Lupine Publishers | Journal of Advances in Robotics & Mechanical Engineering

Abstract

Food losses in perishable fruits are present worldwide and in many cases half of the fruit harvested is lost. Drying is the oldest and most common food conservation process that increase product shelf life. However, some nutritional properties can be lost if dryer variables are not properly controlled. Heat pump drying (HPD) is useful for food products having high initial moisture as the dryer keeps the air relative humidity beneath 20%. A monitoring system was developed to check the homogeneity of each of the apple slices within a tray. The system touches all the slices within one row, before it moves to the next one. Product moisture was measured with a bifurcated optical fiber that acquired the 950nm and 800 nm wavebands and converted them to electrical signals with photodiodes. Surface plots show moisture measurements taken once the tray was inserted and two hours later.

Keywords: Heat Pump Dryer; Apple Slices; Moisture Fiber Optic Sensing; Product Temperature Sensing

Introduction

Half of all the fruit and vegetables produced worldwide are

lost or wasted, representing 1.3 billion tons annually [1]. Fruit

processing is becoming necessary to avoid its spoilage. Food

dehydration is a common food conservation practice for increasing

fruit shelf life. This technique maintains product sensorial attributes

and can be easily transported worldwide after proper packing [2].

Drying removes free water from food reducing microbial spoilage

and enzymatic reactions [3]. Food drying has been extensively

studied in the last years trying to obtain high drying rates while

maintaining product quality [4]. Energy consumption during

drying has to be optimized, meanwhile fruit texture, flavor and

chemical components persist [5]. Drying consumes 10-15% of the

total industrial energy demand in Canada, France, and the USA [6].

Solar and hot air drying are the most common used methods due

to their simplicity, but their performance is questionable due to

long drying time and poor energy efficiency [5,7,8]. Total energy

consumption in drying apple slices increased with air velocity and

decreased with air temperature. Its energy efficiency varied from

2.87 to 9.11% [9]. Postharvest studies in the United States indicate

that 8.6% fresh apples are lost at retail and 20% at consumer level

[10]. Apple dehydration methods include solar, tunnel, microwave,

infrared and freeze drying [11]. Hot air circulates through trays

enclosed in a cabin and the poor drying and energy efficiency

depends on air speed and heaters [5-9,11,12]. High quality food use

vacuum-microwave and Refractance Window drying [13] due to its

better energy efficiency.

Heat pump technology has been used to dry food based on

dehumidification/heating principles. Heat pump drying (HPD) has

been found to be more effective in drying materials with high initial

moisture and in very humid places [14]. Heat pump drying is now

encountered in food industries due to its low energy consumption,

minimum quality loss and high drying performance. HPD dries

fruit with lower air temperature and relative humidity preserving

heat-sensitive vitamins [15,16]. A system composed of a solar and

a HPD dryer combination can be more efficient [17]. Solar drying

can take place in daytime meanwhile heat pump drying can be

effective at night. Fruit slices are introduced in trays and require

from continuous temperature and moisture sampling. Single-point

spectroscopy in the visible and near infrared region (Vis-NIR) [18] is

a non-destructive technique used to monitor quality changes in the

food industry. In a study carried out with mango it was found that

at the 532 and 785 nm wavebands, moisture changes were detected [19]. Reflectance to transmittance ratios in the photosynthetic

domain at 555 nm represent a cost-effective alternative for water

stress and quality estimation in maize [20]. The reflectance regions

at 765–784 nm, and 950–957 nm is described as water absorption

wavebands [21,22]. In this paper we describe an automatic system

for sampling moisture and temperature of apple slices within a heat

pump dryer. A mechanism was designed to move the sensors and

measure both air and product variables.

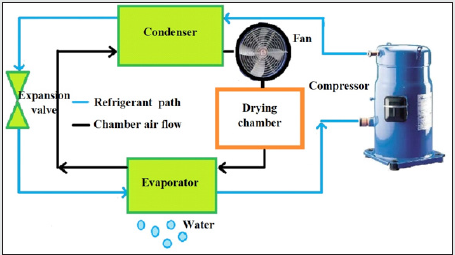

Heat Pump Dryer

The block diagram of the heat pump dryer (Figure 1) shows the refrigerant cycle being its path highlighted by a blue line. The refrigerant components are a SM120S4VC scroll compressor, a condenser, an evaporator, and an expansion valve [17]. Airflow within the drying chamber circulates through the evaporator and the condenser as shown by the black line in Figure 1. Fans make airflow circulation possible.

Air Temperature, Air Relative Humidity and Slice Temperature Sampling

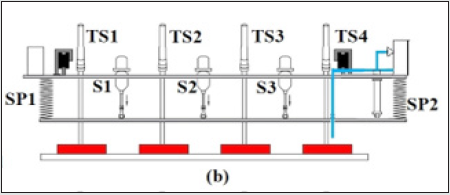

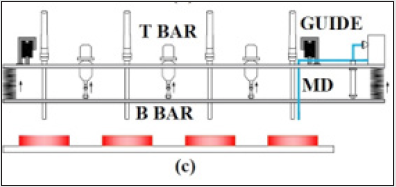

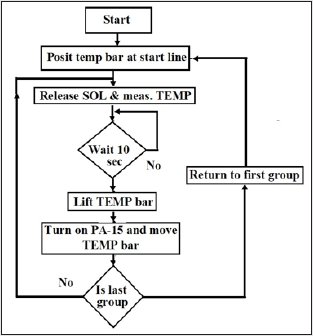

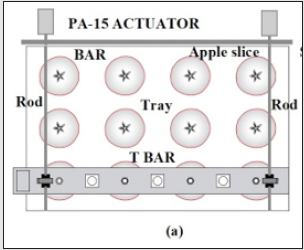

Air temperature and relative humidity were measured with DHT22 sensors (Adafruit, Australia). The sensor uses a capacitive circuit to measure air humidity and a thermistor to measure temperature. There were 5 circuits installed inside the dryer hanging between the top bar (TBAR) and the bottom bar (BBAR), (Figure 2a). These circuits were connected through an I2C connection to an Arduino UNO microcontroller, sampling air variables every minute. Dryer control based on product temperature demands less energy than with air temperature control. Therefore, a prototype was designed to measure food temperature by contact using J type thermocouples (TS1-TS4). In Figure 2 only 4 thermocouples are shown, but the prototype used five sensors per row. The main elements used by the automatic monitoring process were a linear actuator, three solenoids (S1-S3) and two rectangular bars separated by springs (SP1, SP2). The bottom bar has the thermocouples fixed (Figure 2b), and the metal rod plunger of the solenoids welded. After releasing the 120 V solenoids the sensors touch the apple slices and measure their temperature (Figure 2b). When the solenoids are energized, the bottom bar is lifted (Figure 2c) and the bars are free to move, letting a distance of 10 mm between the apple slices and thermocouples. A linear actuator (PA 15, Progressive Automations, USA) with a 12 V brushed DC motor was employed to move the thermocouple bar back and forth. Apple slices measurements were done automatically and uses a microcontroller (Arduino UNO) to provide sampling time and actuator voltage. When the TBAR is over the 5 apple slices of the first row and the solenoids are turned-off, the J-thermocouples touch the slices (Figure 2b, Figure 3). The springs will maintain the bottom bar (BBAR) down and temperature measurements of five slices are taken simultaneously at the first row. After 10 seconds, energy is supplied to the solenoids lifting the BBAR. A voltage pulse is applied to the PA-15 actuator until it arrives to the second row of apple slices, being the sampling process repeated. An optical sensor was developed (Figure 4a) to detect moisture in apple slices. Two hundred samples were acquired from random apple slices using a Vis-NIR spectrometer (USB2000+, Ocean Optics Inc. USA). After analyzing the spectral signatures with discriminant analysis, the best wavebands for moisture detection were 950 nm and 800 nm.

Figure 2b: Prototype used to measure fruit temperature showing lateral view with released solenoids.

Figure 2c: Prototype used to measure fruit temperature showing lateral view after solenoids activation.

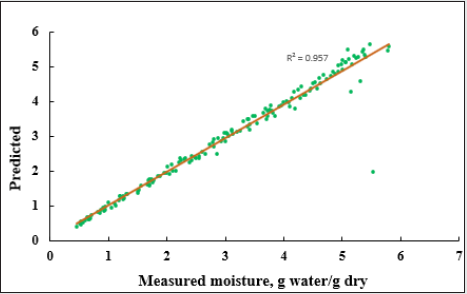

A light source illuminates the bifurcated optical fiber system at one end and reflected light from the sample is obtained at the other fiber end (Figure 4a). The reflected light arrives to a NIR beam splitter (mod 47-123, Edmund Scientific, USA), that outputs two identical 50R/50T reflectance and transmission optical beams (Figure 4b). Each beam is filtered by a band pass filter (mod 65-118 for 800 nm and mod 88-569 for 950 nm, Edmund Scientific, USA). The optical information is directed to photodiodes and converted to electrical signals. After amplifying the photodiode signals with two precise, zero-drift operational amplifiers (LTC1050, Linear Technology Inc., USA) it is acquired by an Arduino UNO microcontroller and saved in memory. The PIN photodetector (PS7- 5, First Sensor Inc., USA) was used for 800 nm detection, meanwhile a precise PIN photodiode (S1223, Hamamatsu Inc., Japan) detected the 950 wavebands. Two hundred apple samples were measured at different drying stages with the optical sensor, weighted with a balance and then dried in an oven to obtain the dry weight without water. A linear curve resulted between real and optical moisture measurements having a R2 of 0.957 (Figure 5).

Figures (4a,4b): Optical fiber sensor (a) detects apple slice moisture, being (b) composed of a beam splitter, filters, and photodiodes.

Figure 5: Optical fiber sensor measurement correlated apple slice moisture given in grams of water against grams of dried solid content.

Results

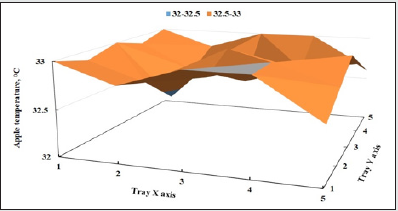

Apple slices 6 mm thick were cut filling three trays of the HPD dryer. Only the top tray was monitored as the surface over it let a space for the prototype movement. Air temperature was of 40°C and air relative humidity 20%. These measurements were taken with the DTH22 sensors and were constant during the entire 250 min drying time. Temperature measurements taken with the prototype showed apple slice variations after 90 minutes of drying (Figure 6). Temperature of the 25 slices varied from 32.4 to 33°C. The X and Y axis number represents the slice number given in cartesian format (1,1; 3,4). The first case (1,1) represents the apple slice in the first row, being at left position. The second case (3,4) shows the middle apple slice (3) of the fourth row.

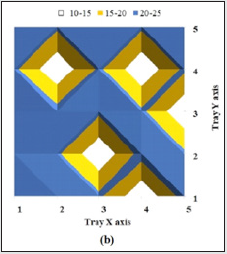

Optical fiber and photodetectors have been used to monitor chemical concentrations [22]. Optical moisture measurements were taken to 25 samples positioned over the top tray. Once the dryer was hot and the trays introduced, the 25 apple slices of the top tray had moisture content values between 76 and 78% (Figure 7a). After drying for 120 minutes, the slices reduced their moisture content considerably to values within 18 and 22% (Figure 7b). The slices at (2,4; 3,2 and 4,4) were smaller and shrinked quickly [23]; optical measurements were not taken over the fruit surface and their values were below 11% [24].

Conclusion

This work shows an automatic system for drying apple slices. It measures temperature and moisture content of the fruit during the drying process as it can provide a better signal for energyefficient dryers. The system can include more thermocouples and use instead infrared sensors avoiding solenoid lifting and releasing. The moisture optical sensor used 800 nm and 950 nm waveband filters. The optical sensor can be transformed to measure another fruit nutrients during drying by changing the waveband of the filters.

Acknowledgements

We would like to acknowledge all the technical staff of the University that provided funding to build the prototype. As well we would like to thank MI Angel Hernandez Facundo for his help in the development of all the drawings.

Read More About Lupine Publishers Journal of Advances in Robotics & Mechanical Engineering Please Click on the Link Below:

No comments:

Post a Comment

Note: only a member of this blog may post a comment.