Lupine Publishers | LOJ Pharmacology & Clinical Research

Abstract

The effect of inoculating raw milk with Milk Silo Culture (MSC), developed and manufactured by IMAC, Inc. (International Media and Cultures), on retarding the growth of spoilage and pathogenic bacteria, yeast and molds, and viruses through the activation of milk’s natural Lacto-Peroxidase System (LP), has been evaluated. The Milk silo Culture (MSC) has been used successfully for over 30 years, routinely by some dairy food manufacturers around the world. Although the validity and efficacy of MSC has been clearly proven by various leading scientific authorities, yet several of the dairy food manufacturers are skeptical and thus are not taking advantage of the marvelous all-natural biological system to improve the quality, safety, and quantity of the ready to consume dairy food products. The current worldwide Covid-19 pandemic partially or completely changed the thinking and perspective of some consumers regarding the safety of the animal-origin foods they are consuming. Consequently, they are tending towards cerealderived non-dairy products, although milk and dairy products are the best nutritionally balanced foods, with high quality protein and calcium, etc. Since the milk is of animal origin with possible microbial contamination from both animal as well as milk handlers, we felt that it is extremely important to protect the raw milk from pathogenic bacteria and viruses, etc., using all-natural and easyto- implement biological systems, so that the consumers will have utmost confidence to consume such dairy food products.

In addition, we felt that it is equally important that dairy food manufacturers should also benefit from such systems to improve the quantity of dairy food products. Thus, laboratory and commercial research experiments were conducted to study the effect of Milk Silo Culture to accomplish the aforementioned objectives. The result of the study proved that the use of Milk silo culture significantly improved the microbiological safety (significant reduction of pathogenic bacteria and viruses), quality, and quantity (by protecting the microbial degradation of milk protein-casein and fat determined by using particle size analyzer) of the dairy food products, such as widely consumed cheese and fluid milk products, etc., through the activation of milk’s all-natural Lacto- Peroxidase system. Thus, the dairy food industry can go forward safely, without any skepticism, and take advantage of using “Milk Silo culture” to improve the microbiological safety, quality, and quantity of dairy food products to protect human health and to improve consumer confidence.

Keywords: Milk Silo Culture (MSC); Lactoperoxidase (LP) System; Protection of Cheese from Pathogenic Bacteria; Bacteriophage; Extended shelf-life of Fluid Milk; Casein; RNA and DNA Viruses; Increased Cheese Yield and quality

Introduction

Raw milk starts spoiling as soon as it comes out of the cow’s udder due to extraneous microbial contamination. With all the precautions undertaken, it is literally impossible to keep the contaminants away. However, there is an inherent built-in provision in raw milk that can protect it from spoilage. This is called the Lactoperoxidase system. This is also called “LP” system, in short. The “LP” system has three components: Lactoperoxidase enzyme (present in raw milk); Thiocyanate (present in raw milk); Hydrogen Peroxide (not present in raw milk). This system will be activated only when all these three components are present in raw milk. The Lactoperoxidase enzyme acts on thiocyanate in the presence of Hydrogen Peroxide, and converts it to Thiocyanite, which is extremely inhibitory to both the spoilage and pathogenic bacteria, certain yeast and molds and some DNA and RNA viruses (in this connection the SARS-CoV-2 Corona Virus which created covid-19 pandemic is also an RNA virus). The only component which is missing in raw milk to activate the “LP” system is Hydrogen Peroxide.

The question here is how can we induce the production of minute amounts of Hydrogen Peroxide in raw milk to activate the LP system? The specific answer to this puzzle is the use of certain food grade beneficial starter lactic cultures which can produce the molecular Hydrogen Peroxide, when added to raw milk [1]. The addition of food-grade lactic cultures is legal to inoculate the raw milk (while the raw milk is in your possession) without having to declare them. However, the food-grade lactic cultures must be selected based on their intrinsic ability to produce hydrogen peroxide and bacterial-origin (natural) oxidase enzymes. These specialty cultures have been produced by IMAC (International Media and Cultures, A division of the American Dairy and food Consulting Laboratories, Inc.) designated as Milk Silo cultures (MSC) and have been used successfully for the past several years, all over the world, to protect the raw milk in the cheese plants. However, most cheese plants are still reluctant to use them because of a lack of detailed scientific information.

The most often asked question is, how long does it take to activate the LP system in raw milk using the IMAC milk silo culture? The system can be activated in a few hours (4 to 8 hours) in raw milk, in milk silos. Of course, it will be beneficial even if the raw milk is held longer in the silos with the inclusion of Milk silo culture. It has been thoroughly researched by several scientists, who came to a firm conclusion that the activated LP system followed by pasteurization will destroy both the spoilage-type bacteria as well as pathogenic bacteria, Yeast, molds and Viruses, according to Kamau et.al [2,3]. These research findings were science-based and proven through a series of experiments by leading scientists and were also published in the most dependable peer-reviewed scientific journals. I am presenting these references for better clarification to the quality control, Management, and research and development departments, as verification and validity of the statements made and published by the world’s Leading dairy researchers about LP system.

With all this published information, some of the dairy industry personnel are still unwilling to use them and requiring more experimental information to prove its total efficacy. There are two aspects of looking into Milk silo culture (MSC). The first aspect is the effect of activated LP system by MSC to significantly retard the spoilage type Psychrotrophic bacteria (Psychrotrophic - meaning cold loving or loves to grow in refrigerated raw milk) which degrades milk protein casein and milk fat in the shortest time, resulting in the reduction of dairy products yields, especially cheese. In addition, their enzymes are highly heat resistant which survives pasteurization, and start destroying the quality and functionality of cheese and other dairy products. The second aspect is to study the LP system effect on destroying the pathogenic bacteria in raw milk, which I will be addressing in the later part of this article. Earlier, the dairy scientists Lara et.al [4] reported the following regarding the improved cheese yields they have obtained using “LP system” activated raw milk. Of course, which is subsequently pasteurized to make cheese.

According to them the yields of fresh type cheese (measured on a wet or dry bases) of LP treated cow milk were significantly higher than the cheese made from control (no LP activated) milk. They have indicated that a complete transition or recovery of fat from the LP-activated milk into cheese was achieved, while only 85 % of fat was retained in the cheese made from non-LP activated milk or untreated milk. More than all, the quality and microbiological safety of the product was greatly improved due to the retardation of spoilage and harmful micro-organisms. More than 2kg (4.4 lbs.) of extra cheese can be recovered for every 100 kg (220 lbs.) of milk. These research findings were also reported in the most reputable peer- reviewed scientific journal “Milchwissenschaft”. According to other reputable scientists, Earnshaw et.al [5], the cheese made using LP-activated milk did not affect the sensory characters of the cheese and significantly improved the quality and safety of the products. According to them, the activated LP system functions as an effective natural preservation system to increase not only the safety but also quality of the cheese.

The Following Dairy Product (Cheese Etc.) Yield- Reducing and Cheese Quality Degrading Psychrophilic Spoilage Bacteria Encountered in Raw Milk, which are Inhibited by the LP System

The antibacterial activity of the LP system in milk against psychrotrophic spoilage organisms has been widely investigated by Bjorck et. al. [6,7]. Bjorck et. al. demonstrated that LP system was bactericidal (killed the bacteria) against the spoilage bacterial species belonging to pseudomonas and several coliforms such as E. coli. In addition, they have discovered that several milk spoilage type grams -negative rod- shaped bacteria were killed by at least 91%, in a relatively shortest time (4 hr). Furthermore, the activated LP system prevented the growth of the Psychrotrophic bacteria for up to 5 days in raw milk.

The Following Commonly Encountered Pathogenic Bacteria in Raw Milk and in the Subsequent Cheese Products, have been Inhibited by the LP System, According to Several Research Reports Published by the Scientific Authorities, in the Leading Peer- Reviewed Scientific Journals

a) Salmonella: Salmonella typhimurium and several other pathogenic salmonellae causes gastroenteritis in humans, primarily due to ingestion of contaminated foods, including cheese. The activated LP System exerts both bacteriostatic (stops bacterial growth) and bactericidal (kills bacteria) effects against the pathogenic (disease-causing) strains of Salmonella typhimurium in the raw milk [8].

b) Campylobacter jejuni: This is the leading cause of zoonotic infections (animals to humans and vice versa). It mostly infects children under the age of five and immunocompromised individuals. Even in small numbers (500 bacteria) in milk or cheese can cause severe illness in humans by inducing fever, abdominal pain, diarrhea, nausea, vomiting, etc. The LP system exhibits an antibacterial effect on pathogenic Campylobacter species, according to the scientists Beamer et.al. [9].

c) Bacillus cereus: These pathogenic bacteria have been isolated from several samples of raw milk. It causes Bovine Mastitis and thus enters raw milk. It causes food poisoning through the production of toxins. It causes serious clinical conditions including death involving human intestines, lungs, and brain. The good news is that according to the research work of Scientists Tenovue et.al [10], and Zajac et.al. [11], the LP System inhibits Bacillus cereus Pathogenic bacteria found in raw milk.

d) Staphylococcus aureus (Staph): This is a major Causing agent of Bovine mastitis and poses a human health problem since pathogen can enter in to milk from mastitis udders. This organism produces pasteurization resistant toxins (enterotoxins) in raw milk and thus causes severe illness due to food poisoning. Renowned scientists Kamau et.al. [12], have studied, confirmed, and published the data stating that LP System activated in raw milk is both bacteriostatic (stops multiplication) and bactericidal (kills the bacteria) to both the Staphylococcus aureus and Listeria monocytogenes. The other investigators Seifu et.al. [13], also proved LP System activated in goats raw milk inactivated Staph bacterial pathogen both being Bacteriostatic as well as bactericidal.

e) Listeria monocytogenes (Listeria): Listeria monocytogenes is a pathogen of major concern to the dairy industry as food -borne listeriosis due to consumption of milk products, specifically cheese. Listeria infection causes abortion, septicemia, and meningitis in humans. Doyle et.al. [14], confirmed and published the scientific data indicating that the risk of listerioses is amplified by the ability of listeria bacteria to grow at refrigeration temperatures and their relative heat resistance to survive pasteurization temperatures. Several leading scientists Kamau et.al. confirmed that the activated LP system in raw milk (following pasteurization) kills the Listeria bacteria by exhibiting both bactericidal and bacteriostatic effect.

f) Brucella melitensis: This organism causes human Brucellosis. It has been associated predominantly in goat’s milk and goat milks cheeses, which have been attributed to causing Brucellosis. According to scientists Ryser et.al. [15] and Seifu et.al. the activated LP System in raw goat’s milk inhibited or killed the Brucella pathogenic bacteria through exhibiting bactericidal effect.

Antifungal or Anti mold effect of Lactoperoxidase system activated in raw milk to inhibit milk associated molds and some yeasts

Yeast and molds cannot be avoided in raw milk due to extraneous contamination. Although their vegetative cells can be inactivated by pasteurization of milk, their harmful toxins (Aflatoxin) cannot be destroyed with mere thermal heat treatment. In addition, some of the mold spores may survive pasteurization. Jacob et.al. [16], have published data showing that activated Lactoperoxidase system inhibited the growth of several mold species in raw milk. Doyle and Marth [17] have demonstrated that mold-produced toxic aflatoxin can be degraded or destroyed by the Lactoperoxidase system. This is a significant finding.

Antiviral effect of the Lactoperoxidase system on RNA viruses (SARS-CoV-2 virus causing COVID-19)

The latest SARS-CoV-2 virus causing Covid-19 pandemic has brought significant awareness to the public around the world, due to its devastating effect on humanity and economy. Many people in various sections are questioning even the safety of food products and the food industry practices regarding the total assurance of not having any viral contaminants, in ready to consume foods. Wherever there is human involvement, it is hard to eliminate the presence and prevalence of pathogenic viruses. It has been proven and reported by Scientists Belding et.al. [18], and Yamaguchi et.al. [19], that Lactoperoxidase system (LP System) can kill the most resistant Polio and HIV-1 viruses. As we all know, Polio and HIV-1 viruses are RNA viruses. In addition, the notable human diseases caused by RNA viruses include the common cold, influenza, SARS, MERS, Covid 19, Dengue virus, Hepatitis-C, Hepatitis -E, West Nile Fever, Ebola, Rabies, Polio, Mumps, and Measles etc.

Since it has been proven that activated Lactoperoxidase system is viricidal to several hard to kill RNA viruses, it can be hypothesized that the raw milk’s activated LP system may also have effect on inhibiting several RNA viruses including SARS- CoV-2, which caused Covid -19 pandemic. In fact, now it is proven by Cegolon et.al. [20], in 2021 that thiocyanite of LP system even at a micromolar concentration can destroy or be viricidal to the SARS-CoV-2 virus through irreversible oxidative damage of the lipid components of the viral envelop of the nucleoproteins. Although it has been proven that the LP system inhibits the pathogenic bacteria, yeast and molds, viruses, and the spoilage organisms in raw milk, according to Reddy [21], yet some of the dairy industry personnel are requesting more concrete data and simplified approach to implement such systems in their manufacturing facilities. Thus, the following research experiments were conducted and reported in this article.

Materials and Methods

The following research experiments were conducted to study the effect of Milk Silo cultures (MSC) inoculation into raw milk, and their effect of inhibiting DNA viruses (Bacteriophages), spoilage type bacteria, reducing the breakdown of milk nutrients, and finally to improve the quantity and quality and safety of the dairy products.

a) The antiviral effect of the MSC activated Lacto-peroxidase system on DNA virus in raw milk.

b) Antibacterial effect of Milk silo culture (MSC) on retarding spoilage type bacteria in the raw milk and after pasteurization, to extend the shelf-life of grade-A fluid milk.

c) Milk protein (casein) and fat protecting effect of MSC to improve the quality and quantity of these essential nutrients, determined using Particle Size Analyzer.

d) Effect of MSC on improving the dairy product yield, safety from pathogenic bacteria, yeast and molds, and quality proven through controlled laboratories cheese yield experiments.

Experiment 1: Antiviral Effect of Lactoperoxidase System on DNA Virus (Bacteriophage)

The grade A raw milk was inoculated with DNA virus Streptococcus thermophilus bacteriophage to arrive at 120 x 106 (120 million) Phage particles/ml. The milk silo culture (MSC) supplied by IMAC (International Media and Cultures) is a frozen can comprising of food grade thermophilic and mesophilic lactic acid producing bacteria along with their growth-end products (immunomodulins). These immunomodulins include bacteriocins, antibacterial therapeutic bio-peptides, non-specific inhibitory compounds, organic acids and traces of preformed molecular hydrogen peroxide and enzymes. The thawed Milk Silo culture was inoculated into raw milk using the equivalent amount of 2 cans (260 ml.) per 100,000 lbs. of milk. The frozen Milk Silo Cultures were thawed fully and then the liquid culture was added into the milk silo. The inoculated milk was incubated at the refrigeration temperatures (comparable to milk silos) for 8 hours. Then the milk was pasteurized at 161 F. for 15 sec (commercial HTST pasteurization temperature). The bacteriophage counts were determined using plaque assay before and after pasteurization using the specific bacterial host (Streptococcus thermophilus) of the bacteriophage included in this study. The phage inoculated raw milk without the addition of milk silo culture served as control. The results are presented in the results and discussion section.

Experiment 2: The Effect of Milk Silo Culture Activated LP System on Reducing the Spoilage Type Bacteria Present in Raw Milk, and after Pasteurization to Extend the Shelf Life of Grade A Fluid Milk

Grade A raw milk obtained freshly from farm was divided into two fractions. One is inoculated with Milk Silo Culture (MSC), the other fraction without MSC was treated as control. The Milk Silo Culture inoculation was comparable to using 260 ml of culture for 100,000 lbs. of milk. Both the fractions were pasteurized at 161F for 15 seconds. Both the pasteurized samples were plated to determine the total bacterial count using SPC (standard plate count). Also, the samples were plated to determine the psychrotrophic bacterial counts as well as the coliform counts. The samples were stored in the refrigerator for an extended length of 30 days. The samples were analyzed organoleptically for flavor and taste at intervals of 15, 20,25, and 30 days, during the storage. The bacterial counts were determined also at the end of the storage at the refrigeration temperature.

Experiment 3: The Effect of Milk Silo Cultures Inoculation in Refrigerated Commercial Raw Milk on Protecting the Microbial Degradation of Milk Protein (Casein) and Milk Fat in 24 Hours determined using a Particle Size Analyzer

Normal raw milk on average will have approximately 3.5 % protein and 3.2% fat. After milking, the pooled milk is placed in a refrigerated tank at the farm for a period of few hours to a day or two. Then the milk is picked up by the trucker going from farm to farm. Such comingled milk is being transported to the cheese or any dairy product manufacturing plant. The raw milk is then pumped from truck into large, refrigerated milk silo at the processing plant. The raw milk will be in silos for at least 8-12 hours to one or two days, depending on the day of the manufacturing. All along the psychrotrophic bacteria present in raw milk will be growing, since they can grow and multiply in the refrigerated cold raw milk. Their maximum deleterious effect is towards the end of their journey. These psychrotrophic organisms produce heat resistant proteolytic (protein breaking) and lipolytic (fat breaking) enzymes, which will degrade milk proteins and fats in raw milk during storage.

Even if psychrotrophic bacteria consume 0.05% protein and 0.05% fat, it will reflect in a great loss to the cheese manufacturer due to loss of significant quantity of cheese, especially considering 95% of the cost of the cheese is attributed to milk. The end products of the growth and the enzymes elaborated by the Psychrotrophic bacteria, will significantly alter the quality of the finished dairy product. Similar thing will happen even with the pathogenic bacteria as well as Yeast and molds in the raw milk, since presence, absence and concentration of these organisms is a classical hit and miss proposition. None of the investigators earlier has studied the exact loss of the protein and fat during storage for up to 24 hours at the cheese plant or any dairy product producing facility at the minute level. Thus, we undertook a study to determine the exact loss of the protein and fat in raw milk due to growth of psychotropic bacteria, by using the particle size analyzer, which will determine the degradation of solids accurately.

The physical chemistry and mechanism of how the Particle Size analyzer work is as follows: The principle behind the Melvern particle Analyzer, to determine the degree of breakdown of milk protein and milk fat in milk is as follows: laser diffraction measures particle size distribution by measuring the angular variation in intensity of light scattered as a laser beam passes through a dispersed particulate sample. Large particles scatter light at small angles relative to the laser beam and small particles scatter light at large angles. The angular scattering intensity data is then analyzed to calculate the size of the particles responsible for the scattering pattern, using the Mie theory of light scattering. The particle size is reported as a volume equivalent sphere diameter. This research was conducted at the factory level in a plant processing over one million pounds of milk a day making Mozzarella cheese in southern Wales, U.K. The holding capacity of each milk silo is 300,000lbs.

We have elected to use 2 milk Silos and inoculated the milk in silo with 6 cans of Milk Silo Cultures. One can contain 130 grams of milk silo culture per 50,000 lbs. of milk). The other silo was not inoculated with the Milk Silo Culture served as control. Milk at zero time (prior inoculation of the milk silo culture) served as control. The raw milk after 24 hours, with and without inoculation of MSC served as positive and negative controls. All the samples were analyzed for the degradation of solids by using the particle size analyzer and for the protein and fat breakdown using standard lab tests. The cheese made with such milk was also analyzed for the microbiological as well as for the quality and quantity of the cheese. The results of this experiment are presented in the results and discussion section. The theoretical cheese yields were determined using modified Cornell Van slyke Formula, developed for the Mozzarella cheese.

Experiment 4: The Controlled Laboratory Experiments Conducted to Check the Effect of Milk Silo Culture Inoculation into Raw Milk on Improving the Safety (Freedom from Spoilage and Pathogenic Bacteria), Quantity (Yields) and Quality of the Dairy Products-Cheese and the Whey.

To study the effect of Milk Silo Culture on the retardation of casein and fat breakdown in cheese milk and thus improve the cheese yield, quality and safety of the dairy product, the following experiments were designed. Grade A raw milk (3.5% milk fat) was divided into eight, 200 ml. fractions. Four of the 200 ml. fractions were not inoculated with Milk Silo Culture and were considered as controls. The other remaining four, 200 ml. fractions were inoculated with amount comparable to inoculation of two 130 ml. cans of Milk Silo Culture /100,000 lbs. of raw milk. The treated and untreated milk were stored at the refrigeration temperature for 24, 48, 72, and 96 hours. The first set was designated as 24 hours held raw milk in Milk Silo. The milk was heated to 161 F for 15 seconds. and then cooled to 98F.

Both treated and untreated samples were inoculated with 1.0% milk grown streptococcus thermophilus bacterial culture and incubated (ripened) for 30 minutes. At the end of ripening, calf rennet was added to the ripened milk, at the comparable rate of one ounce per 1000 lbs. of milk and held for 30 minutes until it is set. The coagulum was cut, healed for 5 min., cooked to 104 F., and the whey was drained. The curd was pressed overnight, and the run-off whey was collected. The curd was weighed, and the moisture and fat were determined. Whey was also weighed, and the whey solids and fat were determined. Similar cheese making procedure was followed with all the other variables (treated and untreated samples held for 48, 72, and 96 hours). In addition, the cheese samples were plated to check for the presence of pathogenic bacteria. The cheese samples were analyzed for the flavor, body, and texture by using the expert panels. The results are presented in the results and discussion section (Tables 1-3).

Results and Discussions

Results of Experiment 1

The milk silo culture added raw milk, after pasteurization has exhibited a drop of two logs of the count. Initial phage count was 120 x 106/ml, and phage count after pasteurization was 80 x 104 /ml. Whereas the control did not exhibit any drop in the phage numbers. The phages which infect the thermophilic bacteria are more resistant to pasteurization temperature than the mesophilic lactic cultures. Thus, phages infecting mesophilic lactic cultures must be more sensitive to Lactoperoxidase activated system in raw milk. Earlier, it was also proven that SARS-CoV-2 corona virus gets inactivated with activated LP system. It has been clearly pointed out in the literature that LP system also inhibits or can destroy some other DNA viruses. However, there are no reports so far in the literature regarding the effect of Milk Silo Culture activated LP System on retarding the dairy starter culture lysing DNA Virus.

Since dairy associated bacteriophage which can destroy or lyse the mesophilic and thermophilic starter cultures are DNA viruses (with a rigid outer protein envelop), this investigation was undertaken to study the effect of LP system intermediates in raw milk followed by pasteurization, to inactivate the phage in raw milk. Raw milk is the biggest source of bacteriophage in the dairy and cheese industry. In addition to these laboratory studies, the phage protecting effect of Milk Silo Cultures were monitored in several commercial factories. So far, none of the plants which have been using the milk silo cultures routinely in raw milk, have encountered any serious phage problems.

Of course, they were also following strict sanitation (like anybody else) procedures, culture rotations, and specifically several of them use bulk starters. In addition, none of them had any pathogen problems either, whatsoever. Since 70 % of the Lactoperoxidase enzyme and natural thiocyanate present in raw milk survives pasteurization, the use of bulk starters with molecular hydrogen peroxide produced by starter cultures, further activates the LP System in the pasteurized milk, in the cheese vat, and thus retards or kills any other post pasteurization contaminated yeast and molds, and pathogenic bacteria and virus etc. Thus, combination of both inoculation of milk silo cultures into raw milk and use of bulk starters grown in phage resistant media assures good cheese yields, quality and freedom from pathogenic bacteria, some molds and yeasts, and viruses in the finished cheese and whey products.

Results of Experiment 2

The Total bacterial counts, immediately after pasteurization were 5000 /ml in the LP activated milk, in comparison to 18,000/ ml in the non-LP activated milk. The psychrotrophic bacterial counts were less than 10/ml for LP activated milk, whereas non- LP activated milk were 20/ml. Both the samples were negative for coliforms. The organoleptic tests revealed that the pasteurized non-LP activated milk did not have any fresh milk flavor on fifteenday storage in the refrigerator, and progressively exhibited slight off flavor on twentieth day, and a distinct spoiled flavor on 25th day. The psychrotrophic bacterial counts obtained on twenty-fifth day far exceeded one million bacteria /ml. Whereas the LP activated milk did not exhibit any off flavor even at 30-day storage, according to the trained panelist, both in terms of flavor and taste. The LP activated milk had less than 100 psychrotrophic bacteria (even the colonies were small) and SPC count was 17,000/ml. Thus, the LP activated milk passed the organoleptic tests even after 30- day storage, and perhaps it could have gone longer also without spoilage.

These results were highly reproducible. This experiment clearly proved that Milk Silo Culture activated pasteurized fluid milk significantly reduced the psychrotrophic bacteria and their heat resistant proteolytic and Lipolytic enzymes, judged based on organoleptic tests. Our experiments in the laboratory proved that LP activated raw milk using Milk Silo Culture, after pasteurization, can be safe to give sell by date 30 days, stored at 4C, as opposed to 21 to 24 days of the non-LP treated milk. This 6 day longer safe storage extension will be good for both the manufacturer, retail, and the consumer. Of course, 30 days sell by date can only be given on the basis that the container is not opened, and the milk is stored at proper refrigeration temperature. It has tremendous significance because the spoilage of milk associated may also have some nonbeneficial pathogenic type bacteria etc., may also harbor some of the heat resistant or post pasteurization contaminated bacteria. Milk Silo Culture addition to raw milk, prior to pasteurization assures the microbiological safety of the fluid milk.

Results of Experiment 3

This is the first of its kind of experiment conducted to determine the degree of breakdown of essential milk solids, casein, and fat, by the psychrotrophic bacteria in less than 24 hours of storage of raw milk in the refrigerated silos. The broken-down fractions of casein and fat will end up in whey and not in cheese matrix. In addition, the enzymes produced by the psychrotrophic bacteria (Proteolytic as well as lipolytic enzymes) are thermostable and resist the normal pasteurization temperature and thus continue their deleterious effect into the stored cheese and also into the subsequent whey products. Using this approach of using particle Size Analyzer and the quantitative analytical techniques we have quantified and determined that the use of IMAC’s Milk silo Cultures protected the loss of casein by 0.08% and loss of fat by 0.06% due to the growth or effect of psychrotrophs (cold loving bacteria naturally present in the raw milk) during less than or equal to 24-hour storage of raw milk in milk silos at the dairy plant (cheese plant).

Milk Silo Culture Laser Diffraction Data

Particle sizing is a unique way to study the effects of introduced variables into preexisting systems. IMAC Inc., in conjunction with Dansco Dairies Ltd. (UK) and Malvern Instruments (UK), and researchers from Oxford University, England, conducted a series of experiments to quantitatively determine the effectiveness of MILK SILO CULTURE in protecting the quality and quantity of the essential milk nutrients namely casein (milk protein) and fat. Milk contains a standard array of particles that have a definite size. Fat, protein, lactose, vitamins, and minerals can all be allocated a size range and can be measured by laser diffraction particle analysis. If degeneration of the milk components by psychrotrophic bacteria occurs, then the existing components in milk will be altered to different size particles within the milk.

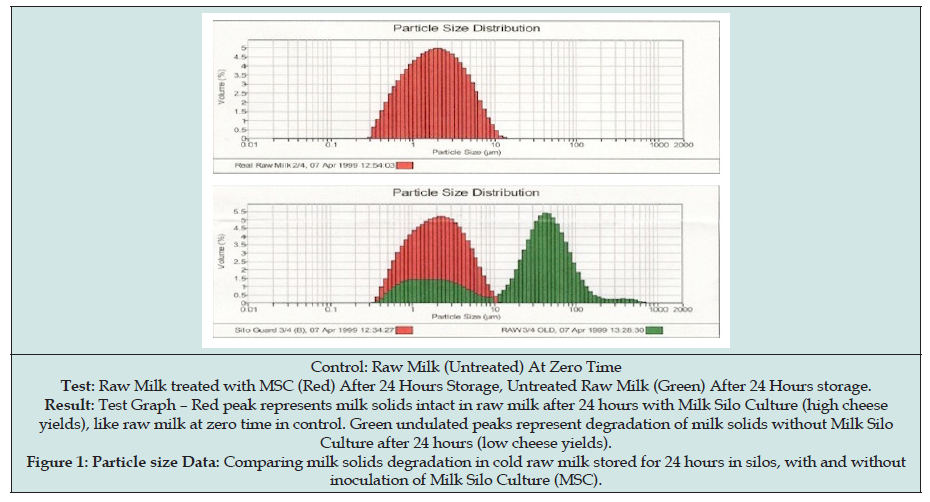

Figure 1: Particle size Data: Comparing milk solids degradation in cold raw milk stored for 24 hours in silos, with and without inoculation of Milk Silo Culture (MSC).

In Figure 1, the first graph demonstrates clean, fresh, refrigerated raw milk from the silo at zero time. This sample does not contain MILK SILO CULTURE and is used as the CONTROL. The CONTROL indicates that no breakdown of milk components has occurred. The second graph in Figure 1 demonstrates the test portion of the experiment, where MILK SILO CULTURE was added in silo to the fresh raw milk in one sample, and another CONTROL sample was left untreated in the silo. Both the treated and untreated milk were held at refrigeration temperatures in the silo for 24 hours. The results are clearly evident from the graphs in Figure 1. The region in RED is the raw milk treated with MILK SILO CULTURE - it demonstrates little to no change from the aforementioned CONTROL sample - this means little to no breakdown of components within the MILK SILO CULTURE treated sample has occurred in 24 hours.

The TEST sample, which is the GREEN region on the graph, shows what happens to milk that is not treated with MILK SILO CULTURE- the particles have altered significantly, which is evident from the graphs in Figure 1. Even in the harshest of conditions, IMAC MILK SILO CULTURE protects the valuable components of milk from spoilage, resulting in improving quality, safety, and savings in terms of milk performance and losses, and even energy costs. More than all, the dairy product made with such milk has more nutritive value and is safer for consumption. It has been proven earlier that several pathogenic bacteria can be inactivated by the activated LP system in raw milk due to Milk Silo cultures. It is a win-win situation in that both dairy products manufacturers and the consumers gets benefited. Because of this, some of the Dairy product manufacturing facilities instituted the use of Milk silo cultures into raw milk in milk silos as a part of Total Quality management (TQM). Contrary to peoples thinking the maximum amount of psychrotrophic bacterial growth occurs at the end of storage of milk in the milk silos at the factory level.

Such an infinitesimal amount of casein and fat protected by the use of milk silo cultures, will save, or improve the net bottom line of the cheese plant by $1,500,000 per year, in a plant processing one million pounds of milk per day, 6 days a week. As an example, plugging the above data into theoretical yield model using the Van Slyke formula, it has been determined that cheese yield can be improved by 3.125 percent over the standard yield, (Control of mozzarella cheese yield without the use of MSC is 9.3%, whereas the yield due to use of Milk Silo cultures (MSC) is 9.6%), keeping all other factors such as moisture etc. constant. This has been confirmed further by considering the actual yield. Although there was variation between theoretical yield and the actual yield with the control milk. The variation is minimal with the milk treated with Milk Silo culture and the yields and quality are significantly superior in comparison to the control. Accordingly, you can calculate the net profit to your cheese plant depending on the volume of milk processed per day, and the number of working days in a week. None of the pathogens were detected in the dairy product (cheese).

Results of Experiment 4

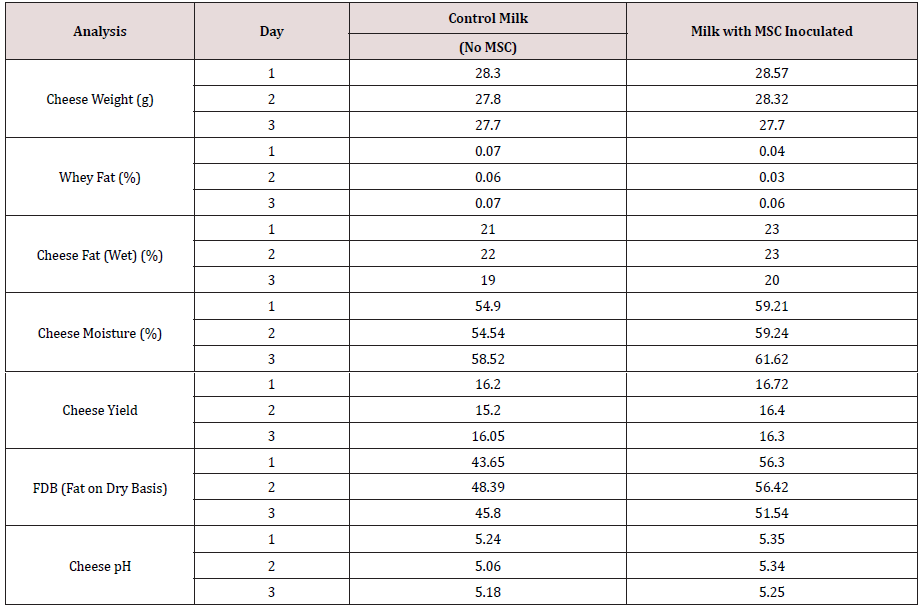

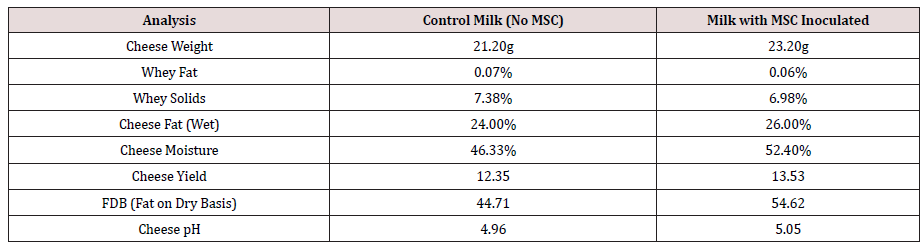

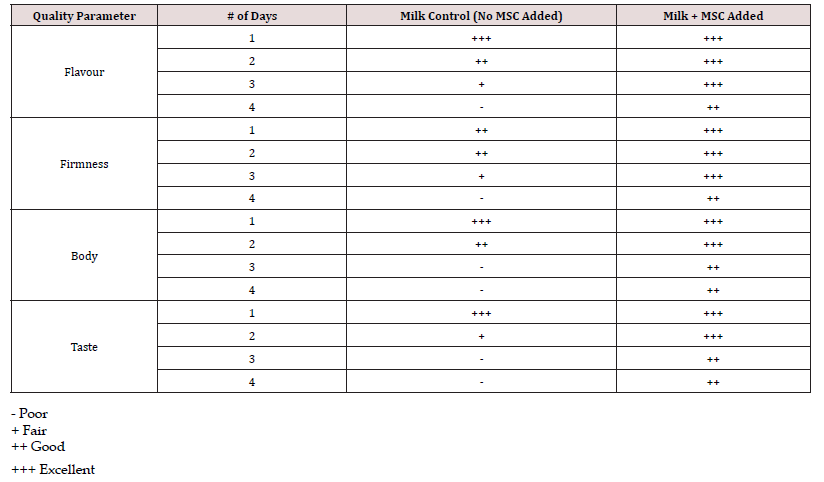

The results proved that the treated milk greatly improved the yield (Tables 1&3) and the quality of cheese in terms of texture and flavor (Table 2). On average the cheese yield improved by 0.5% compared to the untreated milk. The cheese curd or the cheese that was made on Friday on the last set of treated milk was pressed over the weekend. The results are presented in Table 3. The results clearly indicated that Milk silo culture greatly improved the yields and the quality of cheese. The treated raw milk held at 4 C for 4 days also improved the yield by 1.18 % compared to untreated milk. The quality of whey was excellent in terms of smell and taste, according to the Judges. Such whey was free from pathogenic bacteria and upon drying had excellent color (not an objectionable dark color). The safety of whey products is extremely important because of their wide usage as sweet whey, Whey protein concentrates, whey protein isolates, in the baby food formulas, and in the nutritional products and formulations especially for the athletes and the geriatric population to control or treat Sarco- Penia (muscle loss).

Table 1: The Effect of Milk Silo Culture (MSC) on Raw Milk Held at refrigeration temperature for up to 4 Days on Cheese Yield and Composition of Whey.

Table 2: The Effect of Milk Silo Culture (MSC) in Milk After 4 Days storage at refrigeration temperature on cheese yields and composition of whey.

Table 3: The Effect of Milk Silo Culture (MSC), (Milk Held at refrigeration temperature for up to 4 Days) on the microbiologically altered rheological properties of Cheese.

Several Experiments conducted on a large scale in commercial cheese plants processing over a million pounds of milk per day also revealed comparable results. The commercial experiments with the use of Milk Silo Cultures were also conducted in various Dairy plants (cheese) located in mid-west, east coast and west coast of the U.S. and also cheese plants located in Wales, Southern and Northern Ireland, Scotland, South America, and Southeast Asia etc. Irrespective of the geographic region, the use of Milk Silo Cultures improved the quality, quantity, and safety of dairy products. None of the dairy products (cheese) produced with milk Silo Cultures had any problems with Bacteriophage, pathogenic bacteria, such as Salmonella, Listeria, Staphylococci, Enteropathogenic E. Coli, campylobacter, and Yersinia etc.

In this connection, it is worthwhile to mention that there are no Government regulations to check for the presence of pathogenic bacteria in raw milk. It is taken for granted that the legal pasteurization of 161 F for 15 secs. should eliminate all the pathogenic bacteria. It is not true anymore because it has been found that certain pathogenic strains of Listeria monocytogenes, can survive pasteurization by being embedded in the leucocytes, Reddy [21]. The effect of Global warming on microbial mutation cannot be ignored. Thus, we can no longer rely on past research results. In addition, unless the LP system is activated, the postpasteurization contaminated pathogenic bacteria or the pathogens which survived the pasteurization cannot be curtailed. Thus, it is highly recommended to use Milk Silo Cultures in raw milk, to produce superior quality dairy products with better functionality and more than all the safety of the products in terms of free from both spoilage and pathogenic bacteria, to protect consumers worldwide.

Conclusion

The laboratory experiments and commercial successful trials proved beyond doubt that the milk’s natural Lactoperoxidase system (LP System) activated through the use of Milk Silo Cultures, upon pasteurization distinctly reduced the spoilage type and pathogenic bacteria, and the breakdown of milk solids (Casein and Fat). In addition, it was proven using the particle Size Analyzer that in 24 hours’ time of retention of raw milk in silos at the dairy products manufacturing facilities, the psychrotrophic bacteria reduced casein by 0.08% and milk fat by 0.06%. Use of Milk Silo cultures prevented the degradation of both casein as well as milk fat. Milk Silo Cultures, by activating the LP System followed by Pasteurization exhibited the inhibition of DNA Bacteriophage active against most widely used starter culture Streptococcus thermophilus. It has a great significance in that the protection of the starter cultures from viral infection assures the improved quality in terms of reduction of both spoilage bacteria, as well as the pathogenic bacteria in the dairy products, such as cheese, yogurt, and other fermented products.

Experiments conducted on the prevention of spoilage of the pasteurized milk using Milk Silo Cultures proved beyond doubt that the shelf-life and the safety of the fluid milk can be significantly improved, beyond the sell by date. It has a significant effect since milk can be stored for a longer period to eliminate dumping, which can be otherwise used to feed people. Furthermore, such dumping will induce pollution problems resulting in environmental issues. The experiments conducted on improving the dairy product (cheese) yields and quality with the introduction of Milk Silo Cultures into raw milk were phenomenally successful. Not only the cheese yields increased, but also the rheological properties and more than all complete eradication of pathogenic bacteria and viruses were observed. Once again, it is extremely important because the increased amount of food will reduce the cost of production, and also improve the safety of the products and improve the confidence of the consumers. Considering the positive results of this laborious research, the dairy industry worldwide can implement the usage of the milk silo cultures into raw milk to activate the raw milk natural protective Lactoperoxidase system to improve the quality, quantity, shelf-life, and safety of the dairy products.

Acknowledgement

I am extremely thankful to Mr. V. R. Mantha, director of Quality Control and Research and Development of IMAC (International Media and Cultures), a division of the American dairy and Food consulting laboratories Inc., of Denver, Colorado, USA, for coding and compiling the data, and for helping to prepare this research article. Thanks, are also extended to the various dairy product manufacturing facilities especially cheese plants in USA, South America, British Wales, Scotland, Northern and southern Ireland, and Southeast Asia. A Special thanks to the researchers participated in the study from Oxford University, England, and Melvern Instruments personnel. Deep gratitude to Mr. Rasheed Hussain and Mr. Sridhar Reddy for their contribution to graphs and tables that are presented in the research article.

Read more about Lupine Publishers LOJ Pharmacology & Clinical Research Click on the below link:

No comments:

Post a Comment

Note: only a member of this blog may post a comment.