Lupine

Publishers- Environmental and Soil Science

Abstract

Due to increasing environmental radionuclide background, the

scientists and specialists constantly face the problem of developing

technologies

for producing plant-based, therapeutic-purpose foods and food

supplements enriched with biologically active substances, which are

characterized

by high immunomodulating, radioprotective and antioxidant activity. From

such therapeutic-purpose foods and food supplements, of particular

importance are the beverages because their improved composition, sensory

and liquid consistency provide high availability and increased

therapeutic capacity.

Introduction

Natural and special wines form the great part of the export

potential of Georgia. The fact that according to figures on exports

of wine and alcoholic beverages only for the first nine months

of 2017, Georgia exported 52.7 million bottles (0,75 l) of wine.

According to the National Wine Agency, wine exports have grown

up on 63% in comparison with corresponding period last year

[1,2]. It is also noteworthy that since the 80s of the last centuries,

poor-quality and expensive sprays and brought to our country

have caused significant damage to the indigenous and alien grape

varieties. Georgian farmers were forced to switch partly to growing

of nontreated and hybrid grape varieties, because they do not

require expensive and imported from outside sprays, and besides,

hybrids and clones are easy to grow, and different types of fungi

and other diseases are no big deal for them. Today, wineries cannot

apply even industrial varieties of colored grapes such as Aladasturi,

Dzelshavi, Mgaloblishvili and Black Pinoa [3,4].

In view of the foregoing, it reasonable and relevant to develop

the innovative technologies for producing natural and special wines

from common to western Georgia Therefore reasonable and relevant

to western Georgia-known less marketable local raw materials

of colored grape industrial varieties and nontreated grape clones

enriched with from biologically active substance enriched with

innovative technology of special wines, which are characterized by

high sensor, radioprotective and antioxidant activity therapeutic properties for preventing food-borne diseases [5-7]. The goal

of the work is to develop special wine technology enriched with

biologically active substances from the grape raw materials of grape

varieties cultivated in the Imereti Viticulture and Winemaking

Area, which is characterized by improved sensory indicators and

increased therapeutic and preventive capacity. In addition, in this

special wine technology, for the first time in Georgia, there will be

used raw materials of the nontreated colored Zeibeli grape variety

cultivated in the Baghdati Viticulture and Winemaking micro-zone,

rosehip and grape-seed alcohol-wine extracts and small quantity

of white honey for the purpose of increasing the flowers tonality.

Objectives and Methods

Object of Study

Raw materials of “Otskhanuri Sapere” grape variety from the

Imereti Viticulture-Winemaking subzone, particularly from the

Zestafoni district’s village of Sviri and the Bagdati district’s village of

Obcha; raw materials of “Aladasturi” grape variety from the Middle

and Lower Imereti Viticulture-Winemaking subzone, particularly

from the Bagdati district’s village of Rokhi and the Vani district’s

villages of Pereti and Kumuri, from the Patele Area’s vineyards;

raw materials of “Zeibeli 5455” (“Zeimberi”) grape variety from

the Lipnari vineyards; vacuum-must; grape-seed extract; wildgrowing

dog-rose from the Zekari and Sairme valleys and extracts and concentrates obtained from their skins and fleshes; lime-tree

flower honey from the Zekari and Sairme valleys; rectified ethyl

alcohol [8].

Research Methods

When determining the physical-chemical indicators of grape

raw materials, wine materials and finished special wine, we used

the standard, universally accepted and modified organoleptic

and physical-chemical methods, including chromato-massspectrometry,

high-performance liquid and gas chromatography,

spectrophotometry and fluorometry

Results and Analysis

To implement this goal, the following objectives should be

attained [9-14]:

a. To study the mechanical composition of selected raw materials;

b. To provide uvological evaluation of raw materials;

c. To study the chemical composition and sensory characteristics

of raw materials;

i). To justify theoretically and experimentally the optimal

composition of grapes raw material required for special wine

ii). To develop rational technology of colored grape raw materials

processing, alcoholic fermentation and ageing;

iii). To study the influence of thermal conditioning regimes of

the seeds and skins on the extraction of phenolic and dye

compounds;

iv). To develop the optimal technological regimes and approaches

for the production of ingredients required for special wine:

semi-fermented wine, condensed grape vacuum-must, and

grape-seed and dog-rose extracts;

v). To provide quantitative and qualitative evaluation of

biologically active substances of special wine;

vi). To develop technological schemes for producing ingredients of

special wine;

vii). To develop technological schemes for special wine production;

viii). To assess sensory characteristics and antioxidant activity of

special wine.

ix). At the initial stage we studied and evaluated the mechanical,

physical, chemical and sensory characteristics of the selected

grape raw materials.

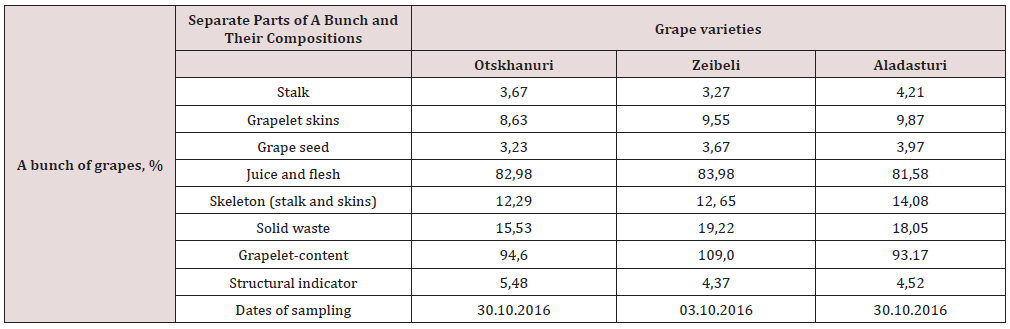

The grapes are the main raw material for wine production,

and we have identified the mechanical composition of the bunch

in compliance with the requirements suggested by Prostoserdov.

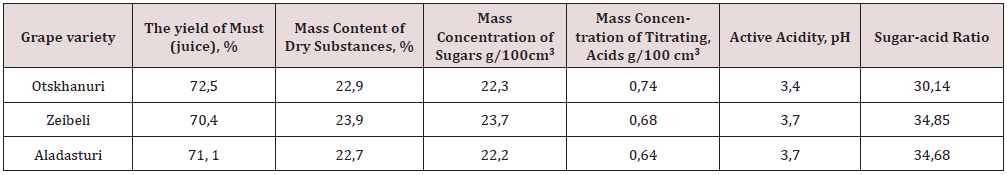

(Table 1) We have carried out studies and evaluation of the

chemical composition and variety flavor of selected grape raw

materials (Table 2). Studies show that the value of sugar-acid ratio

affects numerous characteristics of wine, in particular the higher is

this ratio, the better is the quality of special wine. Along with the

selection of high-quality raw materials in the production of red

special wines, the fermenting and fermentation processes have the

main function in the formation of a sensory bunch [15,16].

The List of the Proposed Innovations is as Follows:

I. Adding of pectolytic (with activity 2000-2200 unit/g) enzyme

(Rapides CR) to the seeds and skins during the process of

pressing in a grape stalk separator, increases the yield of the

must by 5-7% and the content of biologically active substances

for 1-2 ml/100 kg.

II. Adding of potassium metabisulfite within 54-63 mg/dm3

significantly increases extraction of anthocyanins, increases to

1.2 - 4.3 g/dm3 the reduced extract and the content of dyes,

contributes to purification, the growth in terpenic compounds

by 2,1-2,7%, and the growth in a stable fraction of a phenolic

complex (within 20-25%) in wine.

III. We added 1-2% of Aspergillus fungus of the dry active yeast in

a grape stalk separator (C-R-9001 or C-RB-9001- fungus works

at the temperature of 12 - 280C, pH=3.0-5.4 and increases

alcohol content up to 24%, and significantly increases the

content of terpens and esters in wine).

IV. Adding of the condensed concentrate with the content of

dry substances up to 54-63 % through the dog-rose lyophilic

drying to the seeds and skins within 50-75 mg/dm3, in the

presence of or cadifite (40-70 mg/dm3) either SO2 (90±10 mg/

dm3) increases by 1.5-1.8 the development of variety flavor in

a special wine.

V. During the fermentation of the seeds and skins, we raised

the sugar content up to 27% by adding the vacuum-must and

honey, due to which terpenic compounds were increased by

0.7-1.2 %, and esters by 24-27%.

VI. We have established that after tye 6-day extractionfermentation

at a temperature of 270C, the seeds and skins are

subject to heat treatment at a temperature of 540C, and hot

pressing, which significantly increases separation of phenolic

and dye compounds.

VII. Adding of the grape-seed and dog-rose concentrates and

heat-treated grape-seed (5 g/dal) and oak shavings (5 g/dal)

significantly improves the rancio tones and sensory bunch.

VIII. In 16-18 months, adding of dry dog-rose pulp and peel (20 g/

dal) increases the flavor-forming complexes.

IX. Adding of the grape-seed and dog-rose concentrates and

heat-treated grape-seed during the ageing process, under

conditions of periodic pasteurization and stirring within 2-3

months, increases the total amount of phenols by 0.3 - 0.4 g/

dm3, and improves the rancio tones and sensory bunch.

X. Prohibition of using gelatin and bentonite clays, because

for processing wine materials, bentonite clays reduced the

anthocyanins by 27-36% on 2-3 kg/t, while the use of gelatin

reduced the compounds of phenolic compounds by 6-9% on

2-3 g /t.

XI. Creating a new technology by using new varieties and honey

flower tones.

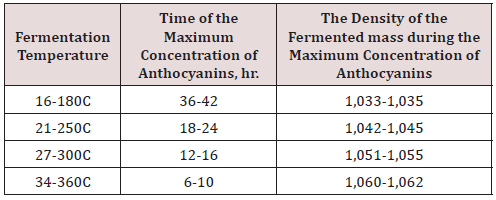

XII. We have studied the impact of the temperature of the

fermentation of the seeds and skins on the extraction process

anthocyanins from the skins in the fermenting mass. Studies

were carried out at four temperature intervals 34-360C, 27-

300C, 21-250C and 16-180C.

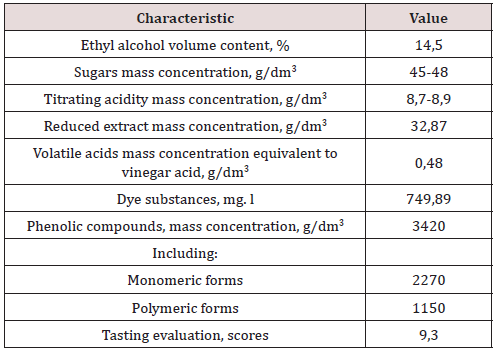

Table 3 shows the main fermentation temperature, the

duration of maximum extraction of anthocyanins and the density

of the fermented mass. Table 4 contains the physical, chemical and

sensory characteristics of the special wine after the 18-month aging.

In all five samples, the content of raw materials of Zeibeli grape

variety varied between 10-20%, while the amount of raw materials

Aladasturi and Otskhanuri Sapere grape varieties - between 20-

50%. Aladasturi and Otskhanuri Sapere grape varieties were

blended in the proportion 36:48:16 (percentage ratio). As shown

from the table, the wine produced has a high sensitivity rate (9,7

cents), which is the result of the composite effects of the selected

raw materials of the selected raw materials, the use of ingredients

and the technological processes of individual technologies.

Conclusion

A. It has been experimentally determined that the grape picking

should be done when the concentration of the sugar content

in the grapes is not less than 23-24g/100 cm3 and titrated

acidity is 6-8 g/dm3. And pressing of grapes in a rolling grape stalk separator enriches the seeds and skins with the phenolic

complexes of stalk.

B. It has been established that colored grape raw materials

blended with an optimal ratio of “Aladasturi”, “Otskhanuri

Sapere” and “Zeibeli 5455” grape varieties is promising for the

production of high-quality special red wines with a distinctive

variety flavor, and rich technological reserves of phenolic

(3765-4314 mg/kg) and dye (976-1432 mg/kg) compounds.

C. The optimal version of blending for producing a special dessert

wine with the best sensory bunch has been determined

experimentally:(“Otttsanuri Sapere”): (“Aladasturi”): (“Ziebeli

5455”) = (27-36%): (42-54%): (16-18%).

D. It has been investigated that in the process of pressing in a

grape stalk separator, in the composition with the enzyme

preparation Rapidase CR the kernel gap in the 1-2 mL / 100 kg

of enzyme preparation in potassium metabisulphite with 54-

63 mg/dm3 and special (dry active yeast) Aspergillus fungus

1- 2% Composition (CR-9001 or C-RB-9001-fungus works at

temperature of 12-280C, pH = 3,0-5,4 and stands alcohol up to

24%), increases the the yield of must, sensory characteristics,

the content of extractive (increases the reduced extract up to

1,2- 4,3 g/dm3) and dye substances in wine and contributes to

its rapid purification.

E. It has been established that sulphiting of the seeds and

skins with potassium metabisulphite with 54-63 mg/dm3,

contributes to the emergence of the variety flavor (increase of

terpenic compounds by 2,1-2,7%) and the increase in phenolic

complex (within 20-25 in wine).

F. There has been determined the relationship between the

creation of the flavor-forming complexes and the sugar mass

concentration in grapes raw materials, in particular the

content of terpenic compounds is increasing by 0,7-1,2%, and

the content of esters-by 16-27% when the sugar content in

grapes raw materials is 22-27 g/100 cm3, then when sugar

content in the grapes is less than 18.6%.

G. It has been studied that through the dog-rose lyophilic drying

until 54-63%, adding of the condensed concentrate to the

seeds and skins within 50-75 mg/dm3, in the presence of or

cadifite (40-70 mg/dm3) either SO2 (90±10 mg/dm3) increases

by 1.5-1.8 the development of variety flavor in a special wine

H. It has been experimentally determined that during the aging

process of wine material, adding of:

i). dehydrated dog-rose pulp and peel at 20 g/dal,

ii). thermally-treated oak crumb at 5 g/dal,

iii). thermally-treated grape-seed at 5 g/dal

I. Under conditions of periodic pasteurization and stirring

within 2-3 months, increases the total number of phenols by

0.3-0.4 g/dm3, improves the rancio tones and sensory bunch.

J. It has been established that after completion of ripening (16-

18 months), adding of dog-rose condensed extract to wine

material within 50-70 mg/dm3, slows down the phenolicquinone

transformations and increases the flavor-forming

complexes.

For more Lupine

Publishers Open Access

Journals Please visit our website: https://lupinepublishersgroup.com/

No comments:

Post a Comment

Note: only a member of this blog may post a comment.