Lupine Publishers| Trends in Civil Engineering and its Architecture (TCEIA)

Abstract

The physical and rheological properties of asphalt binder have been characterized using the conventional tests; (penetration, ductility, and softening point) and dynamic shear rheometer (DSR). In this study, Calcium Carbonate nanoparticles (CaCO3) and Aluminum hydro oxide (Al2O3) nanoparticles have been added to the base asphalt with a concentration of 3, 5 and 7% by the weight of asphalt. It was found that the addition of CaCO3 and Al2O3 content has a significant effect on the physical properties of the asphalt, as the penetration reduced up to 50% for modified asphalt with CaCO3 and 64% for modified asphalt with Al2O3. The softening point of modified asphalt binders was increased up to 11 and 12% for both modifiers respectively compared with the base asphalt binder. Also, the results showed that the storage stability of modified asphalt binders with CaCO3 and Al2O3 nanoparticles was less than 2.5 °C, which indicates that the asphalt binder and the modifiers having great compatibility. The evaluation of the complex shear modulus of modified asphalt binders shows that the stiffness (G*) was increased with addition increase of both modifiers, and the best performance of asphalt binder was found with the addition of 5% of both nanoparticles. As a result, the use of CaCO3 and Al2O3 nanoparticles can be considered a suitable alternative additive to modify asphalt binder.

Keywords: Calcium carbonate nanoparticles; Dynamic shear rheometer; Modified asphalt binder; Storage stability

Introduction

Asphalt is a dark brown to black cementation material in which the predominating constituents are bitumen, which occurs in nature or is obtained in petroleum processing. Asphalts are viscous liquids or solids essentially consisting of hydrocarbons and their derivatives, which soluble in carbon disulfide [1,2]. They are substantially nonvolatile at ambient temperature and soften gradually when heated. Asphalt has been used for thousands of years, and it is important as a valued engineering material continues to increase. Bitumen has been widely used in the construction of highways and road network, so in that way, asphalt should resist stresses due to traffic loads and low temperature [3]. Due to the limitation of temperature susceptibility, the low, intermediate and high temperatures and temperature performance of the asphalt need to be enhanced. Therefore, modification of base asphalt is necessary to improve the performance of material [4-6]. There are several types of asphalt modifiers, including rubbers, sulfur, polymers, fibers, and nano materials [4,7,8]. Recently, nanotechnology has rapidly been incorporated into the field of asphalt binder with different kinds of nanomaterials being used to modify asphalt and asphalt mixes. It found that nano materials can enhance the performance of asphalt binder and mixture. A study conducted by You et al. Found that nanoclay modified asphalt could reduce the strain failure rate and increase the stiffness (shear complex modulus) of base asphalt [8,9]. Also, using single-wall nano tube materials (SWNT) to modify the asphalt binder, show that the performance grade of the modified asphalt binders increased. Also, the elastic element of complex modulus of the base asphalt was less than the modified asphalts [10]. Based on the study presented by Hui Yao et al. using nano silica to modify asphalt, they found that the addition of nano silica decreases the viscosity rates of unmodified asphalt slightly. Lower and higher viscosity values of asphalt have an influential role in determining the mixing and compaction temperatures. Moreover the addition of nano silica able to reduced and delayed the aging process [11].

Experimental Design

Materials

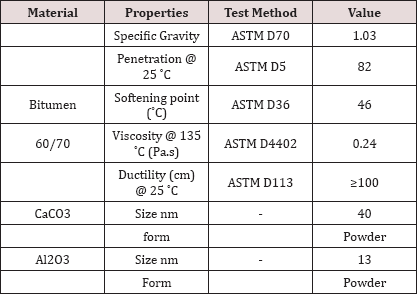

Materials were used to produce some laboratories mixed; Base bitumen binder used in this study was 60/70 penetration grade, while the nanomaterials were aluminum oxide nanoparticles (Al2O3) and Calcium Carbonate nanoparticles (CaCO3) white powder were supplied from China. The physical properties of the base bitumens binder and nanoparticles are shown in (Table 1 & Figure 1).

Figure 1: Modifiers of asphalt binder (a) Al2O3 nano particles (b) CaCO3 nano particles.

Table 1: Physical properties of the base asphalt and nano particles.

Preparation of modified asphalt binders

The base bitumen was heated to 150 °C and stirred for about 10 min, and the temperature was raised up to 170 °C. Three percentages of both modifiers (3,5 and 7% by weight) were added gradually to the base asphalt binder with constant stirring at 170 °C under the high shear mixture speed of 5000rmp for 90min until it achieves a homogenous asphalt binder blend for each percentage respectively.

Testing Procedures

Physical properties

The conventional physical tests, penetration test at 25 °C, Softening point (Ring and Ball) and ductility were conducted according to the American Society for Testing and Materials (ASTM); ASTM D5, ASTM D36, and ASTM D113 respectively.

Storage stability test

The modified asphalt cement storage stability was measured as follows. The samples were poured into an aluminum foil tube; the height of the tube is 16cm in with 3cm in diameter. The foil tubes were closed and stored vertically at a temperature of 163±5 °C in an oven for 48 hours, therefore cooled at room temperature and divided horizontally into three equal parts. The samples taken from the upper and lower sections were used to assess the storage stability of the ASA modified asphalt cement by determining the sections softening points, if the difference between the top and the bottom parts was less than 2.5 °C, then the samples were considered to have excellent high-temperature storage stability. If the softening points differed by more than 2.5 °C, the ASA modified asphalt binder was considered to be unstable [12,13].

Dynamic shear rheometer (DSR)

Dynamic Shear Rheometer (DSR) is used to determine the rheological properties of asphalt binder, including complex shear modulus (G*) and phase angle (5), at low, intermediate and high temperatures. These parameters can be used to describe both viscous and elastic behavior of asphalt. The values of G* and for asphalt binder are highly dependent on the test temperature and frequency of loading. G* is a measure of the total resistance of a material to deformation when exposed to a sinusoidal shear stress load. G* consists of both elastic and viscous components. The 5 is an indicator of the relative amounts of viscous and elastic elements. The DSR used investigates the rheological properties of CaCO3 and Al2O3 nanoparticles modified asphalt binders using a frequency sweep test. The frequency sweep applied was 0.159 to 15 Hz, and the temperatures within range 45+10 to 75 °C. One plate was used in the test, 25 mm diameter spindle with a gap of 1 mm.

Results and Discussion

Physical properties

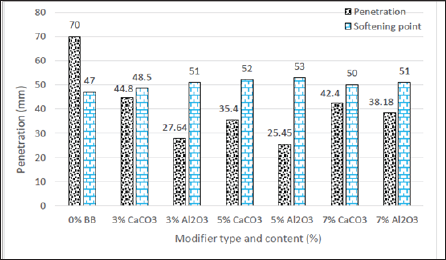

The penetration value was reduced for all modified binders at 25 °C compared with the base asphalt binder. The reduction in the penetration value for modified asphalt binders with CaCO3 was 44.8mm to 3%, 35.4 mm for 5% and 42.4 for 7% respectively. Meanwhile, it was observed that the reduction in modified binders with Al2O3 nanoparticles was. The maximum decrease in the penetration was noted with 5% for both modifiers compared with all asphalt binders. Furthermore, modified asphalt binders give a higher softening temperature compared with base asphalt binder as shown in (Figure 2). Meanwhile, the base asphalt binder has the lowest softening point temperature. The decrease in penetration and an increase in the softening point of modified asphalt binders are a result of the stiffening effect of nanoparticles. In general, the addition of nanoparticles able to enhance the properties of base asphalt up to 5% of modifier, in the meantime concentration of 7% shows different behavior as the penetration increase and softening point decreased. It might be due to agglomeration of nanoparticles during the mixing process [14].

Figure 2: Penetration and softening point of modified asphalt binders.

Storage stability of modified asphalt binders

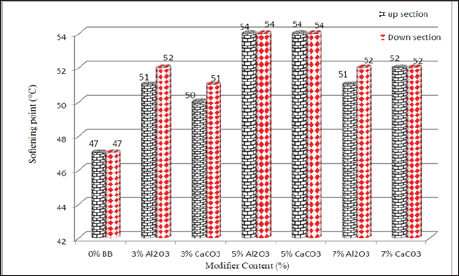

The difference in softening point values between the up and down sections of asphalt binders indicates its storage stability. The less value of the parts, the better storage stability for the modified asphalt binders [15]. (Figure 3) shows the storage stability of the base asphalt binder and modified asphalt binders. It was found that the differences in softening points in modified asphalt binders were 1 °C. Therefore, measuring the softening point of the up and bottom sections of each sample, show that the differences between the top and bottom pass the required value as it is less than 2.5 °C for all binders, this indicates that the nanoparticles modified asphalt binders were quite stable during stored at high temperatures.

Figure 3: Storage stabilities of modified asphalt binders.

The dynamic shear rheometer (DSR)

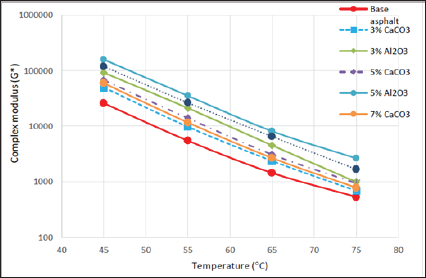

Modify of asphalt binder usually perform in two types of the binders, regarding the compatibility between asphalt and themodifier; the first one, a heterogeneous blend, the asphalt binder, and modifier are incompatible, and they are separated into two phases. The second one is a homogeneous blend, asphalt binder, and the modifier are entirely compatible [16]. The evaluation of rheological properties of modified asphalt binder shows a significant improvement in the performance of asphalt binder.binders whit Al2O3 nano particles have the highest complex shear modulus among the binders, which mean the highest resistance to deformation at elevated temperatures. Wearase, the base asphalt (Figure 4) shows that the addition of modifier increases the stiffness binder has the lowest complex shear modulus.

Figure 4: Isochronal plots of modified asphalt binders.

Conclusion

The evaluation of physical and rheological properties of asphalt binder shows that both modifiers have been successfully improved the physical and rheological properties of modified asphalt binders compared with base asphalt. The penetration decreased and softening point increase, which means the modified bitumen binders become harder compared with base asphalt, and the hardness of binders leads to reduce the temperature susceptibility. Also, it was found that the compatibility between asphalt and nanoparticles is significant, it might due to the uniform dispersion of nanoparticles in the asphalt blends. The result shows that 5% of both modifiers of asphalt binder can be considered as the best performance of asphalt binder.

Read More About Lupine Publishers Trends in Civil Engineering and its Architecture (TCEIA) Please Click on Below Link: https://lupinepublishers-civilengineering.blogspot.com/

No comments:

Post a Comment

Note: only a member of this blog may post a comment.