Lupine Publishers | Journal of Civil Engineering

Abstract

Concrete changes the world. Nanotechnology changes the concrete world. The nano-engineered concrete can be intelligent, strong, durable, easy to fabricate, recyclable and eco-friendly. Its potential benefits include improved infrastructures reliability and longevity, enhanced structural performance and durability, improved safety against natural hazards and vibrations, reduced lifecycle costs in operating and managing infrastructures, and reduced burdens on resources, energy and environment.

Concrete related to sustainable development of human society

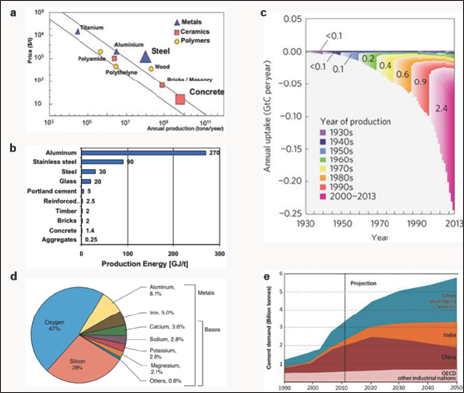

Figure 1: Concrete price and usage; b) Energy consumption for concrete production; c) The cumulative carbon sequestration from 1930 to 2013; d) Elemental composition of the earth; e) Cement demand prediction [1-5].

Concrete's excellent properties and low cost have made it tremendous quantity of concrete (4 billion cubic meters per year) the world's most widely used engineering material (Figure 1a). A has been consumed worldwide for infrastructure construction. China accounts for approximately 60% of the total concrete consumption with the per capita amount of 2 cubic meters. The manufacturing of cement, a key ingredient in concrete, has a significant impact on nature source, energy and environment. In fact, concrete has lower energy consumption and carbon emissions compared to other engineering materials (Figure 1b). According to recent research, as carbon sequestration, concrete can reabsorb a large fraction of CO2 released from cement production. From 1930 to 2013, carbonating concrete absorbed 43% of the cumulative CO2 emissions associated with the high-temperature calcination of carbonate minerals during cement production (Figure 1c). In addition, in terms of resource, it is almost impossible to find an alternative construction material to concrete. This is because O, Si, Al, Fe, Ca, Na, K and Mg comprise 98% of the crustal composition, which are the main components of concrete (Figure 1d). In the long term, on the basis of the urban development of the developing countries and the world's population growth rate, concrete will continue to be massively consumed as construction materials in the whole world. Taking the developing countries such as China and India for example, concrete usage converted by the total amount of cement will nearly double in the coming several decades (Figure 1e). Therefore, concrete is the largest material foundation bearing the civilization in today’s society and even in future society. The production and utilization of concrete are closely related to source, energy and environmental issues, thus having a strong effect on the sustainable development of human society [1-5].

Improving concrete performance to meet the ever-increasing demand for infrastructure construction

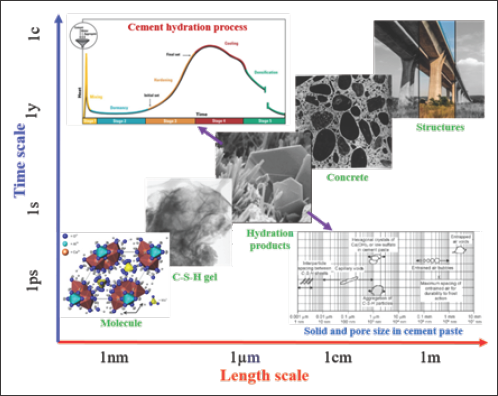

Figure 2: Multi-component, multi-phase and multi-scale nature [4].

Concrete has a multi-component, multi-phase and multi-scale nature and is considered as the most complicated composite while fabricated with the simplest production process (Figure 2). The feature of thermodynamic metastability has an effect on the concrete volume stability. Under deformation, shrinkage and loading, it is vulnerable to interrupt or destroy homophase continuity and heterophase bonding. In addition, concrete is known for its brittleness with low tensile strength, poor deformation performance and high cracking tendency. The presence of cracks tends to weaken the integrity and bearing capacity of structures and severely affect their safety, serviceability and durability, causing potential safety problems on construction. Especially with the trend toward large-scale and complicated infrastructures, extreme service environment, multi-factor coupling and ever-enlarging application field, these problems are becoming more serious and facing with a plenty of new challenges as well. In this case, high- performance and smart/multifunctional concrete becomes the only way to implement the sustainable development of concrete structures. High-performance and smart/multifunctional concrete has excellent mechanical properties, durability and processability needed for structural material. Meanwhile, it also presents selfsensing, self-healing and self-adjusting features. Making use of high- performance and smart/multifunctional concrete can effectively enhance the safety, comfort and durability of infrastructures and maintain a coordinated relationship between infrastructure and environment.

Nanotechnology adding new impetus for developing high-performance and smart/multifunctional concrete

As shown in Figure 2, concrete is a multi-scale complex system. Generally, the normal aggregate in concrete has a particle size ranging from millimeters to centimeters and the particle size of ordinary cement itself is usually 7-200|im. However, cement hydrated phases are primary nano structured materials mainly condensed by C-S-H gel tens of nanometers in size. Therefore, due to its natural attribute, concrete has the properties of nanomaterials. In addition, the scientific community and industry are always spontaneous to manipulate the nano-scale behavior inside concrete using nanotechnology to enhance or modify concrete performance in the process of concrete development, such as nano crystals, mineral admixtures and chemical admixture used for concrete preparation. It should be recognized that nanotechnology in concrete is not a new technique. It is just attributed to the rapid development of nanotechnology in recent two decades improving the understanding of the nano-scale behavior inside concrete and enriching the methods for concrete reinforcement and modification via nanotechnology. In this manner, research in the application of nanotechnology in concrete reaches a very active period.

Awareness of nanotechnology applications in concrete starts at 2001. The addition of nano-SiO2 to concrete was first used for concrete reinforcement. After that, nano-ZrO2, nano-TiO2 and nanocarbon material were applied one after another for the enhancement and modification of concrete. Much work indicated that the big gains in mechanical, durable and functional properties of concrete were achieved by nano nonmetallic oxide and metallic oxide modification. The addition of nano-SiO2 increased the 3d/28d compressive and flexural strengths by 48.1%/48.7% and 45.6%/16.0%, respectively. Meanwhile, the addition of nano-SiO2 can increase the freeze-thaw resistance, chloride penetration and permeability, abrasion resistance and fire resistance of concrete [6]. The fracture toughness of concrete can be enhanced by 400% when nano-ZrO2 is used as fillers [7]. The flexural and compressive strengths of concrete with nano-TiO2 at age of 28 d achieve increases of 87% /6.69 MPa and 12.26%/12.2 MPa with respect to concrete without nano-TiO2, respectively. Nano-TiO2 can also endow concrete with the photocatalytic effect to decompose both organic pollutants and oxides such as NO, NO2 and SO2 [8]. Moreover, extensive research endeavors demonstrated the potential of various nano carbon materials including carbon nanotubes (CNTs), carbon nanofibers (CNFs), and graphene for enhancing/modifying concrete materials [9].

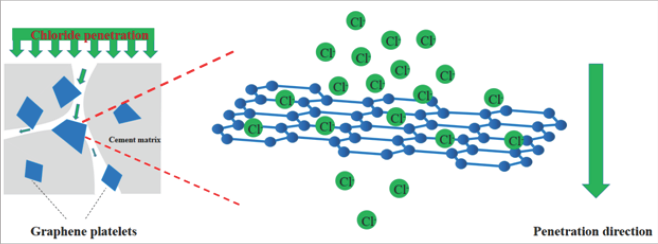

Figure 3: Graphene platelets acting like�filters�for chloride ions [11].

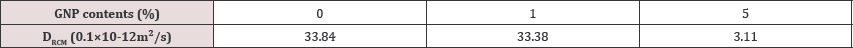

The observed best performance enhancement of concrete with CNTs or CNFs include a relative/absolute enhancements of 79%/74MPa and 64.4%/5.6MPa in compressive and flexural strength [10], a 34.28% increase in tensile strength, a 270% increase in fracture toughness, a 14% increase in fracture energy, an over 600% improvement in Vickers’s hardness at the early ages of hydration, a 2200% increase in deflection, a 130% increase in ductility, an over 430% improvement in resilience and a 227% increase in Young’s modulus. Graphene can improve the tensile, flexural and compressive strength of concrete by 78.6%, 60.7% and 38.9%, respectively. The presence of CNTs obviously enhances the transport property and durability of concrete materials. Graphene significantly improves the moisture transport performance, the acid resistance and the chloride ion penetration resistance (as listed in Table 1 and Figure 3) of the concrete.

Table 1: Chloride migration coefficient of concrete with grapheme.

DRCM: Chloride migration coefficient from non-steady-state migration test

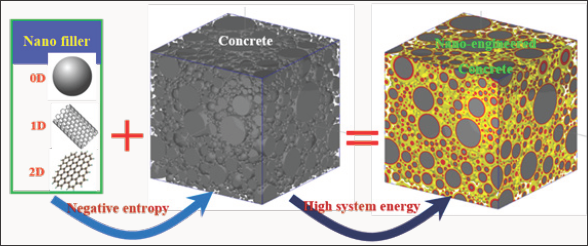

The electrical resistivity reduction extent of concrete materials than that of concrete without CNTs. The damping capacity of with CNTs/nano carbon black composite filler is 99.9%. The concrete with CNTs is 1.6 times than that of concrete without CNTs. thermal conductivity of CNTs concrete composites is 85% greater The addition of CNTs into concrete materials can lead to a 27%decrease in electromagnetic wave reflectivity at a frequency of 2.9 GHz. Additionally, the composites with CNTs, CNFs or graphene feature smart self-sensing (e.g. sensing stress, strain, crack, damage, temperature and smoke), self-heating and steel cathodic protection performances. Nano fillers not only can enhance/modify the also have strong impact on the rheology and workability of fresh concrete [11]. Nano fillers have higher surface energy compared with cement particle. Therefore, as shown in Figure 4, the addition of nano fillers raises the system energy of cementitious composites, thus importing negative entropy to the system of composites.

Figure 4: System of nano-engineered concrete [7].

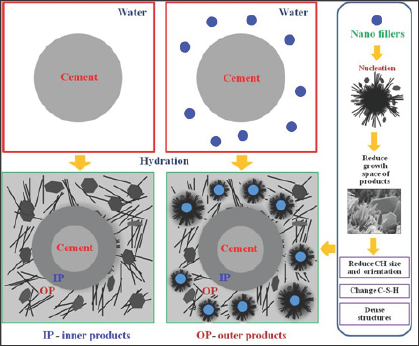

The mechanisms of nano-core effect on the enhancement/ modification are mainly due to two aspects: intrinsically excellent mechanical, electrical, thermal and electromagnetic properties and morphology features (high aspect ratio); and promoting cement hydration, optimizing C-S-H gel structure and forming ultrafine and compact crystals, improving interfacial transition zone and pore structure, controlling nano-scale cracks, autogenous curing, improving early strength and decreasing autogenous shrinkage through nucleating effect (Figure 5).

Figure 5: Schematic diagram of effect of nano fillers on the hydration products growth around cement particles [11].

Conclusion

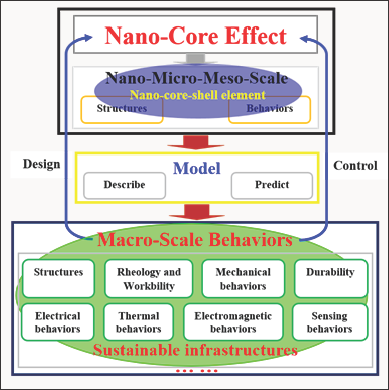

As a new industrial revolution, nanotechnology infiltrating in the field of civil engineering provides new impetus for developing high- performance and smart/multifunctional concrete. To restructure or modify material structural units in nanoscale via interpreting material genetic code and drawing the blueprint of nanoscale properties provides new theory and method to develop high- performance, durable, smart/multifunctional, and environmentally friendly concrete (Figure 6). The utilization of nanotechnology helps promote the understanding of concrete behavior, manipulate and design concrete performance, lower the concrete production and ecological cost, extend the service life of engineering infrastructures and reduce the relative demand of concrete. It is of profound significance to guide the sustainable development and application of concrete material and infrastructures.

Figure 6: Nano-engineered concrete based on nano-core effect.

Acknowledgment

The authors thank the funding supported from the National Science Foundation of China (51578110 and 51428801).

Read More About Lupine Publishers Civil Engineering Journals Please Click on:

https://lupinepublishers-civilengineering.blogspot.com/

No comments:

Post a Comment

Note: only a member of this blog may post a comment.