Lupine Publishers- Trends in Civil Engineering and its Architecture

This method of Lightweight floor construction does not require the

use of heavy concrete screeds. It consists of a layer of hard

thermal insulation on which the tile flooring is directly mounted,

usingan adhesive mortar reinforced with a glass fiber mesh.

This article summarizes the current results of the strength tests of

this radiator model with XPS thermal insulation for bending,

compression and point compression with a variety of constructional

models. Application in all tests of various types and structures

of insulating panels, with the use of glass fiber mesh and without it,

allowed us to check and compare the most important strength

parameters with different variants. At the same time, the principle of

accepting materials that produce results guaranteeing the

quality, durability and optimal price of the lightweight floor model

with the use of a heating coil was followed.

Keywords: Compressive strength; Bending strength; Lightweight radiant heater; Cement adhesive

In 2016 experimental studies on heat flux density and thermal

inertia of light radiant heaters, described in [1] and [2], were

completed. At the turn of 2016/2017, static shear strength, peel

force, pull-off strength, shearing tests, absorbability and frost

resistance tests were carried out on insulated EPS polystyrene

insulation boards and extruded waffle type XPS with dissipating

elements, using polyurethane adhesive [3]. This article describes

compressive and bending strength in construction consisting of

porcelain tiles, mounted to thermal insulation EPS or XPS through

cement adhesive C2S1, both with and without the use of embedded

glass fiber mesh. The latest tests on the strength of this radiator

heater with XPS thermal insulation for bending, compression and

point compression, with or without a glass fiber mesh, and with

the use of PE/RT/Al/PE/RT PVC heating pipe with a diameter of

16x2mm, or without it, was made at the Białystok University of

Technology.

1. XPS300 with pipe / Sika Ceram 255 / tile,

2. XPS300 only / Sika Ceram 255 / tile,

3. XPS300 with a groove without pipe / Sika Ceram 255 / tile,

4. XPS300 with pipe / Sika Ceram 255 / no tile,

5. XPS300 only / Sika Ceram 255 / no tile,

The same systems as above were tested but without the use of a mesh.

Compressive strength and point compression were tested on a model with dimension 80mm (width) x 100mm (length) x 50mm (height) with tile and 80mm (width) x 100mm (length) x 42mm (height) without tiles, using speed pressure of 4mm / minute. In the compression test, a pressing and supporting steel stamp with a circular surface larger than the surface of the samples was used, and in the point compression test 20x20mm steel stamp was used. The following sample models were tested:

1. XPS Synthos 300 / Sika Ceram 255 with a mesh of 335g/ m2/ tile

2. XPS Synthos 300 / Sika Ceram 255 without a mesh of 335g/m2 / tile

3. XPS Synthos 300 / Sika Ceram 255 with a mesh of 335g/ m2 /no tile

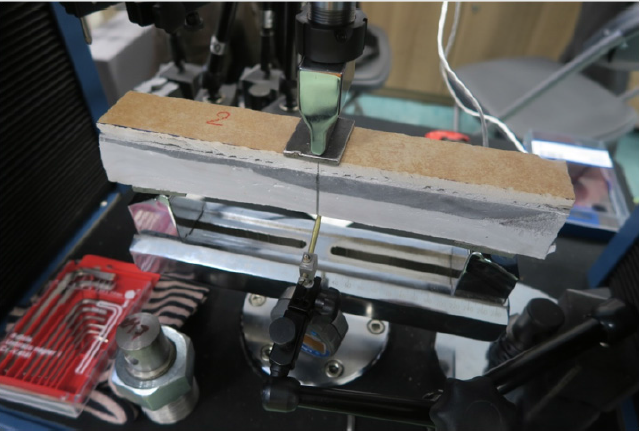

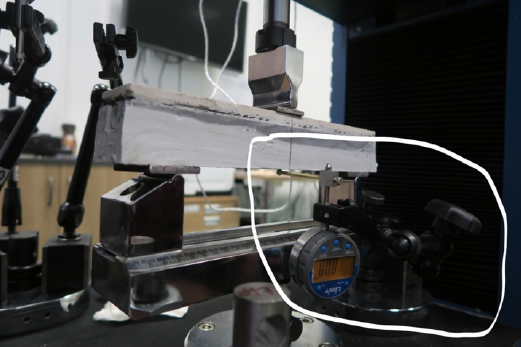

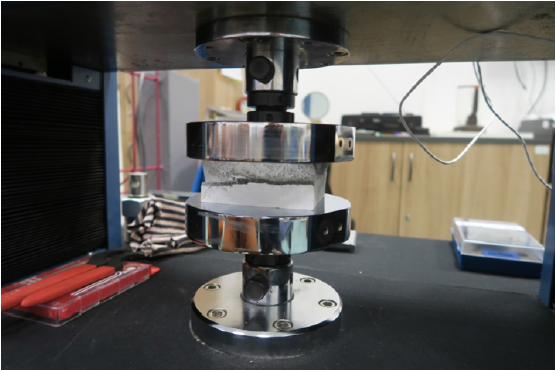

The test stand and tooling are shown in Figure 1-4.

This article closes the cycle of basic tests of mechanical

strength over the so-called light-radiant heater in which no type

of screed occurs. The aim of the experiments was to determine

the possibility of installing this heater in accordance with Article

5.1 of the Construction Polish Law [4]. The model of this radiant

heater consists of a thermal insulation layer with grooves in which

heating pipes are placed. A coil is inserted into the grooves, and all

floor surface is covered with a cement adhesive in a system without

metal diffusion plates or polyurethane glue with these metal

plates. Adhesives, and their reinforcement in the form of fiberglass

mesh, were adopted, which according to the technical description

of manufacturers can be used in such radiant heaters on difficult

substrates.

Various lightweight heater designs were investigated, using a hard, easy to process thermal insulation with a minimum compressive stress of 200kPa (EPS) and 300kPa (XPS), with a bending strength of minimum 250kPa (EPS) and 300kPa (XPS), according to the Declaration of Properties Utility given by manufacturers and adequately guaranteed standards [5] and [6]. To reinforce the cement adhesive layer, a glass fiber mesh was used on which the most popular type of flooring - tile (stone) was laid. We can use it with underfloor heating or possibly a wall covering in wet rooms. This article summarizes new experiments that were carried out on samples of the entire heating model during bending, surface compression and point compression (puncture), in accordance with the construction described in point. 2., under operating conditions.

The maximum bending force resulting in the destruction of the model with the mesh was on average about 1.1kN, and without it about 0.48kN in different variants - with a mounted coil, without it or with an empty groove. At the same time, this gives a result at least two times better for the radiator construction with mesh reinforcement. The use of a mesh is not so important in compressive strength tests and puncture. The maximum compressive force was 3kN on average, regardless of whether the radiator was reinforced with mesh or not, while the puncture force in the structure with the mesh was on average 3kN, and without it 2.33kN.

Destruction of the samples during the bending strength test occurred at the lowest deflection (elongation) of 10.1mm (sample with mesh) and 8.9mm (sample without mesh) with the axial spacing of supports 220mm. According to the standard [7] for concrete structures calculation of deflections are not necessary if the deflection arrow of a beam, plate or bracket under load exceeds 1/250 of the span. In the previous Polish standard [8] for beams, slabs and flat roofs, the limit values of deflections could not exceed l/200 or 30mm with the construction spans 6-7,5m. In accordance with the above standards, the deflections of the main building structures referring to the tested samples in which the spacing of supports was 220mm can be maximum 220mm/250 = 0.9mm or 220mm/200 = 1.1mm. Deflections in the tests amounted to at least 10 times more, from 9mm to even 32mm. In the case of wooden structures described in the standard [9], the limit deflection arrow is the higest for beams based on 2 supports - l/150 or for the bracket - l/75, including the inverse deflection. It follows that the maximum deflections in relation to our samples can be 220mm/150 = 1.47mm or 220mm/75 = 2.93mm. It is still 3 times lower than the results achieved in the tested samples from 8.9mm upwards. This means that the construction of the light floor is very flexible and is able to bending more, without cracks than all acceptable standard deflections in both, concrete and wooden structures.

The maximum compressive force was not less than 2.6kN, and its average value in operating conditions after 30 days was 3.1kN. This gives us, per m2, a strength of not less than 325kN/m2. At very high compressive force, the samples of the lightweight radiant heater were not destroyed, they were subject only to progressive flattening (deflection). This means there is great resistance of such a radiant heater to any variable payloads found in construction works, including those subjected to dynamic loads. The tested values confirm the compression strength of XPS 300 insulation boards, declared by manufacturers, amounting ≥300kN/m2, in accordance with the standard [6]. This result is very high when we want to compare it to what is projected on the basis of the standard [10]. Utilitarian loads for the rooms, bedrooms of residential buildings and waiting rooms in hospitals, bedrooms in hotels, kitchens and toilets, are only 2kN/m2, or rooms with tables (in schools, cafes, restaurants, canteens, reading rooms, receptions, waiting rooms) 3kN/m2, and the maximum included in this standard with the area generally accessible to the crowd (in public buildings, concert halls, sports halls with stands, terraces, access points and railway platforms) amount to 7.5kN/m2. The maximum tested force under point compression with an area pressure of 4cm2 imitating the legs of a chair or table using a glass fiber mesh was not less than 2.9kN.

The bending strength of a radiant heater without

screeds is made higher by using cement adhesives with

a glass fiber mesh. As already pointed out in an earlier

article [11], the cost of the fiber mesh does not have

a significant impact on the price of the entire lightweight radiant

heater.

The lightweight, not require screed floor is flexible enough to meet the standard requirements regarding the serviceability limit state at the deflections of concrete structures and wooden structures. It can be dedicated to all types of construction objects, both residential and sacral, sports, and other public utilities, and in industrial buildings with storage and production areas, depending on the loads determined to take into account the intended use and equipment installed. In the case when it can be expected that resonance effects will occur as a result of synchronous, rhythmic movement of people (eg dances, jumps), it is recommended that the calculation model be determined on the basis of a special dynamic analysis contained in [10].

Assuming placing on the floor a table with 4 legs, each with an area of 4cm2, the tested heater is able to transfer the maximum load of over 11kN. During work, when the floor is not yet laid, the maximum point load on the surface of 4cm2 should not exceed 1kN. Under normal conditions of use, there are no such heavy loads.

This article closes the cycle of basic strength tests of a light, thin radiant heater without screeds, and confirms the possibility of its use in all construction objects. I suggest adding to the current experiments new adhesion tests of type C2S2 cement adhesive, with 2 times greater deformability. This will allow a comparison with the results of the tested polyurethane adhesive strength, and give an answer to the question of whether it will be possible to use it outside of buildings, in snow and ice protection systems.

The author of the article would like to thank Mrs. Anna Zakowicz

and Mr. Tadeusz Chyzy from the Bialystok University of Technology

for providing laboratories.

https://lupinepublishers.com/civil-engineering-journal/pdf/TCEIA.MS.ID.000166.pdf

To Know More About Open Access Publishers Please Click on Lupine Publishers

Abstract

Keywords: Compressive strength; Bending strength; Lightweight radiant heater; Cement adhesive

Introduction

Description of the measurement stand and research methodology

The tests were carried out in the laboratory at the Białystok University of Technology. The research included bending strength, compression and point compression of samples in different variants, using the XPS300 insulating board, a Synthos waffle. Bending strength was tested on the model of the size 45mm(width) x300mm(length) x 50mm(height) with tile, and dimensions 45mm(width)x300mm(length) x42mm(height) without tiles. For bending, we used steel support set with surface 40x45mm and axial spacing of 220mm, and steel pressing stamp of 35 x 47mm, all for 10 models. The first five models were tested with a glass fiber mesh 335 g/m2, embedded in the cement mortar as follow:1. XPS300 with pipe / Sika Ceram 255 / tile,

2. XPS300 only / Sika Ceram 255 / tile,

3. XPS300 with a groove without pipe / Sika Ceram 255 / tile,

4. XPS300 with pipe / Sika Ceram 255 / no tile,

5. XPS300 only / Sika Ceram 255 / no tile,

The same systems as above were tested but without the use of a mesh.

Compressive strength and point compression were tested on a model with dimension 80mm (width) x 100mm (length) x 50mm (height) with tile and 80mm (width) x 100mm (length) x 42mm (height) without tiles, using speed pressure of 4mm / minute. In the compression test, a pressing and supporting steel stamp with a circular surface larger than the surface of the samples was used, and in the point compression test 20x20mm steel stamp was used. The following sample models were tested:

1. XPS Synthos 300 / Sika Ceram 255 with a mesh of 335g/ m2/ tile

2. XPS Synthos 300 / Sika Ceram 255 without a mesh of 335g/m2 / tile

3. XPS Synthos 300 / Sika Ceram 255 with a mesh of 335g/ m2 /no tile

The test stand and tooling are shown in Figure 1-4.

Figure 1: Measuring stand of Hung Ta Instrument Co. Ltd to test the bending and compression strength.

Measurements

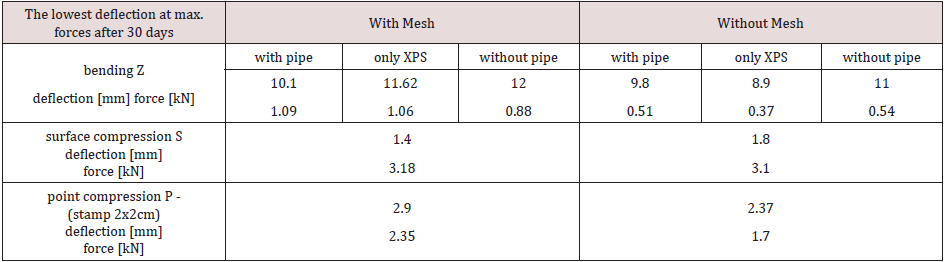

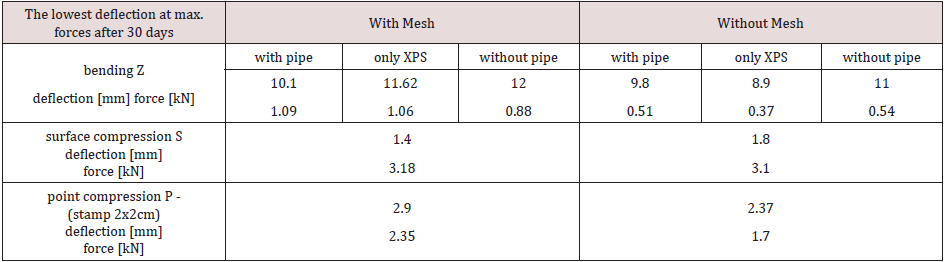

Maximum stresses causing destruction of samples and their smallest deflections when testing bending strength Z, compression S and point compression P of a radiant heating model, made of thermal insulation from waffles XPS, according to the construction described in item 2 of this article, is shown in Table 1. Value the Z, S and P strengths of the lightweight floor with the tiles are given under operating conditions (30 days from sample preparation).

Table 1: Results of bending, surface, and point compression tests of a lightweight floor made on XPS insulation.

Analysis of Results

Various lightweight heater designs were investigated, using a hard, easy to process thermal insulation with a minimum compressive stress of 200kPa (EPS) and 300kPa (XPS), with a bending strength of minimum 250kPa (EPS) and 300kPa (XPS), according to the Declaration of Properties Utility given by manufacturers and adequately guaranteed standards [5] and [6]. To reinforce the cement adhesive layer, a glass fiber mesh was used on which the most popular type of flooring - tile (stone) was laid. We can use it with underfloor heating or possibly a wall covering in wet rooms. This article summarizes new experiments that were carried out on samples of the entire heating model during bending, surface compression and point compression (puncture), in accordance with the construction described in point. 2., under operating conditions.

The maximum bending force resulting in the destruction of the model with the mesh was on average about 1.1kN, and without it about 0.48kN in different variants - with a mounted coil, without it or with an empty groove. At the same time, this gives a result at least two times better for the radiator construction with mesh reinforcement. The use of a mesh is not so important in compressive strength tests and puncture. The maximum compressive force was 3kN on average, regardless of whether the radiator was reinforced with mesh or not, while the puncture force in the structure with the mesh was on average 3kN, and without it 2.33kN.

Destruction of the samples during the bending strength test occurred at the lowest deflection (elongation) of 10.1mm (sample with mesh) and 8.9mm (sample without mesh) with the axial spacing of supports 220mm. According to the standard [7] for concrete structures calculation of deflections are not necessary if the deflection arrow of a beam, plate or bracket under load exceeds 1/250 of the span. In the previous Polish standard [8] for beams, slabs and flat roofs, the limit values of deflections could not exceed l/200 or 30mm with the construction spans 6-7,5m. In accordance with the above standards, the deflections of the main building structures referring to the tested samples in which the spacing of supports was 220mm can be maximum 220mm/250 = 0.9mm or 220mm/200 = 1.1mm. Deflections in the tests amounted to at least 10 times more, from 9mm to even 32mm. In the case of wooden structures described in the standard [9], the limit deflection arrow is the higest for beams based on 2 supports - l/150 or for the bracket - l/75, including the inverse deflection. It follows that the maximum deflections in relation to our samples can be 220mm/150 = 1.47mm or 220mm/75 = 2.93mm. It is still 3 times lower than the results achieved in the tested samples from 8.9mm upwards. This means that the construction of the light floor is very flexible and is able to bending more, without cracks than all acceptable standard deflections in both, concrete and wooden structures.

The maximum compressive force was not less than 2.6kN, and its average value in operating conditions after 30 days was 3.1kN. This gives us, per m2, a strength of not less than 325kN/m2. At very high compressive force, the samples of the lightweight radiant heater were not destroyed, they were subject only to progressive flattening (deflection). This means there is great resistance of such a radiant heater to any variable payloads found in construction works, including those subjected to dynamic loads. The tested values confirm the compression strength of XPS 300 insulation boards, declared by manufacturers, amounting ≥300kN/m2, in accordance with the standard [6]. This result is very high when we want to compare it to what is projected on the basis of the standard [10]. Utilitarian loads for the rooms, bedrooms of residential buildings and waiting rooms in hospitals, bedrooms in hotels, kitchens and toilets, are only 2kN/m2, or rooms with tables (in schools, cafes, restaurants, canteens, reading rooms, receptions, waiting rooms) 3kN/m2, and the maximum included in this standard with the area generally accessible to the crowd (in public buildings, concert halls, sports halls with stands, terraces, access points and railway platforms) amount to 7.5kN/m2. The maximum tested force under point compression with an area pressure of 4cm2 imitating the legs of a chair or table using a glass fiber mesh was not less than 2.9kN.

Conclusion

The lightweight, not require screed floor is flexible enough to meet the standard requirements regarding the serviceability limit state at the deflections of concrete structures and wooden structures. It can be dedicated to all types of construction objects, both residential and sacral, sports, and other public utilities, and in industrial buildings with storage and production areas, depending on the loads determined to take into account the intended use and equipment installed. In the case when it can be expected that resonance effects will occur as a result of synchronous, rhythmic movement of people (eg dances, jumps), it is recommended that the calculation model be determined on the basis of a special dynamic analysis contained in [10].

Assuming placing on the floor a table with 4 legs, each with an area of 4cm2, the tested heater is able to transfer the maximum load of over 11kN. During work, when the floor is not yet laid, the maximum point load on the surface of 4cm2 should not exceed 1kN. Under normal conditions of use, there are no such heavy loads.

This article closes the cycle of basic strength tests of a light, thin radiant heater without screeds, and confirms the possibility of its use in all construction objects. I suggest adding to the current experiments new adhesion tests of type C2S2 cement adhesive, with 2 times greater deformability. This will allow a comparison with the results of the tested polyurethane adhesive strength, and give an answer to the question of whether it will be possible to use it outside of buildings, in snow and ice protection systems.

Acknowlegement

To Know More About Open Access Publishers Please Click on Lupine Publishers

Follow on Linkedin : https://www.linkedin.com/company/lupinepublishers

Follow on Twitter : https://twitter.com/lupine_online

No comments:

Post a Comment

Note: only a member of this blog may post a comment.