Lupine Publishers| Latest Trends in Textile and Fashion Designing (LTTFD)

Abstract

In article it is showed the definition technological parameters of one chamber two saw cylinder gin. For maintenance of efficiency of ginning and productivity increase it is necessary to choose correctly diameter of the working chamber, an arrangement corner saw cylinders under the relation of a horizontal axis. These factors are major factors influencing productivity and quality of a fiber at practical and theoretical researches of one chamber two saw cylinder gin.

Keywords: Regression Model; Optimization of Parameter; Angular Position; Saw Cylinder

Introduction

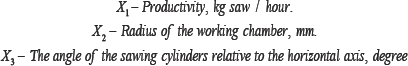

The choice of the necessary technological parameters is the main responsible stage in the design of cotton gin with new working bodies. In the process of fiber separation from the seed, the increase in productivity and the effective elimination of seed damage depend on the selected input parameters. The use of mathematical methods in planning practical experimental work in comparison with other methods of calculation, optimization parameters allows determining the influence of several factors acting together and their interaction among themselves in terms of separation. As a result, based on the few experiments that have been carried out, it is possible to obtain a mathematical model of the object under study; this model will allow obtaining optimal solutions at the time. In optimization, the main issue is this determination of the important factors affecting the process of hair removal of cotton fiber from seed this will serve for efficient fiber separation in the process of ginning [1-3]. The following parameters we chose for optimization:

Using the results of the theoretical study including the literary survey of gins and also taking into account the primary one-factor experiment, the choice of the output parameters affecting the incoming factors was chosen as follows.

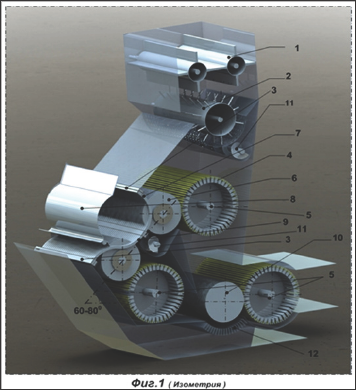

Feed rolls 1 feeding the pin drum 2, a bracket and a clamping bar 3, a brush drum 4, a shaft of the brush drum 5, a saw cylinder 6, an upper grate 7, a gin working chamber 8, a lower grate 9, a cement cylinder 10, a screw 11, knife-like mesh surface 12 (Table 1) and (Figure 1).

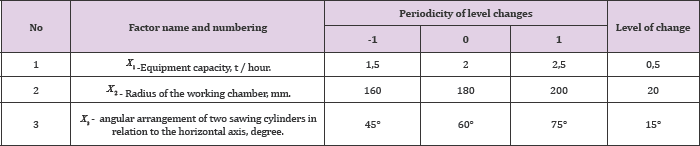

Table 1: Factor name and numbering.

Figure 1: New Gin Machine.

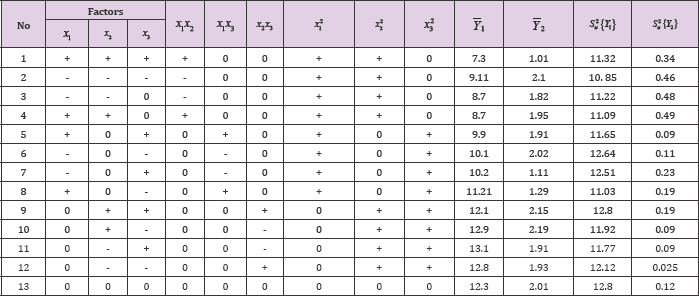

The theoretical studies, it was justified to create a new design for two-cylinder gin. The main working body of the new design is an additional saw cylinder, which allows uniform rotation of the raw roller of productivity. To ensure the efficiency of fiber separation and increase productivity, it's necessary to choose the diameter of the working chamber correctly, the angle of the sawing cylinders in relation to the horizontal axis. These factors are the main factors effecting the productivity and quality of fiber in practical and theoretical studies. The process of ginning associated with many factors is investigated by modern mathematical methods of planning and is calculated by modern computer programs with the help of a computer [4-6]. These methods allow you to get the optimal solution with the least cost. On the basis of the indicators of natural factors, we turn to the coded indicators. The full-factorial test results showed that the investigated process is expressed by the high-level equation. Because of this, to obtain a regression mathematical model of the second degree, this model is considered to be simple and convenient in comparison with other methods, and also in the primary cotton processing enterprises, a non-method method is widely used in technological processes. It was chosen and used in the conducted experiment. The results of the central non composite experimental matrix are given in Table 2.

Table 2: Central non-composite experimental matrix.

For each experiment it is necessary to use instruments with high accuracy of measurement. In our studies, to change the dimensions of the working chamber, we used already prepared working chambers of different diameters.The fiber performance we determined by the existing method and formula. When using a new working chamber, 100 kg of raw cotton was shipped from the feeder hopper. Each variant of the experiment was conducted five times. In the course of the experiment, the angular arrangement of the saw cylinders with respect to the horizontal axis exerted a great influence on the productivity. The design of the working chamber was made with a high level of measurement. The experiments were conducted according to the principle of randomization. After each experiment (at a certain time), the fiber yield level is determined. After the experiment, the samples were tested according to standard requirements in special laboratories for fiber and mechanical damage to the seeds. Based on the results obtained during the experiment, we use a multifactorial regression mathematical model of the second degree.

Read More About Lupine Publishers Latest Trends in Textile and Fashion Designing (LTTFD) Please Click on Below Link: https://fashion-technology-lupine-publishers.blogspot.com/

No comments:

Post a Comment

Note: only a member of this blog may post a comment.