Lupine Publishers | Journal of Textile and Fashion Designing

Abstract

Keywords: Pulp; Speck; Elastic element; The force of the bunch; The dry friction force; Kolkova drum; Surface netted; The angular velocity

Introduction

There are also attempts to describe the process by empirical formulas based on experimental material [7]. Despite the fact that the models adequately solve the tasks assigned to them, due to accepted assumptions in the development or in the analysis of models, some questions were not answered, which served as the development of a dynamic model that takes into account the masses of the mote associated with fibrous material by an elastic bond, interacting with the surface of the material by the force of dry friction. Let the fibrous mass contain a mote with a mass that is connected to it by an elastic element and by the force of dry friction. Depending on the location in the composition of the pulp, we divide the trash into two types. The first type of trash is located on the surface of the scrap and is in contact with the mesh surface. Such mote has an angular velocity equal to the speed of the spike, and in addition, under the action of a centrifugal force, they preferentially move through the opening of the mesh in the radial direction from the center.

The distance from the center to the mote will be denoted by, we assume that the mote is connected to the fibrous mass through an elastic element with variable rigidity and write down the equation of motion of the mote.

Where - coefficient of stiffness of a bundle of a mote with fibers and depends on the displacement r -R , T.e. kc = kc(r -R) , where function k (z) is determined experimentally and has a monotonically decreasing character, and after detachment of the mote from the fibrous mass, it vanishes, i.e. should be taken kc (z) = 0 at z > z0 . In particular, this function can be chosen in the form of a piecewise constant k = k0 at z < z0 and k = 0 at z > z0 or piecewise linear k = kx (z" - z) at z ≤ z(| and k = 0 at z ≥ z0 Moving r(t) satisfies the following initial conditions r = R, r = Rωα2 at t = 0 In this case, the leaving time t = tk the mote of the mesh surface is determined from equations:

k[r (tk) - R] = 0

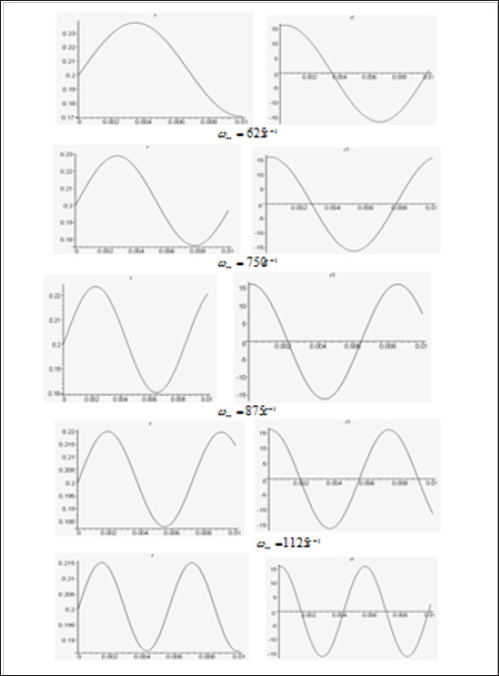

If to ≤ tk then the mote has time to leave the surface of the grid during the contact of the scrap with the surface of the grid, but if to > tk , then the mote after the interaction of the scrap with the reticulate surface does not leave the scrap and continues to move with it. The results of integrating equations (1) are presented in Figure 1. The second type includes the mote, which is in the composition of the pulp at a distance from the center of the drum, and r1 < R . In this case, these kinds of trash move for some time in the region within the fibrous mass, the movement of the trash relative to the scrap preferably in the radial direction [8-10]. To compose the equation of motion of the mote, we assume that the force of the bond between the mote and fibers acts on the mote, and also the frictional force at the surface of their contact as a result of the movement of the mote relative to the fibrous mass.

Figure 1: Obligations of radial displacement mote for time for different values of movement angular velocity of the drum.

By supplying the expressions for the kinetic energy (3) and the generalized force (7), we form the equation for the definition of the variable r .

On Figure 2 the curves of the distance dependence r(t) (m) and the rate of moth removal r(t) (m/c) in the case when θ = ωbt , kc = kc0 = const Calculations were made for different values of the parameter ω** =√kc /mc (1/cek) ? With small masses of mote,this value can assume large values. Therefore, calculations were carried out for ω** > 500 1/ cek. The calculations also R = 0.2 , ωb = 80 1/cek, f = 0.3 ,θO= 200,√k/m = 801/cek

Figure 2: Dependence of displacement r(t) and speed r1 = r (e) of time for different values of the parameter ω**(c-1 )

then specks with a parameter ω** = 1000 will also be deleted.

then specks with a parameter ω** = 1000 will also be deleted.Conclusion

For more Lupine Publishers Open Access Journals Please visit our website:

http://lupinepublishers.us/

For more Fashion Designing open access journals Please Click Here:

https://lupinepublishers.com/fashion-technology-textile-engineering/

To Know More About Open Access Publishers Please Click on Lupine Publishers

No comments:

Post a Comment

Note: only a member of this blog may post a comment.