Lupine Publishers | Journal of Veterinary Science

Abstract

Introduction

Material and Method

Starter cultures

A commercial mesophilic Saccharomyces Cerevisiae starter culture obtained from (Pakmaya instant yeast, made in Turkey by Pak Gida) was used in bread manufacture as a negative control. One selected strain MY Saccharomyces Cerevisiae from my identified yeasts isolation (my previous work in protein research department- GEBRI/ SRTA- City) was used in four treatments and positive control to improve, increasing protein and amino acids content, fortification and enhances the flavor and texture of bread. MY Saccharomyces Cerevisiae was grown in YPD medium (10g/L yeast extract; 20g/L peptone; 20g/L glucose) broth at 30-35oC for 24-48h. then centrifuged on sterilized cups at 3000rpm in 25oC for 10 min to remove broth medium, then inoculated overnight in sterilized skim milk at 30 - 35oC, then re-centrifuged to get mediumfreelive cells. The viable count of Saccharomyces Cerevisiae after incubation was 6-8×104 CFU/g by Homothito meter method.Bread Preparation by Straight-Dough Method

The straight dough method is the easiest of the dough-making methods where all the ingredients are mixed at the same time in the mixer as described by Ayele [8] with some modification. The bread was reformulated by adding a commercial Saccharomyces Cerevisiae starter culture at 5g/kg wheat flour as a negative control, and selected strain MY Saccharomyces Cerevisiae at 5g/ kg wheat flour as positive control. Several of MY Saccharomyces Cerevisiae at concentrations of 10g/kg, 15g/kg, 20g/ kg and 30g/ kg wheat flour were prepared. Wheat flour was mixed with salt (10g/kg), sugar (30g/kg), live cell of starter culture Saccharomyces Cerevisiae (divided for negative control, positive control and other treatments) and water to make dough. Proofing of the dough was done at a standard time of 50 - 60 minutes at 30-35oC as first fermentation, then divided to five parts for positive control and treatments. More addition of Saccharomyces Cerevisiae live cells at 5, 10, 15, 25g /kg dough were added then putt in stainless pans and left for another 30 minutes as a final proofing step (second fermentation).Treatment and control baked in the electric oven at 250°C for 20min., then cooled for 2h., baked breads were packed in low-density polyethylene plastic bags and stored for three days at room temperature (24 ± 2°C).These dough mixtures and bread samples were evaluated for nutritional value and sensory evaluation.Quality attributes evaluation

Proximate chemical compositiona) Moisture content

The sample (5g) was transferred into a Petri-dish of known weight. The weighed sample was put into an oven at 105 oC until constant weight was obtained AOAC [9]. The difference between the initial and final weight of the sample was recorded as the moisture content.

b) Determination of total carbohydrate

Determination of total carbohydrate was done using the phenol-sulfuric acid method as described by DuBois [10]. The total concentration of Carbohydrate obtained from bread samples was: Total carbohydrate (%) = (carbohydrate content from calibration curve/weight of sample) x 100.

c) Determination of crude protein

Nitrogen content was determined after digestion of about 0.5g sample by micro-Kjeldahl method and the ammonia was received in 4% boric acid according to the method of AOAC [9]. The crude protein (%) was determined by multiplying the total nitrogen by factor of 6.25.

d) Determination of fat content

Crude fat content was determined after extraction of 3.5 g sample with 50 mL diethyl ether by Soxhlet extraction method. The solvent was evaporated. The residue was recorded as crude fat content according to AOAC [9].

e) Determination of Energy value: Energy value (kcal per 100 g) was estimated using the Atwater conversion factor (Osborne & Voogt [11].

Energy (kcal per 100 g) = [9 × Lipids% + 4 × Proteins% + 4 × Carbohydrates%].

f) Determination of Vitamin B complex: The vitamin B group was extracted according to a previously described method (AOAC1990) the prepared sample was injected into the HPLC system. Quantification of vitamin B content was accomplished by comparison to vitamin B standards. Standard stock solutions for Thiamine,Riboflavin, Niacin, Pyridoxine, and Cobalamin were prepared as reported previously Aslam [12] and Ringling [13] .Chromatographic separation was achieved on a reversed phase- (RP-) HPLC column(Agilent ZORBAX Eclipse Plus C18; 250 × 4.6mm i.d., 5𝜇m) through the isocratic delivery mobile phase (A/B 33/67; A: MeOH, B: 0.023M H3PO4, pH = 3.54) at a flow rate of 0.5mL/ min. Ultraviolet (UV) absorbance was recorded at 270nm at room temperature Marzougui [14] and Rokayya [15].

g) Determination and analysis of Minerals: The mineral contents were assessed by flame atomic absorption spectrophotometer (FAAS - Analytik Jena, Germany) according to AOAC Official Method 985.35 [16] then expressed in fresh weight (mg/100g).

h) Determination of Amino Acids: Amino acids have been extracted from the wheat bread according to Knežević [17]. Each of the defatted samples was weighed (200mg) in to a glass ampoule, 5ml of 6N HCl/L was added to the ampoule, and the contents were hydrolyzed in an electric oven preset at 105°C for 22h. Oxygen was expelled in the ampoule by passing nitrogen gas in to it. Amino acid analysis was done by (SYKAM S433 Amino Acids Analyzer). The analysis was carried out with a gas flow rate of 0.5ml/min at 60°C, and the reproducibility was 3%. The amino acid composition was calculated from the areas of standards obtained from the integrator and expressed as percentages of the total protein according to Trajković [18].

i) Sensory Quality Attributes: Sensorial quality was evaluated by a10-panalists, from dept. of food science to score quality attributes of bread. Samples were scored for overall visual quality by using an interval hedonic scale, where the extremes and center of the interval were represented as follows: zero (dislike extremely, no characteristic of the product), 5 (neither like nor dislike, limit of acceptance from the consumer’s point of view), and 10 (like extremely, very characteristic of the product). The tested attributes such as texture, taste, odor, color and appearance and overall acceptance were evaluated, according to Eddy [19]. The end of shelf-life was reached when the average value of the samples was judged as unacceptable for consumption by the sensory panel.

j) Statistical analysis: All results were presented as means ± standard deviation (SD). (n =3) Values were statistically analyzed by one-way analysis of variance (ANOVA test) according to Steel [20] using SPSS 22 software package. Differences were considered significant at (P values) less than 0.05 using Duncan Multiple Range test.

Results and Discussion

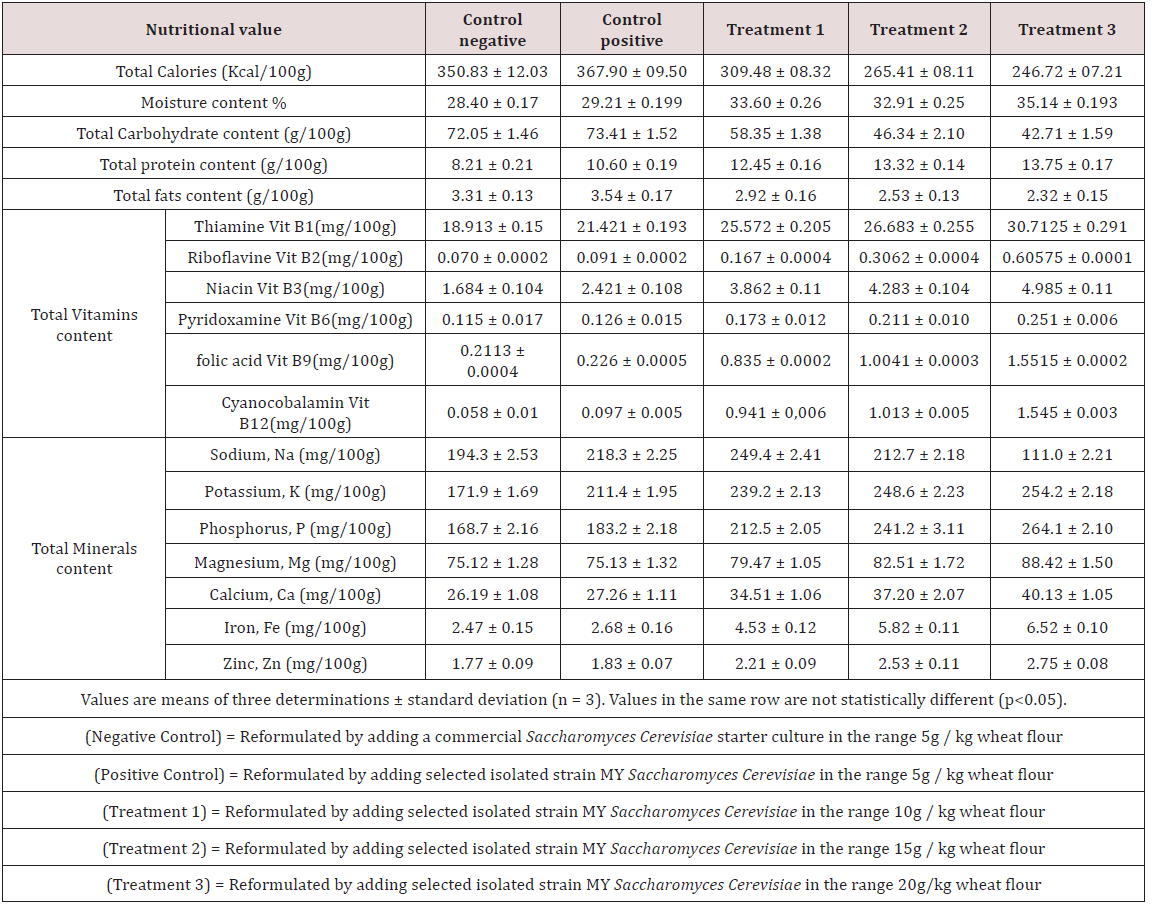

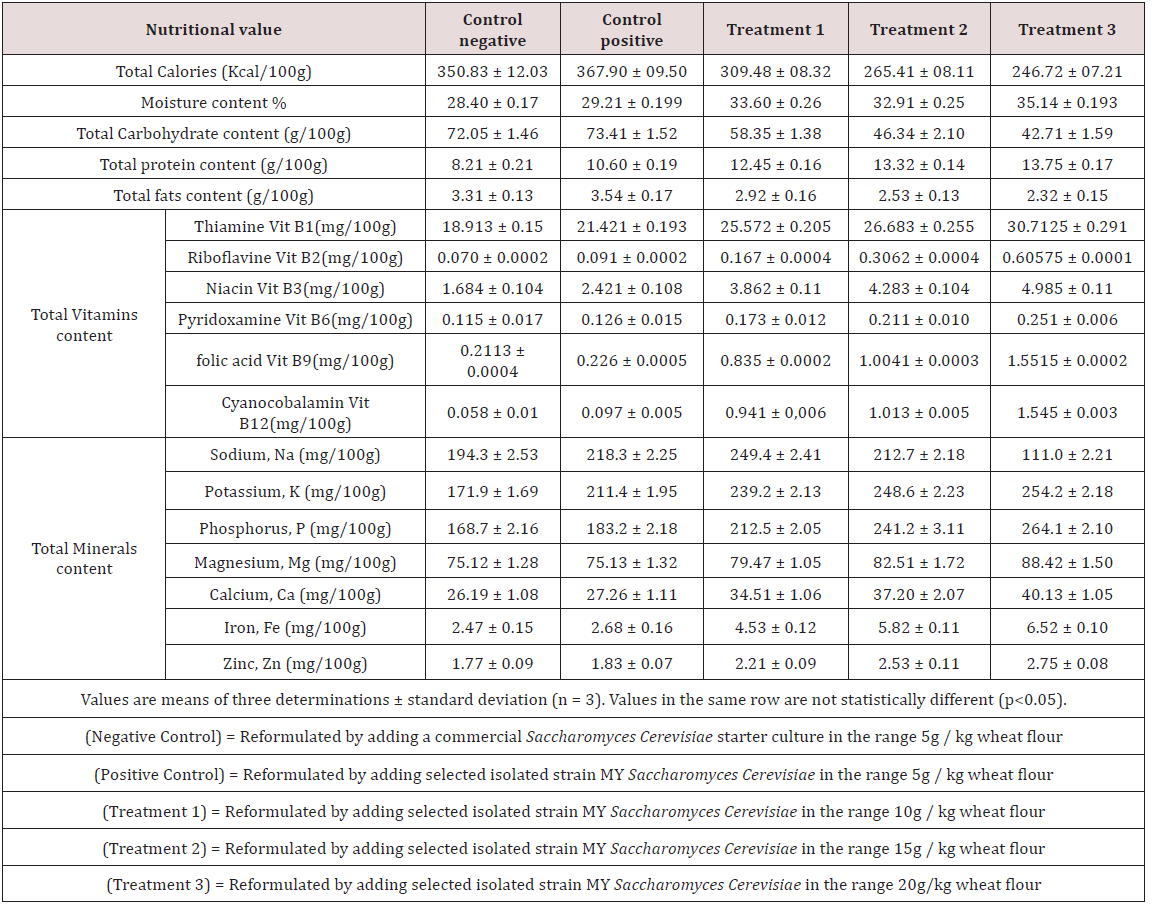

Table 1 shows the nutrient composition of bread. An increase in nutritional yeast concentration resulted in increase in the protein content of bread. Similar results were reported by Shogran [21] Udofia [22] Noorfarahzilah [23] and Masamba [24].The nutritional yeast used to fortify bread contains high quality protein which was reflected in the fortified bread. Proposed that nutritional yeast is a rich source of protein. Therefore the consumption of nutritional yeast fortified bread means exposure to higher quantity and quality protein Goesaert [25] and Gary [26]). The nutritional yeast fortified bread had a slightly higher content of carbohydrate, moisture and B complex vitamins (Thiamine B1, Riboflavine B2, Niacin B3, Pyridoxamine B6, folic acid B9 and Cyanocobalamin B12) compared to the non-fortified bread sample. These results are in agreement with Ndife [27] and Pareyt [1]. Table 1 revealed also that the fortified bread had higher content of minerals such as (Potassium, Phosphorus, Magnesium, Calcium, Iron and Zinc) compared to the non-fortified bread sample. These results are in agreement with Nwanekezi [28]. It was also noted that lipids and Sodium content were lower in fortified bread because of the addition volume of nutritional yeast. These results are in agreement with (Mashayekh [29] Sanful [30] [Table 1].

Table 1: Means of nutritional value of fortificated bread as influenced by adding three different concentrations of active Saccharomyces

Cerevisiae.

Sensory Evaluation

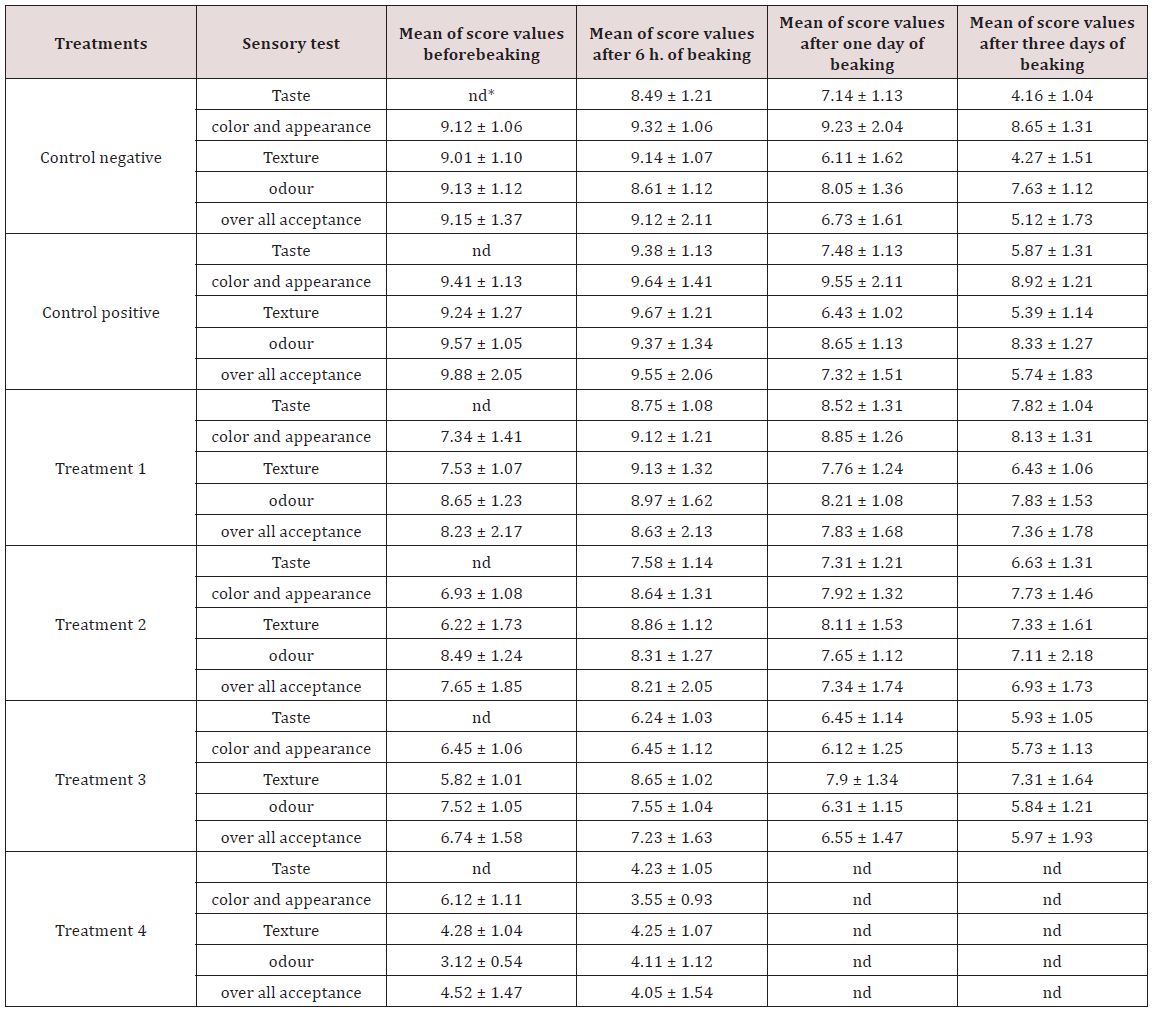

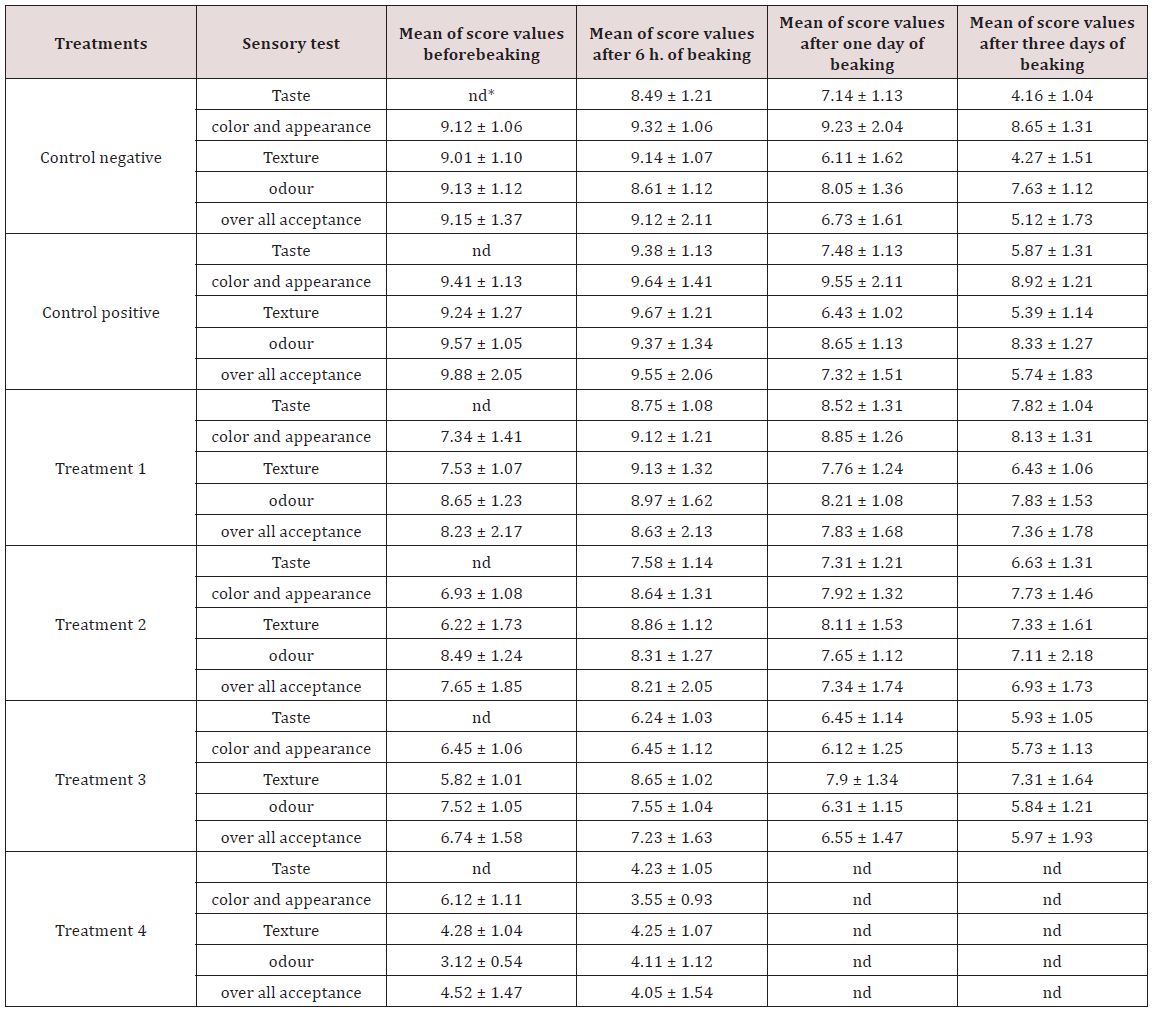

Color and Appearance of Bread: Data in Table 2 shows people responses to the appearances of bread samples. All the bread samples were baked using white flour and the change in color was a result of incorporation of different nutritional yeast concentrations. The darker color noticed in bread samples with higher concentrations of nutritional yeast was a result of enhanced Maillard reactions [42] between reducing sugars and proteins. Vaclavik and Christian [43] described appearance of food as the size, color, structure, transparency of turbidity and degree of wholeness or damage of the product. Structure and color are important in baked goods for example bread should have white and brown color and should have many holes uniformly spread throughout otherwise a slight drift from normal will be judged as a quality defect. Most people referred the appearance of bread sample T1 since it resembled the color of brown bread available on commercial market. This shows that many consumers prefer brown bread to white bread when considering color only. Sample T3was regarded as unacceptable by the respondents due to its dark brown color which they perceived as unattractive.Taste of Bread:b Taste was the main attribute in rating of the samples since addition of the nutritional yeast had an effect of changing the taste of the bread. Tepper and Ulrich [44] defined taste as a combination of five major tastes: salty; sweet; sour; bitter and umami. Taste is detected by taste buds at the tips, sides and back of the tongue and the sensitivity to a particular taste depends on the concentration of the substance responsible for the taste. The responses to the taste of different bread samples are shown in Table 2 the respondents liked the taste of sample T1 most largely because it had the taste of what they already perceive as normal and fresh bread taste. Samples T2 and T3 had low scores due to the cheese like taste of the nutritional yeast which was appealing to most respondents who originally prefer cheese. Bread sampleT4 was regarded as unacceptable for human consumption as a result of a bitter aftertaste experienced by the consumers.

Table 2: Means of sensory score values of bread as influenced by adding four different concentrations of active yeast.

Values are means of three determinations ± standard deviation (n =

3). Values in the same row are not statistically different (p<0.05).

(Negative Control) = Reformulated by adding a commercial Saccharomyces Cerevisiae starter culture in the range 5g / kg wheat flour

(Positive Control) = Reformulated by adding selected isolated strain MY Saccharomyces Cerevisiae in the range 5g / kg wheat flour

(Treatment 1) = Reformulated by adding selected isolated strain MY Saccharomyces Cerevisiae in the range 10g / kg wheat flour

(Treatment 2) = Reformulated by adding selected isolated strain MY Saccharomyces Cerevisiae in the range 15g /kg wheat flour

(Treatment 3) = Reformulated by adding selected isolated strain MY Saccharomyces Cerevisiae in the range 20g /kg wheat flour

(Treatment 4) = Reformulated by adding selected isolated strain MY Saccharomyces Cerevisiae in the range 30g /kg wheat flour

Flavor of Bread: Flavor is one of the major sensory properties

which are decisive in acceptance and selection. Vaclavik and

Christian [43] defined flavor as a combination of smell and taste

which is largely subjective. Table 2 shows consumer responses to

bread flavor of different nutritional yeast concentration. As the

level of nutritional yeast increased, the typical flavor associated

with bread decreased. The respondents accepted flavor of bread

samples T1, T2 and T3 but rejected bread samples T4 as a result of

strong yeast smell. Consumers are more likely to accept products

that they are familiar with. Any deviation in flavor is deemed as

quality defect.

(Negative Control) = Reformulated by adding a commercial Saccharomyces Cerevisiae starter culture in the range 5g / kg wheat flour

(Positive Control) = Reformulated by adding selected isolated strain MY Saccharomyces Cerevisiae in the range 5g / kg wheat flour

(Treatment 1) = Reformulated by adding selected isolated strain MY Saccharomyces Cerevisiae in the range 10g / kg wheat flour

(Treatment 2) = Reformulated by adding selected isolated strain MY Saccharomyces Cerevisiae in the range 15g /kg wheat flour

(Treatment 3) = Reformulated by adding selected isolated strain MY Saccharomyces Cerevisiae in the range 20g /kg wheat flour

(Treatment 4) = Reformulated by adding selected isolated strain MY Saccharomyces Cerevisiae in the range 30g /kg wheat flour

Bread Texture: Texture refers to those qualities of food that can be felt with fingers, tongue, palate or teeth Murano [34]. The texture of bread samples is shown in Table 2. The respondents found the texture of samples T1, T2 and T3 as highly acceptable. Sample T4was regarded as unacceptable in terms of texture due to the high amounts of moisture in the bread samples which resulted in a lumpy crumb structure instead of an open texture.

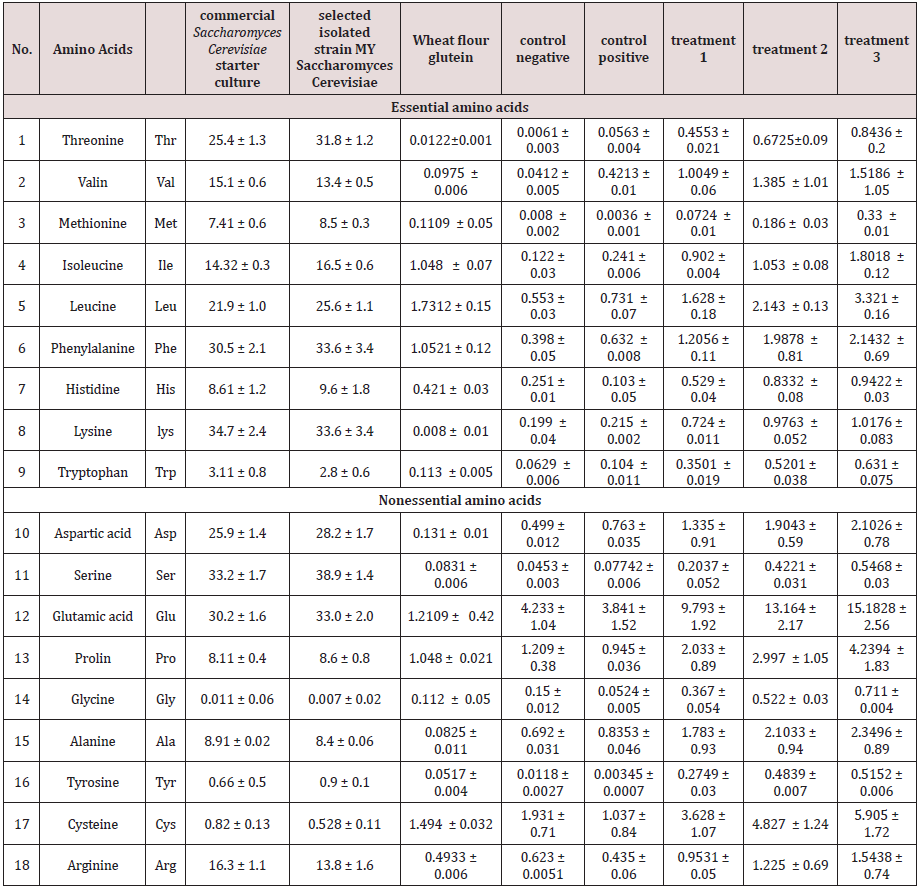

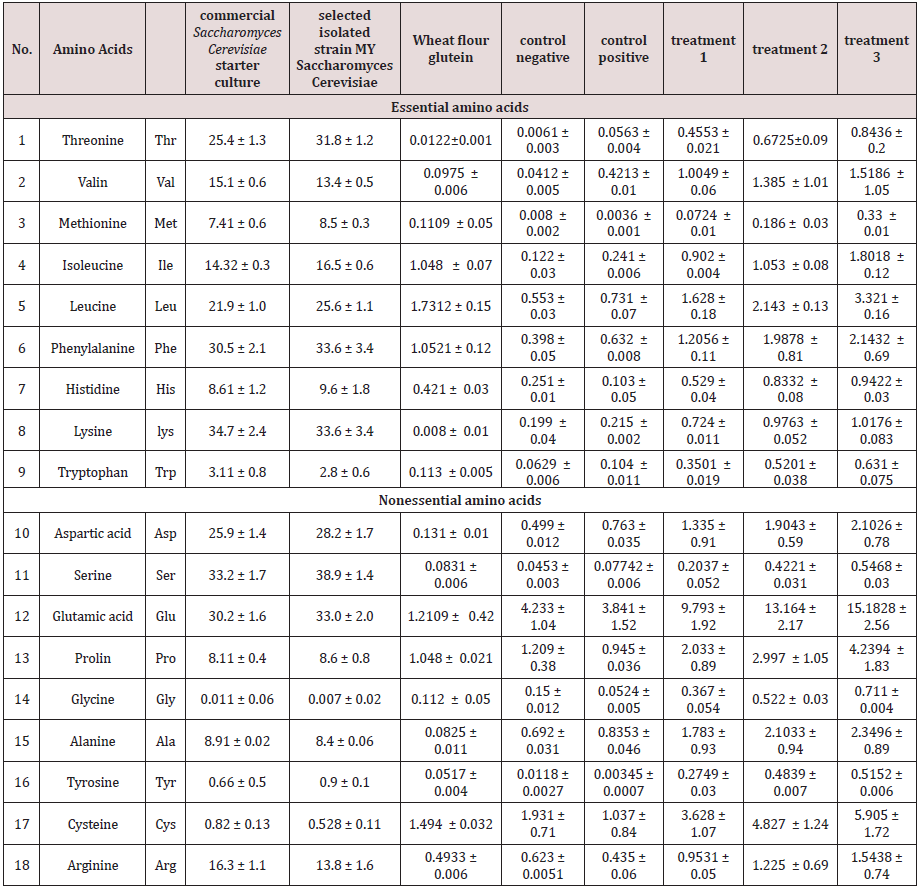

Amino acids Analysis: The results of Table 3 the qualitative analysis showed the variability in the amino acid composition in the examined wheat genotype. For all analyzed cultivars have been identified 18 different amino acids. These results suggest that wheat flour and non-fortified bread protein is deficient in certain essential amino acids, such as lysine, tryptophan, threonine, methionine and histidine. Wheat protein is rich in glutamic acid and proline, which are the dominating non- essential amino acids. Paterson [35] also reported the deficiency of lysine, tryptophan and methionine in wheat protein; likewise Khan [36] reported that lysine is the limiting essential amino acid in wheat grain protein. In contrast fortified bread treatments showed highly increase in certain essential and non- essential amino acids. At the same time it should be noted that the lysine has been higher increase value in fortified bread treatments which is in agreement with the experience of Yalçın [37] who used a similar technique with fortified bread. According to the results of the analysis the most present amino acids in the examined wheat flour were glutamic acid, glycine, sarcosine, valine, norvaline and tryptophan. It is well known, that glutamic acid and glycine are principal amino acids in all cereal protein fractions. Likewise Sejian [38] and Knezevic [39] found that increase in the protein content of wheat grain showed differences among wheat genotypes. Considering that amino acid composition of wheat flour proteins is genetically determined, it mean that changes of amino-acid composition is possible realize through changes of backing proceed. Similar results were reported by Paterson [35] there was a significant loss of lysine when dough is baked into bread. Ahmad & Hussain [40] and Jensen [41] also reported negative relation between the protein and lysine content of wheat (Table 3).

Table 3: Means of Amino acids concentration value of wheat flour and fortificated wheat bread as influenced by adding three

different concentrations of active Saccharomyces Cerevisiae as (mg/gm).

Values are means of three determinations ± standard deviation (n =

3). Values in the same row are not statistically different (p<0.05).

(Negative Control)= Reformulated by adding a commercial Saccharomyces Cerevisiae starter culture in the range 5g / kg wheat flour

(Postive Control)= Reformulated by adding selected isoleted strain MY Saccharomyces Cerevisiae in the range 5g / kg wheat flour

(Treatment 1)= Reformulated by adding selected isoleted strain MY Saccharomyces Cerevisiae in the range 10g / kg wheat flour

(Treatment 2)= Reformulated by adding selected isoleted strain MY Saccharomyces Cerevisiae in the range 15g / kg wheat flour

(Treatment 3)= Reformulated by adding selected isoleted strain MY Saccharomyces Cerevisiae in the range 20g / kg wheat flour

(Negative Control)= Reformulated by adding a commercial Saccharomyces Cerevisiae starter culture in the range 5g / kg wheat flour

(Postive Control)= Reformulated by adding selected isoleted strain MY Saccharomyces Cerevisiae in the range 5g / kg wheat flour

(Treatment 1)= Reformulated by adding selected isoleted strain MY Saccharomyces Cerevisiae in the range 10g / kg wheat flour

(Treatment 2)= Reformulated by adding selected isoleted strain MY Saccharomyces Cerevisiae in the range 15g / kg wheat flour

(Treatment 3)= Reformulated by adding selected isoleted strain MY Saccharomyces Cerevisiae in the range 20g / kg wheat flour

Conclusion

For more Lupine Publishers

Open Access Journals Please visit our website https://lupinepublishers.us/

For more Journal

of Veterinary Science articles Please Click Here: https://lupinepublishers.com/dairy-veterinary-science-journal/

To Know more about Open

access Publishers, click on Lupine

Publishers.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.