Lupine Publishers| Journal of Robotics & Mechanical Engineering

Abstract

Mexico is the world largest producer of cactus pear (Opuntia spp.) and is searching for new processes that allow to export them. The fruit is rich in nutrients but is highly perishable having ambient shelf life of 9 days. Cauterization and cryo-cauterization techniques have increased shelf life to 2 and 3 months without refrigeration. An automatic system was developed to flip the fruit towards the dry-ice wall inside a chamber. A horizontal actuator pushed the container to cauterize the fruit. The entire cauterizing process for each fruit lasted 23 seconds. By exchanging the dry-ice wall every 500 fruits, a 100% cauterizer efficiency was achieved.

Keywords: Automatic Chamber; Cauterization; Prickle Pear; embedded system

Introduction

Cactus pear (Opuntia spp.) is a fruit produced in arid and

semi-arid regions around the world [1]. Mexico is the world’s

largest producer of cactus pear (Opuntia spp.) with 79.4% of world

production, and with 49,165 ha under cultivation [2]. Italy is now

the world’s largest exporter of cactus pear to the European Union

(EU), producing about 87 thousand tons annually in Sicily, which

corresponds to 96% of the total Italian harvest [3]. Cactus pear is

generally consumed fresh, but is highly perishable, showing high

incidence of spots and rotting after 9 days. After 20 days at ambient

conditions, almost 70% of the fruit was visibly damaged [4]. By

cooling prickle pears to 10 °C, shelf life increased to 6 weeks [5].

Fresh cactus pear shelf life can be increased to 32 days in modified

atmosphere packaging with less than 20 kPa CO2 [6]. A cauterizer

cut and seal 120 pieces of fruit per hour [7]; cuts were made close

to the cactus cladode at 150 °C during harvest, destroying thorns.

After 2 months of storage, 78% of the pears were unspoiled.

The application of uniform heat treatments has been effective in

controlling postharvest diseases, but can damage the treated fruit

tissue if not applied carefully. Excessive heating period may damage

the fruit, while insufficient heating may leave non-sterilized surface

segments [8]. Further developments of cauterizer machines by

Hahn [9-12] applied heat to sliced pears. After applying a constant

pressure of 100 kPa at 200 °C during 30 s to harvested cactus pears

increased shelf life to 2 months, controlling effectively postharvest

diseases [9]. However, heat application is expensive when many

fruits are cauterized. A cryo-cauterization process used a pneumatic

robotic gripper to press a cactus pear against a dry-ice wall within

a thermally isolated chamber. Fruit cryocauterizing at 150kPa for

15s increased shelf life to 90 days, keeping 86% of marketable fruit

[11].

Automation of agriculture tasks have improved pre-harvest,

harvest and post-harvest stages. Machine vision sorting of fruits

presents advantages of high accuracy, precision and processing

speed [13]. Non-contact detection makes grading and sorting free

of mankind diseases. Fruits and vegetables produced in farms are

sorted according to quality and maturity levels and decisions taken

of the market it can be sent on the basis of transportation delay

[14]. Post-harvesting operations require quality detection [15] and

skin defects [16]. A pepper robotic harvester system [17] avoiding

stem and fruit damage would be highly successful. Although food

processing methods extend the shelf life of fruit and vegetable

products, fresh-cut produce may lead to flavor loss, discoloration,

rapid softening, and increased rate of vitamin loss [18]. Emerging

smart packaging reduce losses, maintain quality, add value and

extend shelf-life of agricultural produce [19]. It alerts the consumer

from contamination of pathogens, pesticide residues or food

degradation in food packaging products [20]. Intelligent packaging

with nano sensors senses and informs the condition of the product to

provide information about quality during transport, distribution,

and storage [21]. This technology may also be used to detect

adverse reactions in consumers after taking food such as gluten,

peanuts and tree nuts [22]. Automation for the application of these

sensors is considered a future close innovation. In this paper, an

automatic system used for prickle pear cryo cauterization within

a very small chamber was developed. The chamber size obeys to

the rapid melting of dry-ice caused by environmental conditions.

A minimum number of operations is required and the system

efficiency evaluated to cauterize 120 pears per hour.

Mechanism for Pear Cauterization

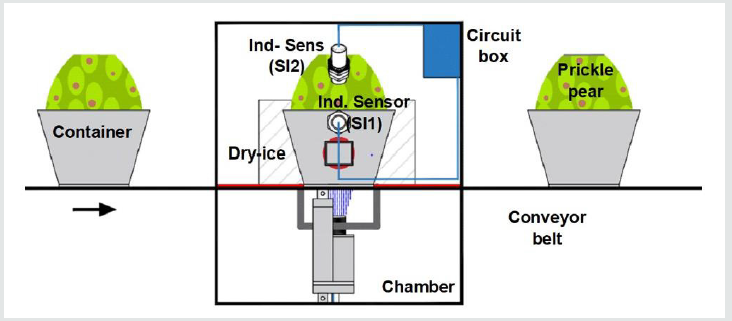

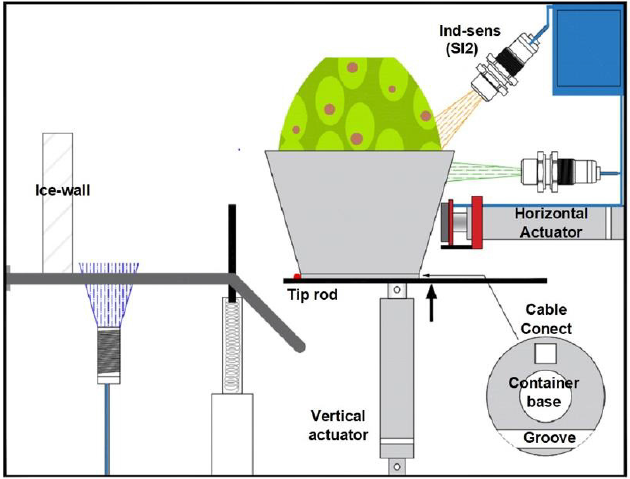

The top-surface sliced prickly pear is moved within a container into the cryo-cauterized chamber (Figure 1) by means of a conveyor belt. This band transports the fruits in a direction parallel to the dry-ice wall where cauterization takes place. A trapezoidal metal container resembles a porcelain coffee mug and holds the prickly pear (Figure 2) whose flat base stops at the bottom. The container base is 3mm thick (Figure 2) and has force sensor in between the base and the prickle pear. The system mechanism has to perform the following functions:

1. Detect when the prickle pear is present within the metal

container.

2. Rotate it 9° counterclockwise.

3. Displace it against the dry ice wall.

4. Return it and deposit it to the original band.

During the first stage, a conveyor belt transports the prickle

pear to the cauterizer chamber rising the door in the left side. At

the same time, it opens another door to exit the previous cauterized

pear. For the second function, the mechanism used an actuator

(A1) to flip the metal container (Figure 2). The linear piston or

actuator (mod. LA 14, LINAK, Denmark) is characterized by its

compact size being ideal for this chamber having a limited amount

of space available. The aluminum actuator is used in harsh and cold

environments up to -40 °C. A metal ring with a sectional groove is

located at the container base (Figure 2). The lower piston plunger

enters the groove and as it moves upwards, it turns the container

base (Figure 3); a tip rod flips the container as the piston rises. After

45 or 50 degrees of rotation, the actuator rod gets out of the groove

and the container falls by gravity. A small compression spring stops

the container reaching its end point over a pair of rails (Figure 3).

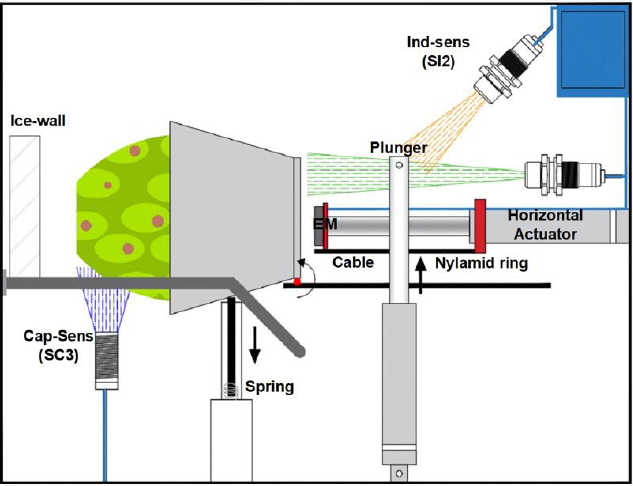

The third operation requires of a second electric actuator (A2) that

pushes the container together with the fruit until it reaches the

dry-ice wall, where it will stay pressurizing the pear for 15 seconds.

Fruit moves at most 5cm over two rails before it reaches the dry-ice

wall. The electric actuator (mod. LA 25, LINAK, Denmark) presents

a speed of 20mms-1, withstanding cold temperatures of -25 °C.

The fourth operation returns the container with a 12 VDC round electromagnet mounted at the end of the piston rod. After activating the 30mm diameter electromagnet, the container remained fixed and forced to return. A micro switch (MS1) was activated at the runend, and the voltage supplied to the electromagnet was interrupted releasing the container that felt to initial band position. The voltage supplied to the horizontal actuator was also cut.

Electrical Automation

Once implemented the chamber with its mechanisms, the sensors for automation were obtained. The process begins when the conveyor belt is turned on, which will enter the cauterization chamber and an inductive presence sensor (SI1) will detect when it is in the desired position. This sensor will serve to turn off the band and at the same time it will feed the actuator (A1) so that its rod moves upward, initiating the rotation of the container. The rod or plunger will come out from the container base and an inductive sensor (SI2) provides a signal to limit its travel. The container flips unto a pair of rails and a capacitive sensor (SC3) detects its presence, and its signal activates the horizontal actuator (A2). Its plunger with the electromagnet at its end pushes the fruit container towards the dry-ice wall. The force sensor (SF) starts measuring when the prickle pear touches the wall. The contact is maintained for 15 seconds and at the same time a negative voltage is applied for 5 seconds to the vertical actuator so that it returns to its initial position. Force sensor resistors (FSR) provide a resistance that is inversely proportional to the applied force and can measure grabbing and pressing. Flex Force sensors enable non-intrusive static and dynamic force measurements presenting better force linearity, hysteresis and temperature sensitivity than other thinfilm force sensors [23-25]. Voltage processing was done through a Wheatstone bridge having the variable flex force sensor in one arm as in the data glove [25]. The output voltage is compared and the output provided to the embedded system. At the end of the cauterizer time, the electromagnet (EM) is activated and the polarity of the horizontal actuator is reversed until it touches a micro switch (MS1). When MS1 is actuated, the electromagnet and the horizontal piston are turned-off allowing the container to fall by gravity onto the conveyor belt. The band turns on and a new cycle starts taking out of the chamber the cauterized fruit and putting in the prickly pear to be treated. Figure 4 shows the cauterizer system timing chart for automation.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.