Lupine Publishers- Anthropological and Archaeological Sciences Journal Impact Factor

Abstract

In this article, which we prepared in addition to the works carried

out by tracing a lost cultural heritage, In 1915 Turkish

geography, investigation and photogrammetry study on the narrow-gauge

railroad line built to transport coal from the Black Sea

coast to the Golden Horn will be included. In the study, a CAD model

created by measurements made from old photographs related

to the subject will be used as data in the prototype to be produced by

SLS (Selective Laser Sintering) method. Then, we believe

that the miniature model and production adventure of the Decovil

locomotive, which we have brought to the present with the noncommercial

serial production of the model, will be the means of remembering at

least a cultural heritage that has not reached today.

Introduction

In this part of the study, the research of the historical railway

and its archaeological importance will be shared. In this review,

news published on the internet pages and books and some

collection materials prepared by the researchers were used. The

narrow-gauge railroad line located in the boundaries of Istanbul,

in Kagithane district was founded in 1915. In order to uncover the

lost story of this railway which ended in 1950 with the dismantling

of the rails, a book published named “100 years later on the trail

of a lost railway”. In the study carried out by the Municipality of

Kagithane as a multi-disciplinary team, the team of writers created

an important task in bringing the cultural heritage to the present

day by bringing together the written documents, photographs and

pieces of the railway which have the chance to reach today.

In the studies, many details related to the narrow-gauge

railroad line, which was built for the purpose of transporting coal

from the lignite basin in Agacli (25 km area starting from Kilyos

to the Terkos Lake on the Black Sea coast) to the power plants in

the Golden Horn, have been delivered to our day[1]. If we need

to share some valuable details about the railway: The Kagithane-

Black Sea decovil line, which was effectively used to meet energy

needs during the First World War, was built between 1914 -1916

and is 57 km long (Figure1). The distance between the rails of the

railway is 60cm and this system is called as decovil [2]. The name

dekovil comes from the company founded in 1875 of the surnames

of the French engineer and businessman Paul Decauville who lived

between 1846 -1922 [3].

The period when the line was established, World War I

continues in the region. There is an energy problem in Istanbul due

to the imports of coal stopped from the UK due to the war and the

damage of ships bringing coal from Zonguldak to the region during

the war. The fact that the Canakkale Strait was closed due to the

war made it impossible to import coal through the Mediterranean.

In the Ottoman geography of the period, coal was used as an energy

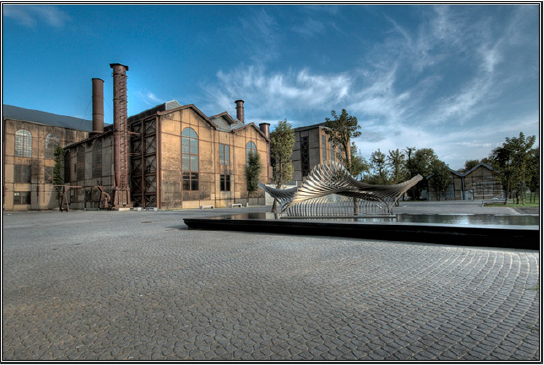

source in ships and power plants rather than domestic fuel. Today

it is a museum building; the building, known as Silahtaraga Power

Plant of the period, meets the electricity needs of Istanbul (Figure2).

With the planned decovil line, it is aimed to evaluate the coal

reserve on the Black Sea coast and to transport it to the Silahtaraga

Power Plant without the need for sea transportation. In this way,

the solution to the energy problem of Istanbul will be produced.

Although the existence of the coal reserves of Agacli, Ciftalan region

on the Black Sea coast has been known since the Byzantine Period,

no studies have been conducted to make the reserve available

for use. After the preliminary investigation, it is determined that

the desired yield can be obtained by mixing the lignite coal in the

region with Zonguldak hard coal, and it is decided to use the coal in

the region and construction of the decovil line is started. The entire

installation works are photographed by Hasan Mukadder Dolen,

the railway regiment officer of the period.

The period when the line was established, World War I

continues in the region. There is an energy problem in Istanbul due

to the imports of coal stopped from the UK due to the war and the

damage of ships bringing coal from Zonguldak to the region during

the war. The fact that the Canakkale Strait was closed due to the

war made it impossible to import coal through the Mediterranean.

In the Ottoman geography of the period, coal was used as an energy

source in ships and power plants rather than domestic fuel. Today

it is a museum building; the building, known as Silahtaraga Power

Plant of the period, meets the electricity needs of Istanbul (Figure2).

With the planned decovil line, it is aimed to evaluate the coal

reserve on the Black Sea coast and to transport it to the Silahtaraga

Power Plant without the need for sea transportation. In this way,

the solution to the energy problem of Istanbul will be produced.

Although the existence of the coal reserves of Agacli, Ciftalan region

on the Black Sea coast has been known since the Byzantine Period,

no studies have been conducted to make the reserve available

for use. After the preliminary investigation, it is determined that

the desired yield can be obtained by mixing the lignite coal in the

region with Zonguldak hard coal, and it is decided to use the coal in

the region and construction of the decovil line is started. The entire

installation works are photographed by Hasan Mukadder Dolen,

the railway regiment officer of the period.

Hasan Mukadder Dolen’s photo collection was left to his

grandson Emre Dolen after his death in 1975. It is known that many

photographs and information about the historical railway have

survived through this channel. Following the first line completed

in 1915, a second line was built in Ciftalan in 1916. Railway rails

and locomotives produced by Germany’s decovil line, with many

stations, vehicles and employees is important in terms of energy

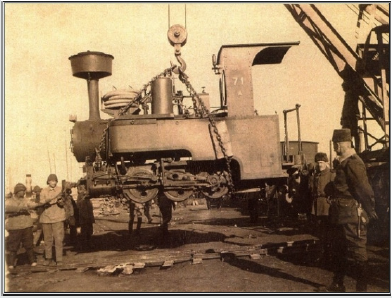

logistics of the period. It is mentioned in the historical documents

that the rails and locomotives transported from Germany to the

Ayestefanos Railway Regiment warehouses in Yesilkoy by the

Danube River were later brought to Eyup, Silahtaraga by ships

(Figure3).

The first line starts from Silahtaraga and reaches Agacli village

after Kagithane stream; the other line runs through the Belgrade

forests to the village of Ciftalan. The light rail line that reached the

Black Sea coast from Kagithane, which is the famous promenade

of the period, undertook an important duty in coal transportation

during the years it was established, but was forgotten by being out

of use in time.

The line was transferred to the Ministry of Commerce in

1922 and to the Ministry of Economy after the proclamation of

the Republic [4]. Although traces of the line disappeared in the

region after 1956, the rails remained largely underground and

in many regions the rails were removed. It is known that one

of the locomotives is currently located in the Celtek coal mine

depot of the Special Provincial Administration of Amasya. In the

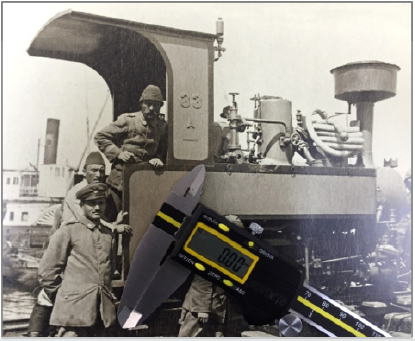

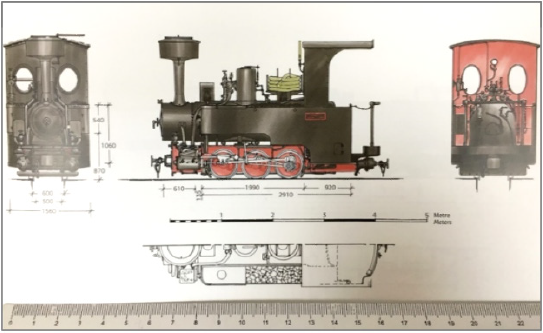

photogrammetry study for the protection of cultural heritage, CAD

model will be created by using original photographs of locomotives

known as Zwilling Heeres Feldbahn (Double Military Decovil)

produced in Munich in 1890 by Krauss Werkshof [1] (Figures 4 &

5). The first prototype of the model produced with SLS (Selective

Laser Sintering) one of today’s 3d print technologies, will be used

for silicon mould technique in mass production.

Literature on Photogrammetry

In this part of the article, the photogrammetry study carried

out with measurements taken from photographs of locomotives

used in historical railway will be shared. In this context, sharing of

literature knowledge about photogrammetry and its usage areas

and then modelling study were included in the study. Visual analysis

techniques are used in many scientific research areas. In the fields

of anthropology and sociology, from the use of photographs of past

periods [7] to airborne imaging technologies[8]; visual analysis

techniques in different scientific fields from ecology, geography to

medical science [9], are basically based on the use of photography

as a source of information. Photographs used as data in the social

field allow interpretations, social-cultural determinations and

visual analysis of the time of the photograph [10]; in technical

fields, it can also be used as a digital data source.

The use of photography for numerical data acquisition will be

explained within the framework of photogrammetry concept. The

word, which consists of a combination of ancient Greek “photos”

(light), “grama” (drawing) and “metron” (measurement), means

measuring with the help of pictures. Photogrammetry, which

is used only in mapping, has been used in different areas in the

following years. Basically, the photographic analysis to determine

the shape, size and position of an object is called photogrammetry

[11]. Photogrammetry is divided into three main sections

(topographic photogrammetry, interpretation photogrammetry,

special purpose photogrammetry) according to the application

areas. Photogrammetry used in the fields of architecture, dentistry

and archaeology is included in this third group [12].

In recent years, many studies have been done to document

the cultural heritage with photogrammetric methods [13],

photogrammetry has been used extensively in histor ical works

documentation and model formation processes [12]. In such

studies, the measurements taken on the photos allow the creation

of the 3-D model of the historical work on the computer with digital

photogrammetric techniques [14]. While the measurement process

is carried out with the points and lines determined by the software,

different methods can be used. In our study, the CAD model, which

is designed with the measurements with calliper and ruler from old

photographs, will be discussed within the scope of special-purpose

photogrammetry.

Modelling Process

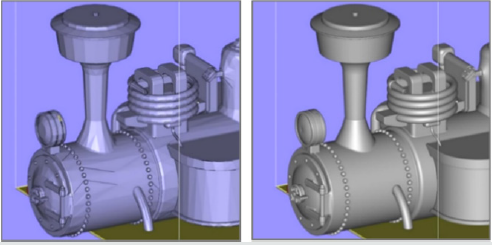

In this part of our study, we will discuss the modelling process

created by taking measurements from the historical photographs

of the railway line locomotive of Kağithane. In the modelling study,

the locomotive CAD model was created in CATIA V5. The modelling;

cabin, nose, mechanical parts and rails, including a total of 4 body

consists of (Figure 7).

Part design tools are used in the modelling. The modelling

of the locomotive as 4 bodies is taken into consideration for the

production criteria for the silicone mould to be needed during

mass production. In this sense, the model has been modelled and

divided into pieces so as to enable post-production assembly. In

the modelling study, first the technical drawings (Figure 6) made

by Alan Prior were used for general information about the model;

in the detail drawings, black and white photographs taken from

different angles were used. After the results of modelling, some

forms are very detailed for the casting process and line softening is

performed according to the model casting process (Figure 7).

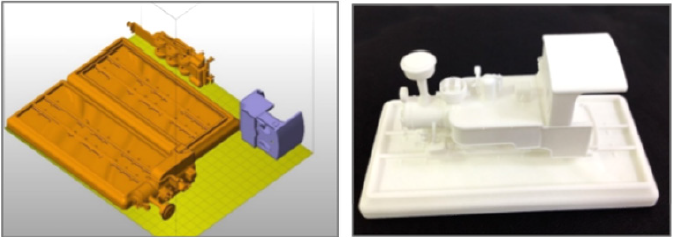

Data Transfer to 3d Printing System After Modelling

(STL File, Quality Problems) STL (Stereolithography) data is

needed for additive manufacturing of the model. The CAD data

generated for this reason is exported in the STL format in the

CATIA software. In this process, STL mesh quality is important

for the surface quality of the model to be produced. The quality

of the prototype to be produced with SLS will affect the quality of

the silicone mould from this prototype. The quality problems in

the STL data are related to the number of mesh on the surface and

the settings of the CATIA display and the necessary arrangement

is made as follows: First, the screen settings are set in the ”tools“ -

”options” – “performance” section in the top menu of the CATIA Part

Design module. In this section, the 3D Accuracy and 2D Accuracy

“fixed” values are revised to “0.01”. The value 0.01 remains constant

until changed again.

The next editing is done in the CATIA STL Rapid Prototyping

module. In the “tesselation” command, with “sag” value, 0.001mm

and “grouped” option preference, the mesh quality of each part is

determined (Figure 8: on the effect of mesh quality adjustment on

surface quality in STL data).

Model Production Process

The technique used in the prototype production is SLS (Selective

Laser Sintering) and the material used is PA 2200 (polyamide). If we

need to give basic information about SLS production system: The

SLS technique is made by sintering micron-size polymer powder

in layers, using laser power. In 1986, Carl Deckard, a student

at the University of Texas, developed this method of powdered

material, which he called PGLSS (Part Generation by Layer wise

Selective Sintering). Later on, this production technique called SLS,

(with the description text: computer-aided laser apparatus which

sequentially sinters a plurality of powder layers to build the desired

part in a layer-by-layer fashion) is patented on October 1986 [15].

The method of SLS production is as follows:

Firstly, files saved in STL format are opened in Netfabb software

and settled in the production area. (Figure5). All parts are sliced at

intervals of 0.1 mm (100 microns) after placement. Then the file

sliced into 100 microns is saved in SLI format. Although there are

60 microns slicing options within the system, 100 microns will be

sufficient for the desired quality. Then the process will continue in

the EOS PSW software. After the material preference and parameter

selection in EOS PSW software, the file will be transferred to the

production bench. The material preference is selected as PA2200

and the layer thickness is 100 microns. The production parameter

is then determined. After the prototype production to be performed

in EOS P110 (Figure 9), silicone moulding will be carried out for

mass production.

The first prototype produced with PA 2200 material, is used to

form the silicone mould. After that, the model which is replicated

in the manufacturer company by casting process from polyester

material is painted with handwork and the final product is obtained

(Figure 10). In classical applications, the silicone mould is taken

from the prototype modelled by the sculptor and polyester casting

process is performed. In the prototype production subject to our

study, the process was completed by using digital technologies and

methods. In the study, modelling was performed in parametric cad

software, enabling the revisions needed in the process to be made

quickly.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.