Abstract

The Hindu Kush Himalaya (HKH) region has significant implications for

the agro based economies of eight adjoining countries,

because of their large dependence on irrigation water originating in the

HKH region. However, the HKH region is extremely

vulnerable to climate change impacts, which is evident through frequent

floods, droughts and retreating glaciers, thus leaving

negative consequences for agriculture and livelihood. It is also evident

that the traditional farming methods are no longer sustainable

to cope with the changing climatic conditions for sustainable production

in hill ecology. Therefore, innovative farming technique

and irrigation technologies needs to be adopted for mitigating climate

change impacts on agriculture and for ensuring food security.

Although some pioneer work has been done in developing and promoting

improved farming methods and irrigation techniques, but

these improvements were mainly focused in major leveled irrigated areas

lying downstream of HKH region. Thus, investment on

promoting site specific climate resilient practices in hill ecology of

HKH was largely overlooked. Addressing these issues, this study

is focused on assessment of agricultural production system of Pakistan,

as a case example by having 51% area falling in HKH region

and reviewed few promising interventions/technologies successfully

adopted in downstream irrigated areas that may be equally

beneficial for the hill ecology of HKH region. Anecdotal evidence

indicates that promotion of these interventions will improve

community resilience to climate change and may lead to increased

agricultural production and better livelihood for hill ecology of

HKH region. This may also improve sustainable irrigation water supply

for the irrigated areas downstream.

Introduction

The total area of Hindu Kush Himalaya (HKH) region is ~ 3.44

million sq. km spread over eight countries of Asia. The 51% area

of Pakistan (~0.4 million sq. km) falls in HKH region, which form

around 12% part of the whole HKH region [1]. Pakistan is home to

one quarter (~19%) of the total population (~211 million people)

of HKH region with an average population density of 97 persons

per sq. km. The second (K2) and ninth (Nanga Parbath) highest

peaks of HKH region fall in Pakistan. The agro based economy of

HKH region in Pakistan is heavily dependent on the production of

vegetables, crops and fruits. Current climate change trends and lack

of adequate integrated water resource management strategies are

causing huge losses to the country due to frequent droughts and

floods [2]. Therefore, traditional farming techniques prevalent in

Pakistan are no longer capable to keep up with the rapid climate

change variability in the HKH region [3,4] and its downstream

basins.

The Indus Basin of Pakistan is comprised of one of the largest

contiguous canal irrigation systems in the world that lies at the

downstream of HKH, thus prone to frequent climatic disasters [5].

For instance, the recent 2010 floods, originated in HKH region,

drowned around one fifth of Pakistan, affected ~20 million people

and caused more than US $43 billion impact on the country’s

economy [6]. Irrigated agriculture produces around 90% of

crop production in Pakistan and contributes more than 21% in

the country’s GDP. Moreover, production in Pakistan has global

implications, thus may impact on global food security. For instance,

Pakistan produces wheat crop greater than the whole Africa and

nearly equal to South America. Therefore, agriculture needs to

be more wisely managed and traditional farming and irrigation

methods needs to be modified according to the changing climatic

conditions. This paper reviews some of the salient features of

agriculture in Pakistan, its vulnerability to climate change and few

promising irrigation technologies capable of improving farming

system resilience to climate change.

Salient Features of Pakistan’s Agriculture and their

Vulnerability to Climate Change

Land use in Pakistan

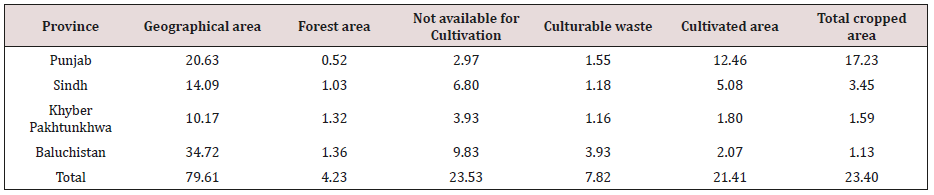

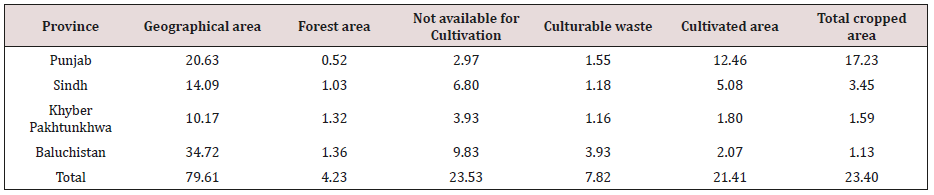

The province wise land use is presented in Table 1. The total

area of Pakistan is 79.61 million hectares (mha) with 23.40 mha

cropped area. The current cultivated area is concentrated in Punjab

province with 12.46 mha, which is ~50 % of the total cropped

area of Pakistan followed by Sindh Province at ~8 % of country’s

cropped area. However, there is 7.82 mha culturable waste area

that is largely concentrated in least developed provinces of Khyber

Pakhtunkhwa (KP) and Baluchistan, which can be brought under

cultivation to enhance food security. The province wise culturable

waste areas are 12%, 23%, 64% and 190% of current cultivated

lands in Punjab, Sindh, KP and Baluchistan respectively. Therefore,

the agro based economies of KP and Baluchistan has greater

potential for improvement by cultivating their culturable waste

lands.

Table 1: Land use in Pakistan.

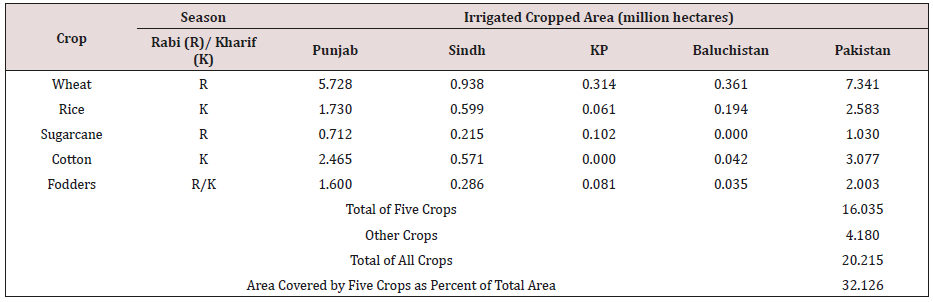

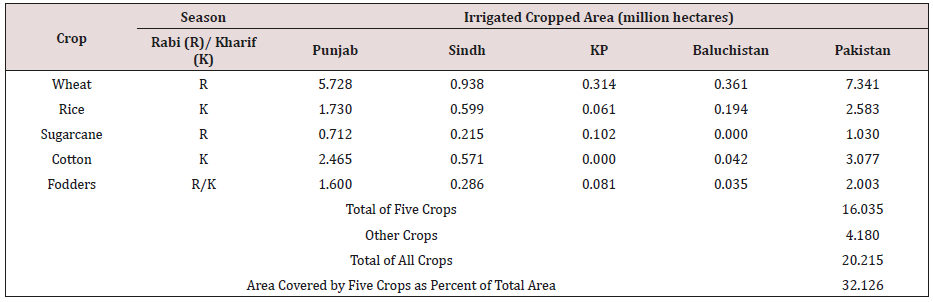

The irrigated cropped area in Pakistan is around 18.84 mha

(Table 2) according to Agriculture Statistics of Pakistan 2006-07.

This includes: wheat 7.34 mha (36.3 % of total); rice 2.58 mha

(12.8 % of total); cotton 3.01 mha (15.2 % of total); sugarcane

1.03 mha (5.1 % of total); and fodders 2.00 mha (9.9 % of total).

These five crops cover 16.03 mha of total irrigated area in Pakistan,

which is 79.32% of the total irrigated area. Therefore, improving

water productivity of these five major crops would have major

impacts on productivity of irrigated agriculture in Pakistan. Other

crops cover 4.17 mha; which constitute around 21.68 % of total

irrigated area in Pakistan. The climate change induced floods and

droughts significantly impact on crop production, especially during

Kharif (summer) season, from both irrigated and rain-fed areas

of Pakistan. The current land use methods tend to exacerbate the

soil and water degradation and reduce land productivity potential.

Similarly damage to standing crops due to lodging caused by heavy

winds, water logging and salinity and frequent water stresses at

crop critical growth stages causes production losses. Therefore, the

traditional farming techniques need to be modified to control crop

damage due to climate change induced threats, which is essential

for sustainable agriculture in the country.

Table 2: Irrigated cropped area of major crops in Pakistan.

Temporal Water Availability During Rabi and Kharif

Seasons In Pakistan

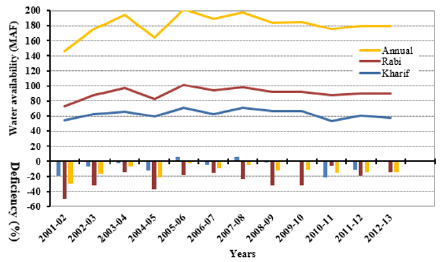

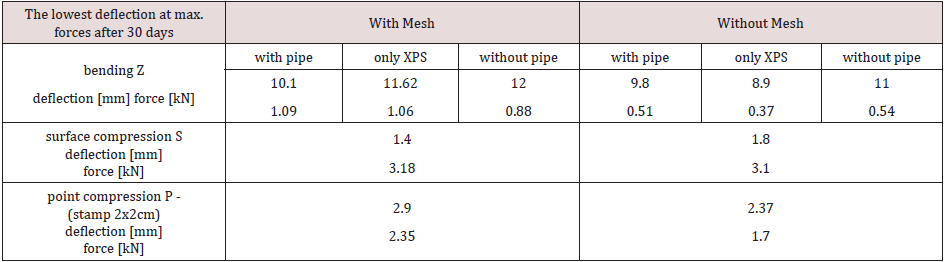

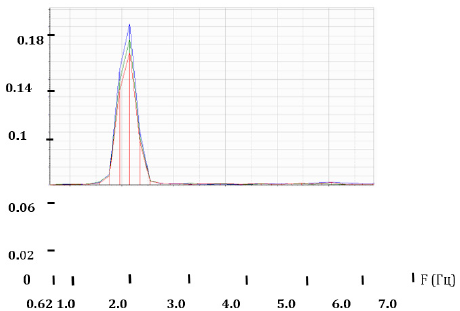

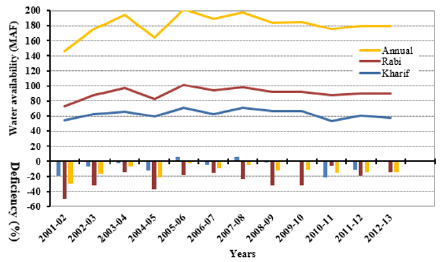

Temporal surface water availability and deficiency during rabi

(winter) and kharif (summer) seasons in Pakistan is shown in

Figure 1. Temporal changes indicated up to 23% increase and down

to 16% decrease in total annual available surface water since 2001

until 2007. However, the variability in total annual available surface

water diminished below 5% since 2009 onward. Interestingly a

major flood occurred during 2010, but data show insignificant

impact on the total water availability (Figure 1). Thus, climate

change cannot be judged from the total water availability. However,

the frequency, intensity and distribution of rainfall are important

parameters to be considered. Similarly, the average deficiency

remained around 6.4% during Kharif (summer season) and around

24% during Rabi (winter season) with an average annual water

deficiency of around 13% during the last twelve years.

Figure 1: Temporal surface water availability and deficiency during rabi (winter) and kharif (summer) seasons in Pakistan.

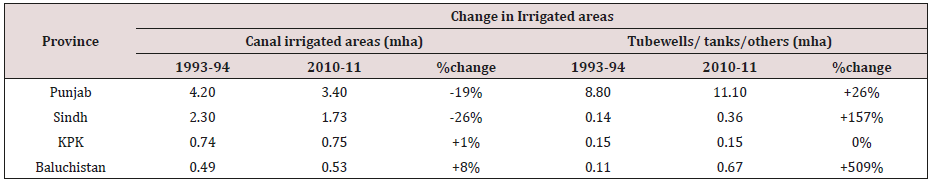

Increased Use of Groundwater in Pakistan

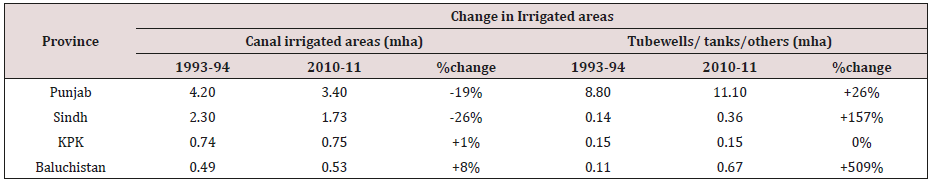

Canal water fluctuation and unreliability due to climate change

has increased farming community dependence on groundwater

during the last decade. The changing trend of water availability is

presented in Table 3. The statistics of canal and tube well irrigated

area in provinces from 1993-94 to 2010-2011 (Table 3) indicate a

decrease of 19% and 26 % in canal irrigated areas and an increase

of 26 % and 157% in tube well irrigated areas in Punjab and Sindh

provinces respectively. The overall tendency from 1993-94 to 2010-

11 indicated a decrease of 17.5 % in the canal irrigated areas and

an increase of 33.5 % in groundwater irrigated areas in Pakistan.

The overexploitation of groundwater is coupled with saline water

up-coning and disposing of deep brackish groundwater into the soil

surface thus causing fertile lands barren in Pakistan. It is therefore

essential to reduce groundwater usage by utilizing surface water

more efficiently for fulfilling irrigation demands of larger areas.

Thus, the traditional irrigation methods need to be modified to

more efficient methods to reduce groundwater usage.

Table 3: Temporal change in irrigated area under surface and groundwater in Pakistan.

Climate Resilient Interventions for Improving

Food Security in HKH Region

The existing land use, crops, water availability and usage

statistics clearly indicate that the traditional farming techniques

are not capable to cope with the climate change induced risks. It is

therefore essential to adopt suitable climate change risks mitigation

interventions for improving food security in HKH region. Few of

these interventions/technologies successfully adopted in irrigated

leveled lands downstream of HKH are summarized below:

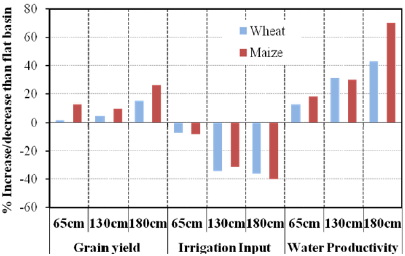

Furrow Bed (Raised Bed) Irrigation Systems

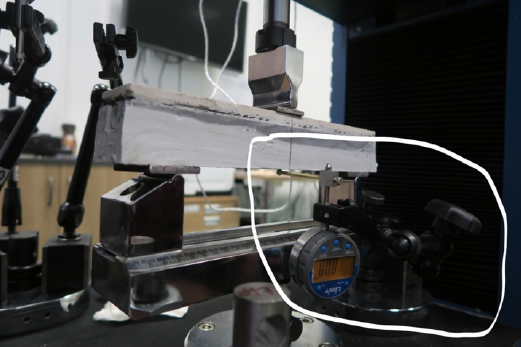

Furrow bed irrigation system is one of the commonly used

form of surface irrigation throughout the world (Figure 2) and is

generally considered a more water-efficient system compared with

the traditional flat basin because of (i) the speed with which water

is conveyed to the low end of a field [7]; and (ii) the relatively small

proportion of the soil surface is in contact with the flowing water

during irrigation than the basin [8]. Furrow bed irrigation system is

important in the current climate change scenario of

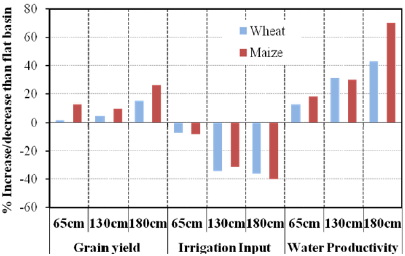

Figure 2: Advantages of furrow bed over flat basin [11].

Pakistan agriculture in particular and Himalaya region in

general due to the following reasons:

a) Furrow bed can save up to 50% irrigation water in

comparison with traditional flat basin thus can reduce impact

of limited water availability on crops in drought prone areas;

b) Furrows can quickly drain excess floodwater thus can

reduce crop damage in flood prone areas;

c) Furrow beds reduce crops lodging by providing safe path

and exit to speedy wind currents and greater reinforcement

due to strong roots and soil grip;

d) Furrow beds laid perpendicular to slope can increase soil

infiltration and ground water recharge by delaying runoff down

slope and providing larger surface water storage capacity in

furrows;

e) Conservation agricultural practices including minimum

tillage, ground cover/mulching etc can be conveniently adopted on furrow beds which reduce soil erosion and soil and water

degradation;

f) Furrow beds support mechanized farming thus can

increase crop production and can be adapted to technological

progress.

The Climate, Energy and Water Research Institute (CEWRI) of

Pakistan Agricultural Research Council (PARC) has played a pioneer

role in evaluation of furrow beds in Pakistan. Research conducted

has shown that furrow beds is effective in improving yield of wheat

by 20%, cotton 19%, Maize 58%, rice 26% compared with flat basin

or ridge irrigation systems [9,10]. Similarly, crop yield per unit area

increases by increasing the bed width. For instance, crop yield of

maize showed up to 15% increase while wheat crop showed 26%

increase on 180 cm bed size compared with flat basin [11], which

was the largest increase noted when compared with other bed sizes

given in Figure 2. Water saving of up to 50% in wheat, 30% in maize,

40% in cotton, 29% in rice were reported by N Ahmad et al. [9], Gill

et al. [10], Hassan et al. [12]. Increase in water saving by increasing

bed has been demonstrated in Figure 2 [9], which shows up to

40% and 36% increase in water saving by adopting 180cm bed

size for maize and wheat crops respectively. Furrow bed increase

crop yield and reduce irrigation application thus consequently crop

water productivity is increased. For instance, an increase in water

productivity of up to 70% in maize and up to 43% in wheat were

reported by Hassan et al. [12] and Akbar et al. [13]. Impact of bed

width on water productivity is illustrated in Figure 2, which shows

up to 70% and 43% increase in water productivity for maize and

wheat crops respectively compared with flat basin [13].

The CEWRI-PARC in collaboration with Australian Centre for

International Agricultural Research (ACIAR) played a pioneer role

in adopting furrow bed irrigation system in Maize wheat system

of Pakistan. Conservation agricultural practices involving minimum

soil disturbance were introduced in the form of permanent raised

bed (PRB) farming system. Different bed width and furrow sizes

were evaluated and demonstrated at farmer fields. Raised bed

machinery imported from Australia was indigenously produced.

The furrow bed farming system was disseminated by giving

incentive to the farmers in the form of giving subsidies in purchasing

raised bed machinery, training and demonstrations in the country.

Although there are still issues in the machinery, especially for

adopting PRB farming system, but the furrow bed system has been

adopted widely for maize, cotton, sugar beat and vegetables crops

throughout the country.

Sprinkler Irrigation Systems

In sprinkle irrigation method water is spayed into the air at

70-700 kpa (10-100 psi) pressure that fall on the ground or crop

canopy like rainfall [14]. Using sprinkle irrigation system, the crop

requirement can be accurately fulfilled through a combination

of measures involving careful selection of sprinkle nozzle size,

operating pressure and sprinkle spacing, thus adjusting sprinkle

application rate to suit the soil infiltration rate. Sprinkle irrigation

systems have increased importance for HKH region in the current

climate change scenario due to the following reasons:

a) Use limited available water more efficiently as the

application efficiency of a well-designed sprinkle system can

vary from 60-80% thus can increase crop production and

irrigated lands;

b) No land leveling required thus reduce operation cost and

protect environment by avoiding cutting and filling of cultivated

lands;

c) Irrigation of steep and rolling topography without

producing runoff or erosion;

d) Greater potential to increase agricultural production

by bringing extra undulating and sloppy HKH terrain under

irrigation;

e) Light shower can avoid crop damage due to temperature

extremes year around;

f) Timely irrigation of few centimeter using sprinkler

irrigation system can double crop yield at critical crop growth

stages, especially during wheat germination in HKH region;

g) The pre-sowing irrigation (Rouni) can be applied with

sprinkler system for timely planting of crops.

All these factors increase sprinkle irrigation system suitability

to the HKH region in the current climate change scenario. However,

there are few drawbacks. For instance, these systems are affected

by wind and, depending on the size of droplets and the spray

trajectory, uniform distribution may be limited. Sprinkle systems

have high initial costs and maintenance requirements. They also

use high operating pressures, which has large energy requirement.

The cost of portable and semi portable system is less but difficult

to operate due to movement of laterals. The CEWRI-PARC in

collaboration with local industries developed a complete range of

rain gun sprinkler irrigation systems, including diesel, electric and

PTO-driven pumping systems, couplers, other fittings and joints.

To keep the systems portable, the pumping unit along with power

unit (diesel engine, electric motor and solar panels) was mounted

on a trolley. These systems have been used in the Khanpur Dam

area where the rain gun sprinkler irrigation system is being used

for establishment of orchards, efficient irrigation of fruits and

vegetables, washing of Lychi and citrus, and for cooling and frost

control in orchards. Initial investment requirements and unreliable

electricity are restricting wider adoption of this technology.

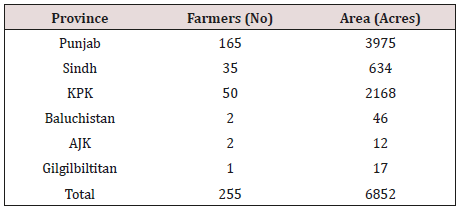

These rain gun sprinkler irrigation systems have been installed

in various parts of Pakistan for demonstration and introduction

of the technology. In rain fed areas, these systems are being used

for supplemental and life-saving irrigations to fruits, vegetables

and field crops. The research conducted by CEWRI-PARC resulted

in local fabrication of Poly Ethylene (PE) based irrigation system

components, sprinklers and high-pressure pumps. Based on

research findings and success of pilot-scale installations, the

Government of Pakistan launched a National Program entitled

“Water Conservation and Productivity Enhancement through High

Efficiency Irrigation Systems in Pakistan” during 2007-12. Drip

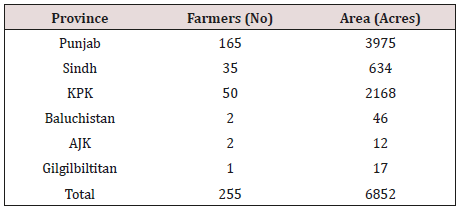

and sprinkler irrigation systems were installed on an area of 6852

acres in all provinces (PARC 2010). The major area was in Punjab

and followed by KP. There were 255 farmers benefitted from the

project. There were 80 % sprinkler irrigation systems and 20 %

were drip system during the period (Table 4).

Table 4: Drip and sprinkler irrigation systems in provinces,

installed under the national project (from 2007-2012).

Drip Irrigation Systems

Drip irrigation system applies water close to each plant and

the application uniformity depends on the uniformity of discharge

from the emitters [14]. It generally comprises of a pumping station,

control head, main and sub main lines, lateral lines, emitters, valves

and fittings. The drip irrigation system has special agronomical, agro

technical and economic advantages that make it a suitable option of

irrigation in the HKH and adjoining region. These advantages are

as under:

a) Drip irrigation can conveniently and efficiently supply

water directly to the individual crop rows or plants, thus can

effectively utilize small continuous streams of water in the HKH

region;

b) It reduces water requirement by saving up to 50%

irrigation water to a young orchard as compared to sprinkle

or surface irrigation methods thus can enhance community

resilience to drought;

c) It requires less labor, as a well-regulated system can

effectively utilize a continuous stream of water, a norm in

HKH region, with less farmer supervision thus can increase

production;

d) It discourages weeds growth and offers greater control

over fertilizer placement and timing thus can save farmer

resources;

e) Drip irrigation can be designed for any topography even if

the area is rocky with steep slopes and plants are with irregular

spacing, which increase its importance for HKH region.

Drip irrigation systems have shown yield gains of up to 100%,

water savings of up to 40–80%, and associated fertilizer, pesticide,

and labor savings over conventional irrigation systems [15]. The

low rate of water application reduces deep percolation losses.

The systems have lower energy requirements than sprinkler

systems because of lower operating pressure requirement. The

water application uniformity of locally developed drip irrigation

system was above 85 % [16]. Evaluation of drip systems at CEWRIPARC

showed lowest coefficient of variation of locally developed

microtube emitters [17] with application uniformity above 85 per

cent [16]. This shows that trickle irrigation systems have potential

to use scarce water resource more efficiently if designed properly.

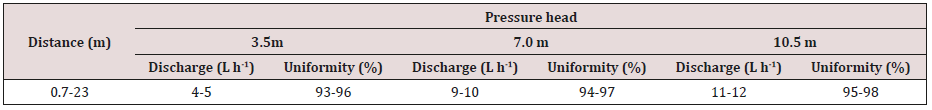

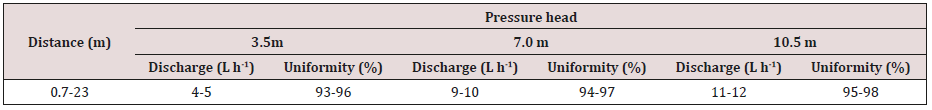

The evaluations by Ahmad MM et al. [18] indicated that drip system

with micro tube emitters can be operated at low pressure head (3.5

m) with an insignificant loss in uniformity as compared to operating

at high pressure head (10 m), which can save energy cost, as given

in Table 5. This low head drip system is being used for small scale

vegetable production in Pakistan.

Table 5: Microtube emitter discharge and water application uniformity at various pressure heads and distances Ahmad et al. [9].

These research outcomes are currently being disseminated

through training and demonstration in provinces. The provincial

governments are adopting drip/sprinkler systems evidenced

through various programs, indicating government commitment

for accelerating drip/sprinkler system adoption. By successful

adoption of these technologies, more water can be saved or

efficiently used along with an increase in yield. The saved water

will automatically reduce over exploitation of groundwater and

consequently mitigating the secondary salinity by improving

overall water use efficiency of the irrigation system. This shows

that the system has potential to use scarce water resource more

efficiently if designed properly.

Conclusion and Recommendations

a) Lack of adoption of climate change resilient practices in

the hill ecology of HKH region is negatively affecting their food

security and also have negative implications for the irrigated

agriculture downstream in adjoining countries;

b) The 51% area of Pakistan falls in HKH region, thus was

considered as a representative case example for analyzing

their agricultural production system, growing food security

and climate change issues and promising climate resilient

interventions mainly adopted in downstream leveled irrigated

areas of HKH region;

c) Furrow bed, sprinkler and drip irrigation systems

has been shown efficient irrigation methods with multiple

advantages thus can be instrumental for improving community

resilience to climate change by conserving the declining and

uncertain available water resources in the hill ecology of HKH

region;

d) However, adoption of these technologies is equally

important for improving climate change resilience, food

security and livelihood of the hill ecology of HKH region.