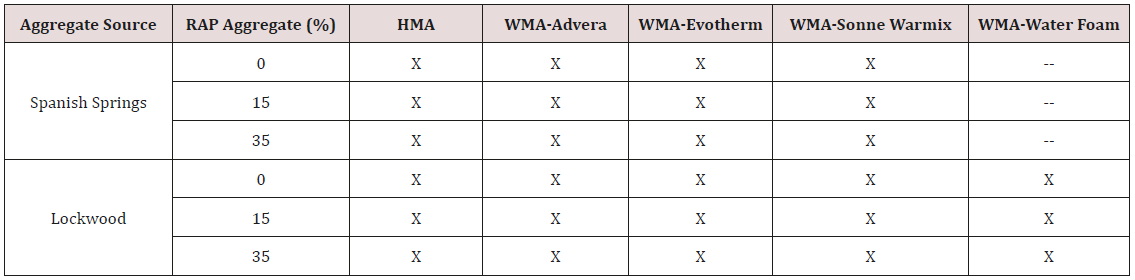

The objective of this study was to conduct comparative evaluations of mixtures that include various WMA technologies and different percentages of RAP. The research evaluated HMA and WMA mixtures from the “Spanish Springs” aggregate source, with three WMA technologies: Advera, Evotherm 3G, and Sonnewarmix and the HMA and WMA mixtures from the “Lockwood” aggregate source with the same three WMA technologies in addition to the Water Foam technology. Both aggregate sources are located in the northern part of the state of Nevada, USA and commonly used in the production of asphalt mixtures. All mixtures used the PG64-28NV polymer modified asphalt binder. Table 1 presents the summary of the experimental plan.

Materials Characterization

Aggregates

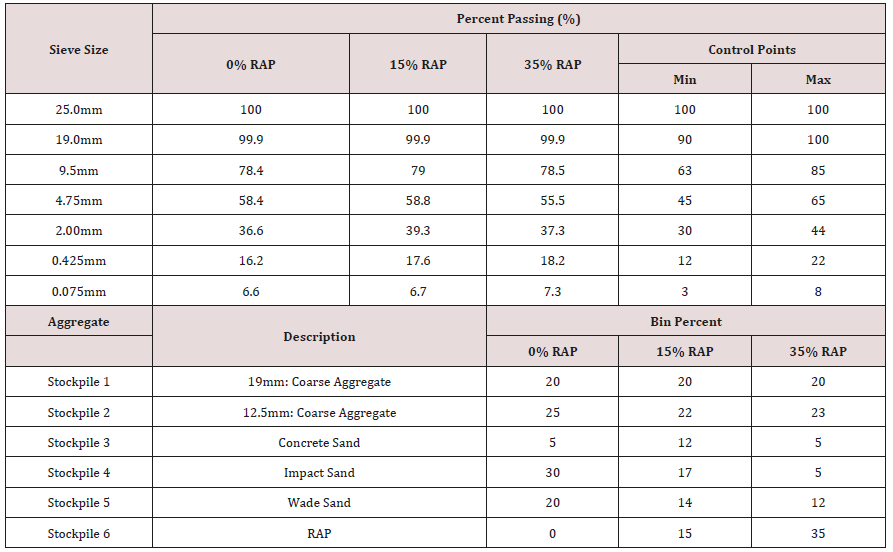

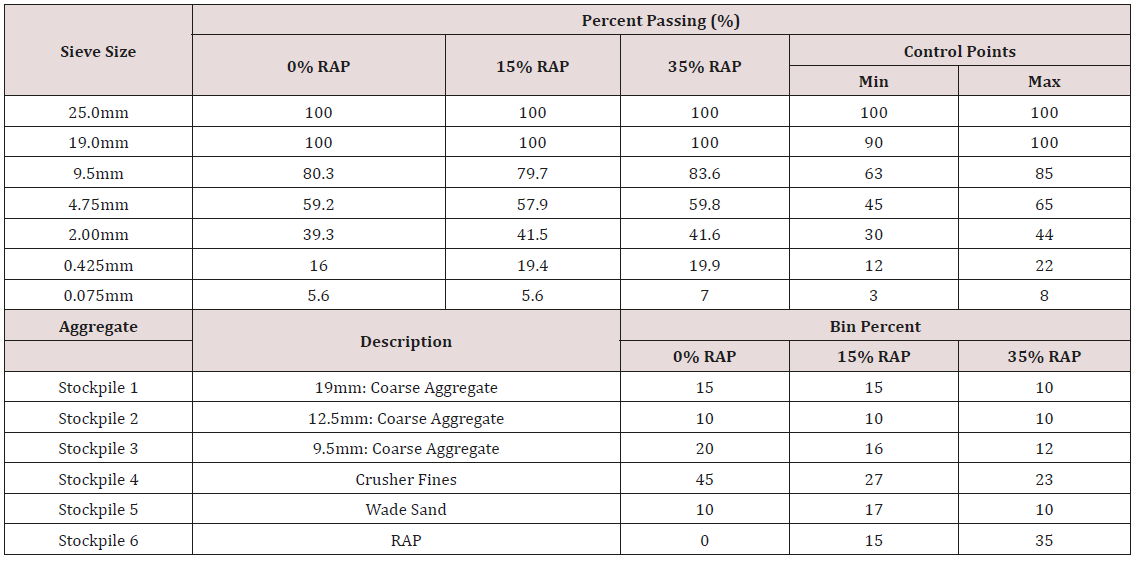

Aggregates used in this study were obtained from Spanish Springs and Lockwood sources. Five stockpiles of virgin aggregates and a RAP stockpile were used from each of the two aggregate sources. Aggregates blends were prepared from the aggregate stockpiles of each source that meet the Regional Transportation Commission (RTC) aggregate gradation specifications. Tables 2 & 3 present the bin percentages from the stockpiles and final gradation of the prepared blends. Specific gravity and relevant aggregate properties of various blends prepared are presented in the mix design summary. Difference in specific gravities among the stockpiles were less than 0.2, therefore, corrections of blend gradations were not required. Specific gravities of Spanish Springs aggregates were slightly higher than Lockwood aggregates. In addition, Lockwood aggregates had higher absorption compared to Spanish Springs aggregates. It should be noted that the aggregates were conditioned with hydrated lime for 48 hours prior to mixing process following the procedure specified in RTC specifications.

Asphalt Binder

The asphalt binder used for the study graded as PG64-28NV, which is a polymer modified asphalt binder. Performance grade (PG) of the asphalt binder was verified in the University laboratory following AASTHO M320 standard procedure. The actual grades for the asphalt binder were determined as 68.6 and -32.5 for the high and low temperatures, respectively. Range for mixing and compaction temperatures were provided by the supplier; 160 °C to 165 °C for mixing and 150 °C to 155 °C for compaction.

RAP Materials

RAP materials were collected from the Spanish Springs and Lockwood aggregate sources. Average asphalt binder contents for the Spanish Springs and Lockwood RAP were determined as 4.4% and 5.5% by dry weight of aggregate, respectively. Actual PGs for the Spanish Springs RAP binder were determined as PG87.9-27.8 whereas for the Lockwood RAP binder as PG85.3-26.3. Therefore, the standard PG of the RAP asphalt binders for both sources were identified as PG82-16. RAP aggregates were recovered and evaluated for gradation and specific gravity. The Nominal maximum size of both RAP aggregates was identified as 9.5mm. Absorption of the Lockwood RAP aggregates is higher than the absorption of the Spanish Springs RAP aggregates which was also the case for virgin aggregates.

Mix Designs

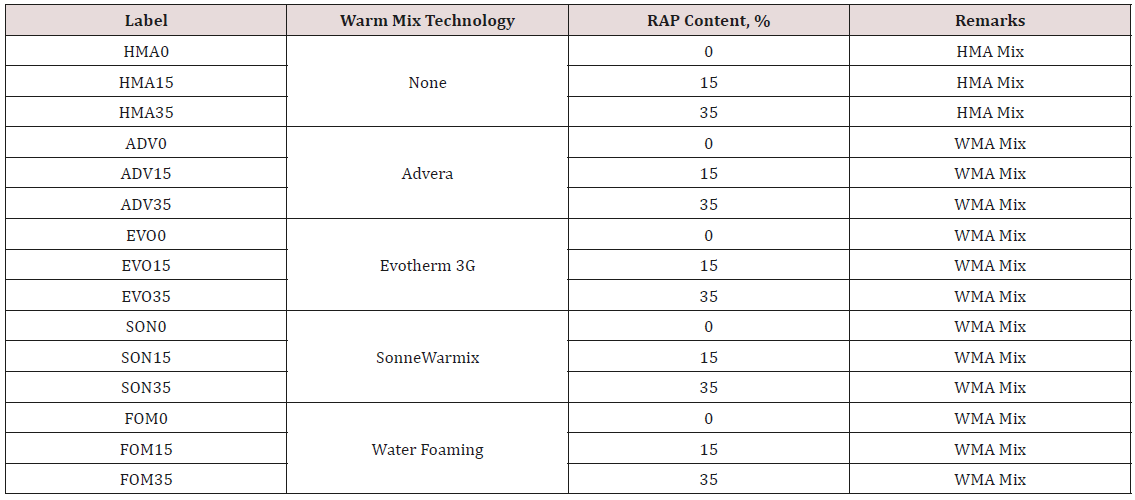

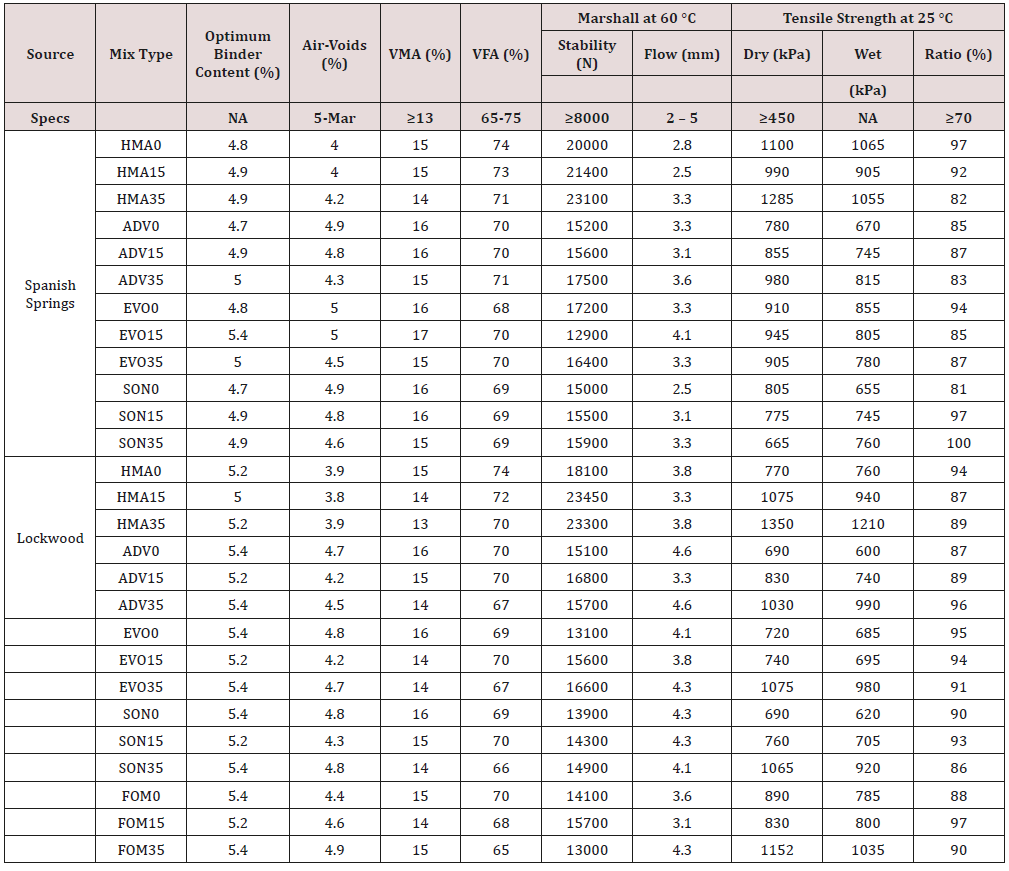

Nomenclature for the various mixtures were established according to the modification type and RAP aggregate percentage. For instance, HMAO, ADV15 and EVO35 represent HMA control mixture with no RAP, mixture with advera modification and 15 percent RAP, and mixture with evotherm modification and 35 percent RAP. Summary of the mixtures nomenclatures is presented in Table 4. Marshall Mix designs were conducted following the standard procedures established in the Asphalt Institute Manual “MS-2”, and criteria meeting the RTC specifications which are presented in Table 5. Mixing and compaction temperatures for the control mixtures were considered as provided by the supplier. However, for the WMA mixtures, mixing and compaction temperatures were selected at 135 °C and 120 °C, respectively, which are also the recommendation provided by the WMA technology suppliers. Table 5 summarizes the mix design results for both aggregate sources, three level of RAP contents, and various WMA technologies. It can be observed that the optimum binder content (OBC) at a specified air voids are higher for the Lockwood aggregate which is explained by its high absorption capacity compared to Spanish Springs Aggregate. All mixtures satisfy the requirement criteria for VMA, VFA, Marshall Stability, and Marshall Flow.

For the Spanish Springs mixtures, the OBC for WMA mixtures with RAP were greater or similar to the HMA control mixtures. WMA mixtures were observed to have higher percentage of air voids at OBC than HMA control mixtures. It was also observed that, except for HMA control mixtures, air voids at OBC decreased with the increase in RAP content. Marshall Stability was observed to be increasing with the increment in RAP content. Also, WMA mixtures exhibited lower Marshall Stabilities compared to HMA mixtures. HMA mixtures have shown higher Marshall Flow than the WMA mixtures. However, a clear trend was not observed for the Marshall Flow with the percentage of RAP.

In the case of Lockwood mixtures, air voids at OBC for the HMA mixtures were observed lower than WMA mixtures. WMA mixtures had OBC higher than HMA mixtures by 0.2%, at all levels of RAP content. It was interesting to observe that the OBC for the 0 and 35% of RAP were similar, but the mixtures with 15% RAP had lower OBC. Trend for the Marshall Stability was similar to Spanish Spring mixtures. However, it was interesting to observe that the flow for mixtures with 15% RAP was lower than for the 0 and 35% RAP mixtures.

Read More About Lupine Publishers Journal of Civil Engineering and its Architecture Please Click on Below Link: https://lupinepublishers-civilengineering.blogspot.com/

No comments:

Post a Comment

Note: only a member of this blog may post a comment.