Lupine Publishers| Journal of Civil Engineering and its Architecture

Abstract

The aim of this study is the use of local materials (plaster, sand dunes and date palm fiber) for the region of southern Algeria. By expand areas of the use of these materials in the field of construction. Despite the large ament of gypsum, its use is limited to some secondary operations like coatings and decorative elements. The sand dunes and palm fiber, its use in the construction are very limited. In this study, the sand dunes and palm fiber was added to plaster, to find the mortar that has physical and mechanical properties that allow its use in construction. The results obtained showed that the addition of date palm fibers improves the physical properties (density, water absorption, etc.) and mechanical properties (compression strength, flexural strength, etc.).

Introduction

The Algeria, especially the South, is rich in natural materials, which can then be used directly in the construction field he must study their properties in order to extend their use. Among these materials, which can be exploited, and that we will consider, plaster, sand dune, and the fibers of the Palm. The use of vegetable fibers in the reinforcement of building materials to improve certain properties, it is the most used technology currently, because these results and to expand the use of eco-materials. Algeria has unlimited sources of vegetable fibers (of Palm, Alfa Abaca, hemp, Cotton,), but their use in the construction of the almost non-existent field. The incorporation of the fibers of date palm in the mortar of plaster, is carried out in order to improve the tensile strength and decrease its fragility. The major assumption that the fibers allow the judgment of the cracking mechanism, delaying the start of the crack and the controlling once it appears. In our study, we will examine the effect of the addition of fibers of palm trees date palm to the physical and mechanical properties of the Mortar plaster. Where we are looking at the impact of the rate and length of the fibers of date palm on the characteristics of mortar plaster, in the short and in the long term.

Materials used

The Materials used are those available at the local level:

Sand Dunes used: In our study we used the sand dunes of Guerrera (GHARDAIA). The physical properties of sand dunes used are represented in Table 1.

Mixing water: The used mixing water is the public drinking water of the network of the city of Ghardaia.

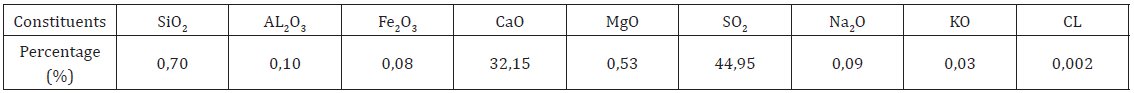

Lime: Air lime as a retardant of setting time of the plaster was used, because it decreases the solubility of the latter and allows to increase the time of employment. In addition it does not affect these mechanical properties. A chemical analysis of the lime used was performed using the method of diffractometer by X-rays in the lab. Physics at the University of Laghouat, the results of this technique are presented on the diffractogram me below [1] (Figure 1).

Fibers: The fibers used are vegetable fibers of DOKAR of date palm in the region of Ouargla. The Spectrochemical Analysis of the powder of the fibers after calcination at 400°C gave the following elements [2]. The fibers used with the following characteristics [3] (Tables 2 & 3)

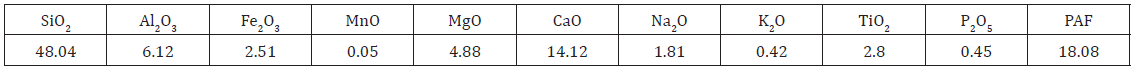

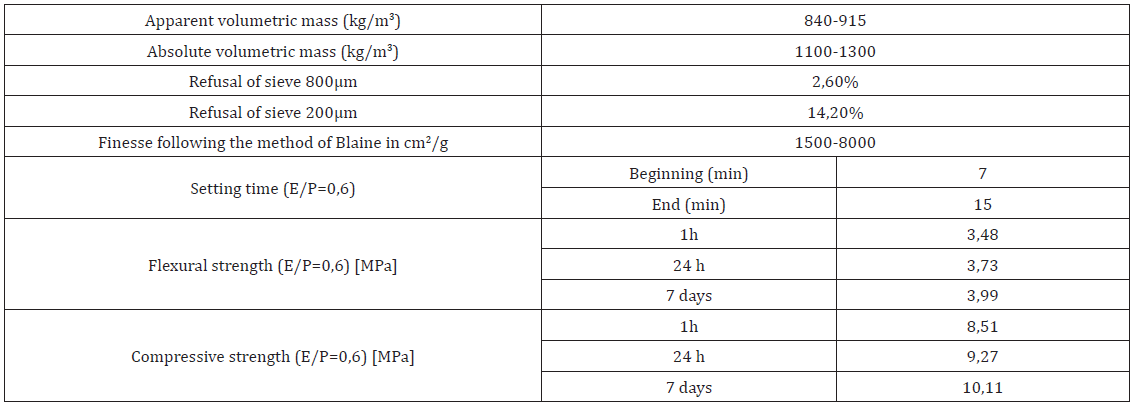

Plaster: The used plaster is a local product taken from the career of oasis in Ghardaia. It is available in the market. The chemical analysis is summarized in the Table 4. We can summarize certain essential properties in the Table 5, to identify the plaster (Table 5).

Formulation of Plaster Mortar with Fiber: The determination of the composition of mortar plaster reinforced with fibers of date palm, we used the same composition with the classic mortar, so we take the following composition:

I. We take the report E/(P+S) = 0.6.

II. The report of S/P is set to the value 0.5.

III. They add 6 % limes air as retarding of setting time.

IV. After the preparation of fibers of date palm, we respect the recommandations of Kriker [2], for this, the fibers used are treated in the water, then dried in the free area.

V. The mixing is carried out in the following way.

VI. We are mixing first of all the Sand and fibers to sec.

VII. The plaster is added, while blending it well with the sand and fibers.

VIII. It adds the mixing water and lime and malaxant well the mixture.

Confections of Samples and Storage Conditions: After the mixing, it fulfils the mussels to reason of two layers and vibrate the mortar using a rod to ensure a good distribution and a proper orientation of the fibers, and finally grind and smooth the surface of the mortar. The test pieces are assembled, they are placed in the open air in the laboratory. After 24 hours, these are removed and placed in free air at a temperature of (25°C±1°C) up to the time of the test, this procedure is made for all the compositions and for all tests.

the samples used are (4x4x16)cm3 for the following tests.

i. Determining the density.

ii. Absorption of water.

iii. Tensile strength.

iv. Compression strength.

Composition of mortar of plaster reinforced by fibers of date palm: To get a good composition of mortar plaster reinforced with fibers of date palms, we follow the following steps:

First of all, we use the same composition of pate of mortar base of plaster, which we have obtained in the step above.

a. As regards the fibers we tried to determine.

b. First of all the mass fraction optimal fiber to introduce in the mortar of plaster using the fibers of the date palm to a constant length L=10mm and by increasing the dosage of fiber from 0% to 2% with a step of 0,5% by mass.

c. And then, the optimal length for the optimal fraction that we found previous for each length, 10mm, 20mm, 30mm, et 40mm.

Laying all tests, that we were conducting, keep well the workability of dough into court of sitting time. Because the addition of plant fibers to a mineral matrix leads to a decrease in workability.

All the samples are retained in the ambient air of the laboratory until the age of 14 days.

Results and Discussions

Variation of Physical And Mechanical Properties of The Mortar Plaster Reinforced by Fibers of Length of 10mm with Different Percentages

The results of the variation of physical and mechanical properties of the Mortar plaster reinforced by various dosage of fiber are:

A. The density : From Figure 2, we notice that density decreases slightly with increasing the dosage of fiber, which can be explained by the increase in the volume of void created by the incorporation of fibers where obtaining a less dense plaster mortar. This result is in agreement with the research of DJOUDI [1].

Figure 2: Variation of density of mortar of plaster in function of the percentage by mass of fibers.

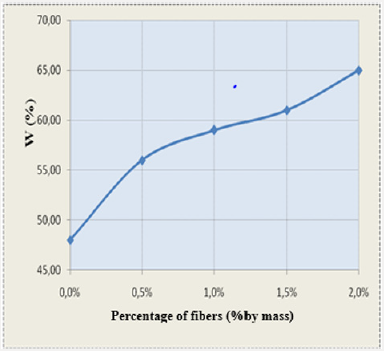

B. The absorption of water: Figure 3 illustrates the evolution of absorption of water for a mortar of plaster reinforced with fibers of a date palm, it is clearly visible that the absorption of water increases according to the increase in the percentage of the fiber plant, this is due to the volume of the high vacuum created by the addition of the fibers and by the nature of the fibers themselves. These results correspond to the results obtained by DJOUDI [1] in his research on concrete plaster reinforced with fiber of date palm, it has been found that incorporation of fibers increases the water absorption of concrete plaster

Figure 3: Variation of water absorption of mortar of plaster in function of the percentage by mass of fibers.

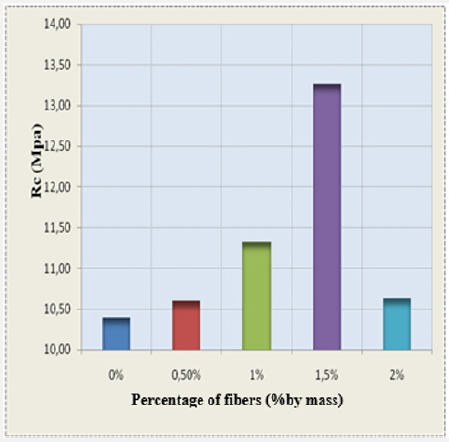

C. Compression strength: According to Figure 4, it can be seen that between 0% and 1% a slight increase in the compressive strength, then 1,5% an acute increase in the compressive strength and after this percentage a Fall in compressive strength. the increase in the compressive strength of mortar, plaster reinforced by fiber of the palm, from the non fibré mortar can be explained that the fibers in the percentage of fat play a role in normal concrete aggregate, and the fall that occurred after this increase, we can judge that the addition of fiber disruption the mortar with mineral skeleton void inside the dough and increasing its porosity, with minimal resistance. These findings are in agreement with most of the research conducted, as Kriker [2], in its research on the concrete reinforced by fibers of palm.

Figure 4: variation of compressive strength of mortar cast according to the mass percentage of fibers.

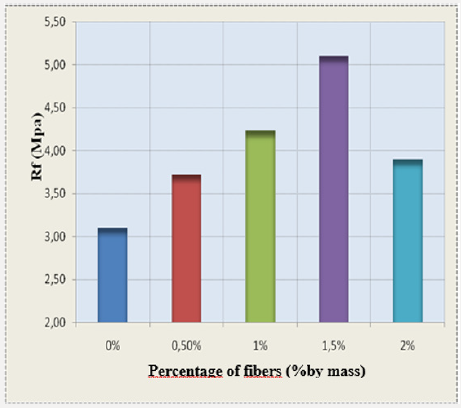

Figure 5: Variation of the flexural strength of plaster mortar as a function of the percentage by mass of fibers.

D. The flexural strength: Figure 5 shows the influence of the length of the fibers on the flexural strength of fiber mortar. First of all, we note clearly that the flexural strength considerable increases with all the lengths of the fibers. A net improvement for the fibers of lengths of 10mm and the resistance reaches the maximum for the lengths of 20mm. After, a decrease in the resistance for lengths 30mm and 40mm, which can be always translates by the loss of manoeuvrability that due to a exercised of fiber and a poor distribution of fibers in the pate increasing porosity and consequently a decrease in the flexural strength. By simulation, we find that the mortar of the plaster has the same properties of the cement mortar. That appears in the research on the cement mortar reinforced by strip of wood. It was found that, for a mortar to 2% had a flexural strength that 3/10 mortar witness that is to say three times more.

E. Recapitulation: The fibers of length 20mm give the best results of resistance to compression and flexion. As these fibers give acceptable results in the density and absorption of water. As for the handling, the mortars reinforced by the fibers of length of 20mm have a good workability and facilitates the implementation.

Read More About Lupine Publishers Journal of Civil Engineering and its Architecture Please Click on Below Link: https://lupinepublishers-civilengineering.blogspot.com/

No comments:

Post a Comment

Note: only a member of this blog may post a comment.