Lupine Publishers | Modern Approaches on Material Science

Abstract

Titanium alloy (Ti6Al4V) is used for medical prosthetic devices and implants. This study investigated the effect of three types of surface treatments on fatigue and tensile properties of the metal. Representative samples were treated using polishing and chemical passivation using hydrogen peroxide and nitric acid. The surfaces of the treated and untreated samples were observed under an optical microscope and then the samples were subjected to tensile and tensile-fatigue tests using an Instron Servo-Hydraulic machine. The mechanically polished samples had 17% higher fatigue life than untreated samples. In contrast, the hydrogen peroxide and nitric acid treated samples had 5% and 7% lower fatigue life than untreated samples, respectively. Etched grain boundaries were observed on the surface of treated samples. It was concluded that when the samples were subjected to cyclic tensile load, the etched grain boundaries acted as crack initiation points and resulted in low fatigue life. Mechanical polishing on the other hand removed surface damages that could initiate fatigue failure and thus the polished samples had higher fatigue life. Hence, chemical passivation using hydrogen peroxide and nitric acid was unfavorable while polishing was favorable for enhancing fatigue life of the titanium alloy.

Keywords: Fatigue; titanium alloy; surface treatment; biomaterials

Abbreviations: MRI: Magnetic Resonance Imaging; HCF: High Cycle Fatigue; LCF: Low Cycle Fatigue

Introduction

Many metallic biomaterials composed of nontoxic and allergy-free elements have been developed in the recent years. Generally, all metal implants must be non-magnetic and high in density, to be compatible with magnetic resonance imaging (MRI) techniques and visible under X-ray imaging [1]. Titanium and its alloys are commonly used materials for this purpose as they have low specific gravity, excellent corrosion resistance and strength, high biocompatibility, and are non-magnetic. With these advantageous features, titanium is an optimum material for medical prosthetic devices.Approximately one million patients worldwide are treated annually for total replacement of arthritic hips and knee joints, whereas numerous numbers of patients use various devices for bone fracture fixations [1]. Some of the fixers such as screws, plates and intramedullary nails that are commonly made of Ti6Al4V alloy or stainless steel are used for bone fracture treatments [2,3]. Femoral stem hip implant treatments use Ti6Al4V alloy [4].

Most artificial implants are subjected to either static or cyclic loads. For such applications combination of strength and toughness are very important [5]. Metals like titanium alloys have that superior characteristic. Specific requirements of metals depend on the specific implant applications. Stents and stent grafts are implanted to open stenotic blood vessels; therefore, it requires plasticity for expansion and rigidity to maintain dilation. For orthopedic implants such as bone fixations, metals are required to have excellent toughness, elasticity, rigidity, strength, and resistance to fracture [5]. For total joint replacement, metals used should have high wear resistance; so that debris formation from friction can be avoided. Due to the fluctuating nature of the loadings on hips, joints and other movable body parts, fatigue resistance is an important mechanical property that is required for femoral stem and bone fracture fixation applications. Implanted metallic components can experience a spectrum of cyclic loading from normal day-to-day patient activities, thereby an increased chance of high cycle fatigue failure of the components with patient size and level of activity [6]. An implanted metal surface is generally modified by mechanical or chemical methods, or combination of both to improve the biocompatibility and mechanical property [7]. Common mechanical methods are grinding, polishing, machining, blasting and attrition. Chemical treatments that are based on acidic, alkaline, hydrogen peroxide, sol–gel, chemical vapour deposition and biochemical modification are common in modifying a metal surface. Mechanical modification can provide specific surface topographies, clean, or roughen the surface, which can lead to improved adhesion in bonding, as the roughness of the structure can be more favourable for biomineralization due to increased surface area [8]. Chemical methods can improve biocompatibility, bioactivity and bone conductivity, corrosion resistance and removal of contamination [8]. These methods also provide titanium with bioactive surface characteristics.

The addition of 6% aluminum and 4% vanadium to commercially pure titanium results in an alloy having mechanical properties like cold-worked stainless steel (including superior fatigue resistance) yet retaining excellent corrosion resistance. In addition, titanium alloy (Ti6Al4V) is easily weldable and machinable than the pure form. Its principle drawback remains its poor resistance to erosion, making it unacceptable for surface to surface contacts. Titanium based alloys are typically the material of choice for patients having known hypersensitivity reactions to any of the constituents of stainless steel or cobalt-chromium alloys [9].Titanium alloys do not exhibit good seizure toughness. In general, a surface treatment must be applied if the component is subjected to sliding contact. For surface hardening, it is well known that oxygen and nitrogen treatments can be used because they are easily available, inexpensive elements. However, these treatments have a drawback since they cause reduction in fatigue strength [10]. The reason for the decrease in fatigue strength is due to oxygen diffusion into metal surface leading to the development of residual tensile stress on the surface. Shot peening is an effective technique to improve the fatigue strength of oxygen diffusion treated titanium [10].In this study, three types of surface treatments that could easily be applied in a laboratory were investigated for a commonly used medical implant Ti6Al4V. Representative samples were made from commercially available Ti6Al4V rods and their surfaces were treated. Polishing and chemical passivation using hydrogen peroxide and nitric acid surface treatments were employed. The surfaces of the treated and untreated samples were observed under an optical microscope and then the samples were subjected to tensile and tensile-fatigue tests. The effect of the treatments on fatigue and tensile properties was analysed.

Materials and Methods

urface treatment

A mechanical and two chemical surface treatment methods were chosen to modify the surface of commercially available Ti6Al4V alloy rods of 6 mm diameter.

Mechanical surface treatment

A common mechanical surface modification method, polishing was used. An ultrafine abrasive polishing cloth was mounted on buffering wheel of a lathe machine. The lathe machine was set to run at 200 rpm. Each of eight specimens of 150 mm long rod were held firmly against the polishing cloth to polish the specimen.

Hydrogen peroxide treatment

Hydrogen peroxide (H2O2) treatment is a chemical passivation method. Eight clean specimens of 150 mm long titanium alloy rod were immersed in the solution of 30% of hydrogen peroxide. After heating the solution at 95oC with the specimens for 1 hour, the specimens were rinsed with distilled water and ethanol.

Nitric acid treatment

Eight clean specimens of 150 mm long titanium alloy rod were immersed in 30% nitric acid (HNO3) and heated to 60℃ for 30 mins. The specimens were carefully removed and rinsed with distilled water and ethanol.

Visual inspection microscopy

Surface of untreated and treated specimens were examined using a Nikon Epiphot 300 incident light microscope under 100 magnification.

Mechanical tests

Tensile test: Three specimens from each type of untreated, H2O2 and HNO3 surface treated samples were used for tensile test. The test was performed in accordance with the ASTM E8 / E8M - 16a Standard using an Instron servo hydraulic machine 8516. The maximum load, maximum strength and modulus of elasticity were calculated for each specimen.

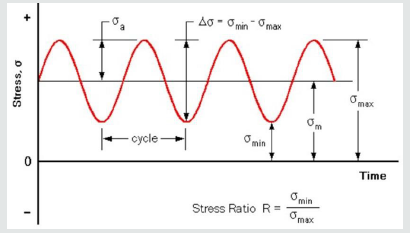

Fatigue Test: Five specimens from each of untreated, H2O2and HNO3 surface treated samples were used for fatigue test using an Instron servo hydraulic machine 8516. A sine curve fatigue cyclic (Figure 1) load was applied for the test. The mean load of the fatigue cycle for all test specimens was maintained at 25 kN which is approximately 80% of the average tensile maximum load that was measured from untreated specimens. The frequency and stress amplitude of the cycle were maintained at 10 Hz and 5 kN, respectively for all tests. The number of cycle and time taken for the failure of each specimen were recorded.

Results and Discussion

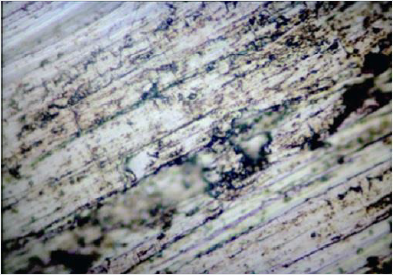

Micrographs of specimen surface

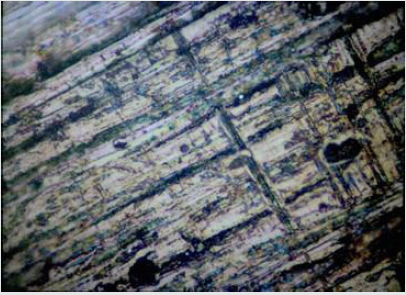

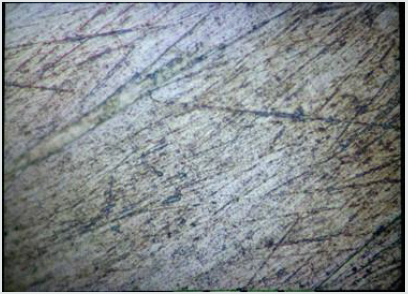

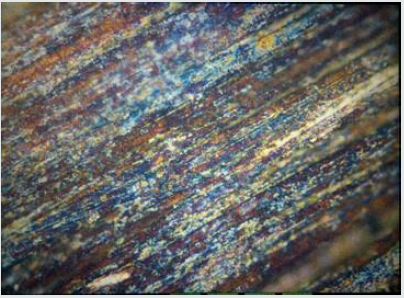

Mechanical polishing provides a smooth surface finish compared to unpolished surfaces. Microscopic image (Figure 2) shows untreated samples had rougher surface with large defects. The surface of polished samples shows apparently smooth surface with very fine scratches as shown in (Figure 3). The H2O2 chemical treatment, referred to chemical passivation method, formed an oxide layer on the surface of the specimens. This treatment is usually conducted to improve corrosion resistance as well as to remove contaminants on the surface of the Titanium alloy. After the hydrogen peroxide treatment, the surface turned into blackish – grey color (Figure 4). It seems a thin film of coating was formed on the surface of the Titanium alloy. The chemical passivation procedure based on nitric acid is used for cleaning and removing contamination, oxides, and small defects. It could dissolve a thin layer of material from the surface and improve the corrosion resistance. Removal of thin layer material could be observed as seen in (Figure 5). The surface defects that existed before the treatment were clearly visible under a microscope as dark patches (Figure 5).

Tensile property

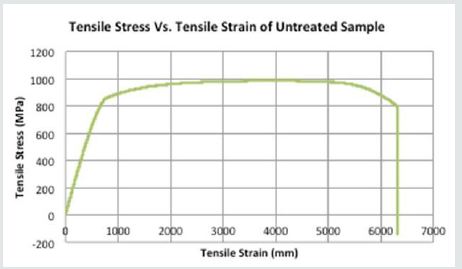

There were no differences in tensile property of untreated and treated specimens observed. A tensile stress-strain graph is shown in (Figure 6) and the tensile test result of treated and untreated specimens is presented in Table 1.

Fatigue property

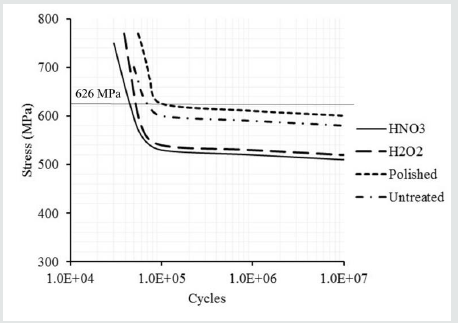

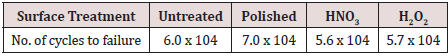

The average number of cycles for failure of untreated, polished, and chemically treated samples are given in Table 2. The fatigue test was designed, and the parameters were set to accelerate the failure for comparative study of different surface treatments.Polished samples had higher number of cycles than untreated and treated samples. H2O2 treated samples took 1,000 more cycles than HNO3treated to fail. However, both chemically treated samples failed earlier than untreated samples. Fatigue failure of a material is usually initiated and propagates from a defect on the surface. When the material is subjected to a cyclic load, cracks at a very small, microscopic scale will begin to form at the stress concentration zone located on the surface of the material [11]. The crack will then propagate and become large with increasing cycle of load and eventually lead to fatigue fracture. The fracture is normally dependent on the size of the defect, and structure of the crack. Untreated (unpolished) samples had surface cracks and failed earlier than compared to polished samples. HNO3 and H2O2treatments that were used for chemical passivation did not improve the fatigue resistance since they neither removed the surface defects nor strengthened the surface.

In general, there are two different types of fatigue: high cycle fatigue (HCF) and low cycle fatigue (LCF). HCF is likely to occur at low stress levels and a high number of cycles to failure. LCF occurs at high stress levels and a low number of cycles to failure. Some materials have a fatigue limit or endurance limit that is the stress level below which the material is unlikely to fail.Five different surface treatments such as annealing, shot-peening, ultrasonic shot-peening, deep-rolling, and laser shock-peening were investigated elsewhere for Ti6Al4V alloy [12]. The fatigue test was performed for each type of treated samples and the stress-number of cycle (S-N) curves were discussed [12]. The ultrasonic shot-peened samples had lowest endurance limit 600 MPa than other samples. The highest endurance limit 700 MPa was observed for laser shock-peened treated samples. In this study, the S-N curves were obtained from curve fitting and extrapolating for the untreated, polished, and HNO3and H2O2treated samples. These curves are illustrated in (Figure 7). For the same mean stress of 625.6 MPa, the polished and chemically treated samples failed at low fatigue cycles when compared to shot-peened, ultrasonic shot-peening, deep-rolled, and laser shock-peened samples. As from the comparison the polished specimen was able to endure 105 cycles whereas the shot peened and deep rolled specimens could endure 106 cycles. However, polished samples had the same endurance limit as shot-peened, ultrasonic shot-peened and deep-rolled samples.The fatigue test was performed in an accelerated condition to complete testing of sample in a day. Using a higher amplitude and frequency would have affected the fatigue strength of the specimens. These factors might cause more surface damages during the test and result in rapid initiation of failure. Hence, determining appropriate test parameters is important for such chemically treated samples of Ti6Al4V alloy.

HNO3 and H2O2 passivation treatments could not remove the surface damage or defects. The HNO3 was also etched the grain boundaries of the titanium alloy (Figure 5). Both chemical treatments were unfavorable to fatigue resistance although they have an advantage in chemical passivation. When comparing the number of cycles achieved by the specimens under different surface treatment, it is determined that the mechanically polished Ti6Al4V alloy had a greater number of cycles and had a longer time to reach failure. The Ti6Al4V alloy that gave the chemical treatments distinctly had a reduced time of failure. The micrographs of the specimens also indicated that when the Ti6Al4V alloy was polished, the weak points on the surface were removed. The surface of the Ti6Al4V alloy appeared to be unblemished by application of the HNO3.

Conclusion

The polishing method did improve the fatigue life of the Ti6Al4V Titanium alloy. The chemical passivation method, even though the advantage of the method is to minimize corrosion, the method was unfavorable to fatigue resistance since the number of cycles and time taken for the specimen to break were lower when compared to the untreated specimens. The combination of polishing method and chemical passivation method on the Titanium alloy might help improve the property of the material such as minimize the corrosion factor and at the same time the polishing might increase the fatigue life of the material. Implants used in Brunei Darussalam are mostly treated through the autoclave process. Polishing of the implants could be introduced in Brunei Darussalam so that the fatigue life of implant can be increased by up to 2-3 years more since the common life span of titanium implant can last for around 10-15 years.

Read more about Lupine Publishers Journal of Modern Approaches on Material Science Click on the below link: https://lupine-publishers-material-science.blogspot.com/

No comments:

Post a Comment

Note: only a member of this blog may post a comment.