Lupine Publishers- Environmental and Soil Science Journal

Abstract

Traditional sandy soil stabilizers such as lime cement, fly ash and

bituminous materials, etc., usually require long curing time.

Hence now a day, polymer stabilizer is used more extensively because of

its stable chemical property and shorter curing time.

For the developing organization, it is important to judge the

performance of stabilized soil during its developing stages only. This

paper aims to highlight a quick and easy test to evaluate the mechanical

performance of such polymer based stabilized soil. For this

study, three different kinds of polymer stabilizers at developing stage

were evaluated against a market ready product. The analysis

of the test result include a comparison of the strength, moisture loss

rate and strain energy under different curing time, polymer

type, polymer additive amount and test conditions. This study shows that

the strength of the stabilized sandy soil is significantly

increased both under wet and dry conditions by using the polymer

additives. With the procedure mentioned in the paper it was

easier to identify the relative merits and demerits of each product.

Introduction

In the desert areas, large amount of soil is lifted by wind, the

road is covered by the soil as shown in Figure 1, therefore, soil

stabilization is important for road capacity. Soil stabilization is the

alteration of one or more soil properties, by mechanical or chemical

means, in order to maximize the suitability of soil for a given

construction purpose by improving in-situ soil properties. Soils

may be stabilized to increase engineering properties like strength

and durability; or to diminish erosion and dust generation. The

stabilized product should not only enhance desired soil properties,

but they should also create a soil material/soil system which can

sustain for the design life of the project, under designated load

application. In the field application, the polymer dilution is sprayed

normally into the loose soil. After polymer dilution penetrates

into the soil, compaction of the “wet” soil is carried out. The

stabilized soil gains strength after water evaporates from its soil

mix. Traditional stabilization of soil relies on cement, lime, fly ash,

and bituminous [1-3] material. As the scientists and researchers

are developing new engineering materials, many non-traditional

materials are available for soil stabilization, for examples polymer

emulsion, acids, enzymes and tree resin emulsions [4-7]. As

compared to the traditional stabilizers, these stabilizers have the

following advantages:

a) Stable chemical properties;

b) They produce less swelling and heaving [8,9];

c) Produce less pollution; and

d) They save natural resources.

Apart from above mentioned benefits another advantage is

that the liquid concentrate can be diluted with water and thus it

is easy to achieve target additive amount by controlling dilution

ratio. In many countries, large percentages of roads and parking

lots are unpaved. The vehicles and wind together with the loose soil

create dust that are known for adverse environmental and human

health impact. Apart from increasing the strength of the soil these

stabilizers can also be used as a way for controlling dust. For the

ease of transportation and storage these Polymer emulsions can

also be prepared in the form of powder. Before field application

it is important for the industries to understand the mechanical

properties of stabilized soil primarily during development phase of

the product. Thus, the main objective of this paper is to highlight a

quick and easy way to evaluate the mechanical performance of such

stabilized soil before actual field application. Such assessment will

quickly provide them a guide to modify their product if at all needed.

For a comparison study, three in development products from the

same company namely a) L13126; b) L13140; c) L13142 and one

a market ready “Product A” is chosen, all as anonymous reference

products. Overall, they constitute three polymer emulsions and one

polymer powder type as described later in the paper. Goals within

the scope of this paper include the following:

a) In detail description of sample preparation

b) To evaluate the property and suitability of the sandy

soil before the addition of stabilizer developed by chemical

polymerization techniques

c) To evaluate the property and suitability of the sandy soil

after the addition of the stabilizer

d) To investigate the influence of the mechanical properties

of the sandy soil with the polymer emulsion (in terms of mix

proportion, percentage of stabilizing additive, water content

and permeability of the stabilized soil matrix)

e) To demonstrate the influence of the emulsion types,

curing time and wetting condition on the mechanical response

of the stabilized soils

f) At last, present a relative ranking of various soil stabilizer

products

The outcome of the tests is analyzed in terms of unconfined

compressive (UC) tests. It is hereby noted that other tests such

as California Bearing Ratio (CBR) [10,11], triaxial (confined and

unconfined), resilient modulus, and cyclic wet dry tests are also valid

tests to investigate the performance of the stabilized soils. However,

for a rapid screening of stabilizers, the UC test was preferred. In this

investigation, the compacted stabilized sandy soil samples were

‘cured’ under controlled temperature and humidity conditions

before the soaked and un soaked unconfined compressive strength

(UCS) tests were performed.

Material and Method

Materials Used

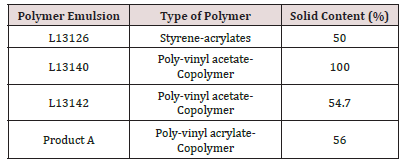

Four different kinds of stabilizers were used in this study, three

polymer emulsion type namely: L13126, L13142 and Product A

and one powder polymer type namely: L13140. Table 1 lists the

polymer type and solid content of individual emulsion type, which

was obtained by drying a known weight of emulsion in the oven

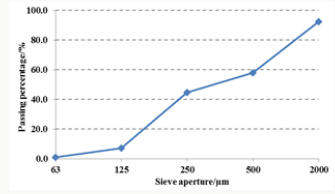

at 1050C to a fixed weight. The sandy soil samples which contain

10% china clay and 90 % sand were considered which more or less

represent a dust prone unpaved soil road. The sand used in this

research is natural sand in Netherland, the gradation is showed in

Figure 2.

Specimens Preparation

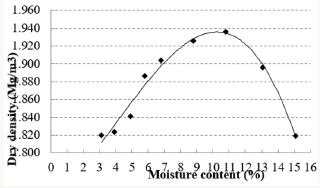

In order to perform compression tests, cylindrical specimens of

100 mm diameter and 150 mm height were prepared. The optimum

moisture content of the sandy soil without stabilizer was measured

by the modified proctor method (ASTM D1557). Figure 3 shows

the result of modified proctor test. From the plot of the Figure 3, it

can be observed that the optimum moisture content of this sandy

soil is about 10.3%. With the known optimum moisture content

and the known maximum dry density of the sandy soil, gyratory

compactor was utilized (at 600kPa vertical stress, 30 gyrations/ min and

1.250 tilt angle) for the preparation of specimens. In order

to mix the polymer stabilizer and soil uniformly, the stabilizer

concentrate was diluted in the water before putting it into the

sandy soil mixture. The dilution ratio was based upon the optimum

moisture content and the amount of stabilizer used. For providing

enough space for the polymer concentrate in the soil matrix, the

stabilizer amount and the amount of water to be added is calculated

on the basis of the optimum moisture content i.e. 10.3%. The

actual density of polymer emulsion was assumed to be 1Kg/L. The

preparation of sample was carried out in following six steps: soil

preparation, additive preparation, soil-additive mixing, moulding,

compaction, curing. The soil was mixed for five minutes before the

addition of dilution. The amounts of added stabilizer were 14L/m3

(i.e. 1 m3 compacted soil contains 14L stabilizer concentrate), 19L/

m3 and 24L/m3 respectively. The dilution ratio was calculated by

the following equation:

where: R: dilution ratio

x: optimum water content (%)

y: maximum dry density of soil (Mg/m3)

z: amount of adding polymer (L/m3)

ρ: the density of stabilizer in the test temperature (Mg/L)

Assuming the depth of penetration in pavement to be 15 cm,

the amount of addition of stabilizer i.e. 14L/m3, 19L/m3, 24L/m3 is

equivalent to 2.1L/m2, 2.85L/m2, 3.6L/m2 respectively. After the soil

and additive preparation steps, the dilution was mixed with sandy

soil by using rotary mixer, until a uniform mixture was achieved.

The specimen was prepared by using a gyratory compactor mould

of 102 mm diameter and 254 mm height. The material was placed

in three layers in the mold and each layer was compacted with rod

for 25 times in order to get a uniform specimen. After molding step,

the sample was placed in the gyratory device and compacted until

the height of the sample was reduced to 150 mm. The compacted

sample was then extruded from the gyratory mould by the

hydraulic jack extrusion device mounted on the gyratory machine.

The compacted sample was then placed in the curing room at 200C

and 40 percent relative humidity. In order to simulate the field

condition, air-dried curing process was used. Each sample was

weighed after 3 days, 7 days, 14 days, 21 days, and 28 days to get

the moisture loss rate.

Unconfined Compression Test

The sandy soil samples stabilized with the different type and

number of additives were tested by using unconfined compression

(UC) setup under soaked and un soaked conditions. In the soaked

UC test, the dry sample was placed in the 25 mm deep water bath

for 15 minutes and after removing it from the water it was drained

for 5 minutes. Then the soaked samples, as shown in Figure 4, were

tested. The soaked UC test reflects the influence of moisture on the

strength reduction of the stabilized soil in the field condition.

Permeability Test

Permeability test was conducted to evaluate the capability of

the stabilized soil samples to allow the water pass through it. The

falling water head setup, see, is used for measuring permeability

of the sandy soil samples with different types and amounts of the

additives. In this test a sample is connected to a standpipe which

provides both the water head and the means of measuring the

quantity of water flowing through the sample. The permeability

value is calculating by using the following formula:

Where: Kt: permeability(m/s)

a: cross section area of used manometer tube (cm2)

A: cross section area of sample in permeameter cell (cm2)

t: measured time interval (s)

L: length of sample (cm)

h1: start level manometer tube distance above overflow level

(cm)

h2: end level manometer tube distance above overflow level

(cm)

The parameters a, A, L were calculated on the basis of geometry

of the samples and the manometer tube. The test was carried out

after the sample was fully saturated. After that, the water tube is

filled to a prescribed starting level h1. After t seconds, the water head level 2 in the manometer tube is recorded. By using the

equation mentioned above the permeability Kt is calculated. The

procedure is repeated at least three times interval until the Kt value

is constant.

Results and Discussion

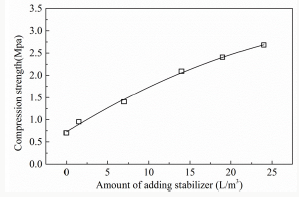

Optimal Polymer Adding Amount

Preliminary test was conducted to get a reasonable amount of

stabilizer quantity to be investigated, L13126 polymer was taken as

an example, various additive amounts of 0L/m3 (pure water), 1.5L/

m3, 7L/m3, 14L/m3, 19L/m3 and 24L/m3 stabilizer quantity were

examined. Figure 5 shows a plot of the additive amount versus UCS

results after 28 days curing. As shown in Figure 5, the compression

strength increases with stabilizer adding amount, it is expected that

higher polymer content leads to thicker polymer matrix and more

interaction between the soil particles, the compression strength

increase almost linearly. It is hereby defined that “incremental

strength” means the UCS of stabilized sample deducted by the

UCS of samples with pure water. According to the Netherlands

specification, the minimum UCS of bounded base layer shall be not

less than 2MPa. Therefore, in this investigation, the incremental

UCS value of 2 MPa was set as our minimum strength requirement.

As can be seen from the prediction curve of Figure 5, the stabilized

soil with 19L/m3 additive amount can reach 2 MPa. Therefore, the

additive amount around 19L/m3 i.e. 14L/m3 and 24L/m3 and at

19L/m3 were investigated in the new test plan for all the polymer

stabilizers.

Polymer Adding Amount Effect

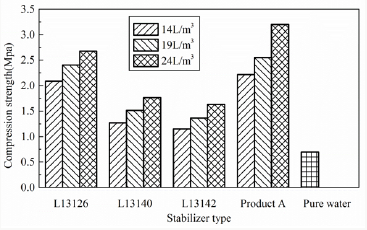

Figure 6 presents the UCS of sandy soil sample stabilized with

different type and different adding amount after 28 days curing

period. All the stabilized sandy soil demonstrated remarkable

increase in UCS than the sample mixed with only pure water. The

highest UCS value after 28 days curing period was found for Product

A stabilized sandy soil which was higher than the sample stabilized

by L13126. The L13140 and L13142 stabilized sandy soil show

almost similar UCS values. However, as compared to the L13126

and Product A, these two stabilizers display lower UCS values. It is

also noted hereby that UCS value increased with the increase in the

stabilizer adding amount.

Wet and Dry Condition Effect

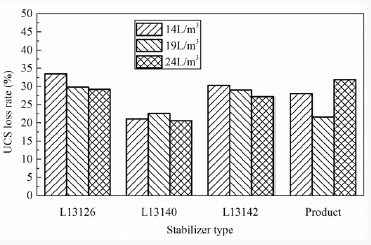

The soaked UCS of the sandy soil samples with pure water

were not able to be tested because the samples disaggregated

in the water bath. For comparison of moisture sensitivity of the

samples, the strength loss rate of different stabilized samples was

determined as Figure 7 In general, it can be observed that the

strength loss rate decreases with the increase in the stabilizers

amount, it indicates the thicker polymer coating will prevent

moisture diffusion better. L13140 powder polymer specimens

provide better water resistance to moisture deterioration and lose

about 20% compression strength, the compression strength loss

rate of others stabilizer specimens is about 30%. The specimens

without stabilizer begin to disintegrate when they are placed in the

water, and then lose load bearing capacity, the polymer can improve

the water resistance of sandy soil.

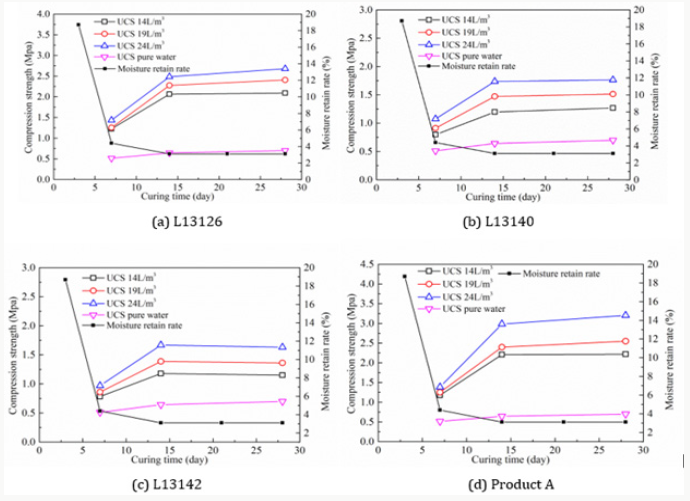

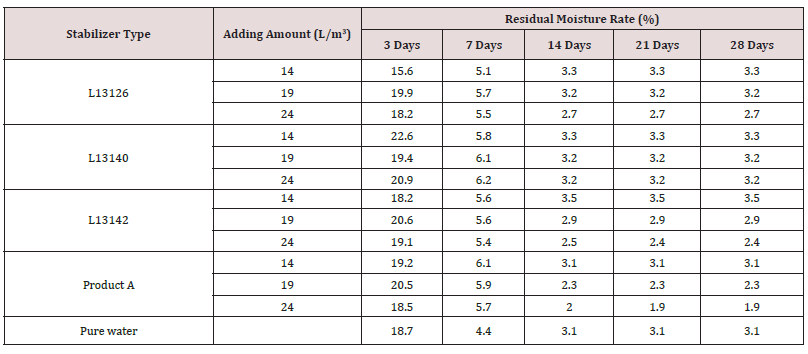

Curing Time and moisture lose effect

The effect of curing time on residual moisture rate is presented

in Table 2, the value is based on the original water adding weight

and the water loss weight. The samples were weighted after 3, 7, 14, 21

and 28 curing days, as shown in Table 2, the residual moisture

rate became a constant, almost all the moisture has evaporated by

the 14th day of curing for all the stabilizer specimens with different

adding amount, the final value is not zero duo to the moisture loss

in the mixture process. Comparing the values of specimens with

stabilizer and pure water, the different is slight, it illustrates polymer

do not affect the moisture evaporation. The moisture evaporates

from the sample that will enhance the bonding between polymer

and soil particles, the relation between compression strength

and residual moisture rate are shown in Figure 8, duo to residual

moisture rate decrease with curing time for all the specimens is

similar, for brevity, the residual moisture rate result of pure water

sample is taken as an example to compare with the compression

strength variation. The sample with polymer stabilizers develop

approximately 60% of the 28 days compression strength within the

first 7 days of curing, however, the strength growth after 14 days

curing period is not significant, the strength growth trend is similar

to that of residual moisture rate decrease, this indicates that the

gain in strength of the stabilized sample may only be related to the

rate of moisture evaporation and not to any chemical reaction as

normally observed in cementitious stabilized products.

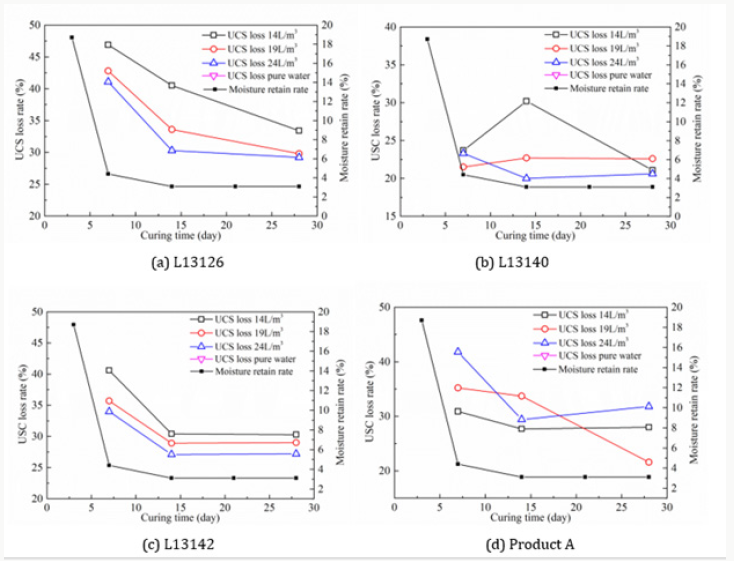

The moisture in the stabilized sample will influence the soaked

UCS loss rate, the effect of curing time on USC loss rate is shown in

Figure 9. In general, the USC loss rate decrease with the increase

of curing time, the trend is similar to that of strength growth,

it illustrates the sample with less moisture inside has a better

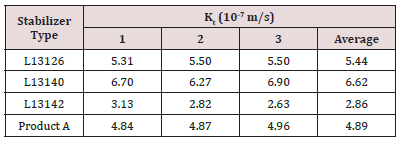

moisture damage resistance. Samples utilized for permeability test

were prepared in the same method as the ones used in the UC test

(refer to “Specimens preparation” section). As shown in Figure 10,

sample is kept inside the tube with no side flow allowed and the

bottom 2 cm of the sample is utilized to apply silicon glue. After

filling up the tube with water the test equipment is left for one day

to be able to fully saturate the sample. The permeability test was

carried out on the samples stabilized by L13126, L13140, L13142

and Product A with 19L/m3 additive amount, 3 replicates for

each case, the permeability results are presented in the Table 3. It

can be observed that all the sandy soil samples stabilized by the

polymer stabilizers show lower permeability which is important

for pavement surface layer to prevent rain water infiltration into

the deeper part of the road foundation, soil stabilized by L13142

show highest permeability.

Implication and Discussion

Polymer is an environmental way for dust control and soil

stabilization, as important as dust control, the mechanical and

hydraulic property are also key points of polymer application, in

this paper, mechanical and hydraulic property include three key

indexes: UCS, soaked UCS loss rate and permeability, after 28 curing

days, the moisture evaporate from the stabilized soil, the specimens

become stronger and have a lower UCS loss rate. Unfortunately,

there are no significant relation between the three indexes for all

the polymers, the highest UCS is product A, the lowest UCS loss rate

is L13140, and the lowest permeability is L13142, therefore it is

hard to find a polymer with higher UCS, lower UCS loss rate and

lower permeability, for the application, field condition, strength

requirement and cost should be considered for stabilizer selection.

Conclusion

This paper in detail describes a quick and easy way, from

sample preparation stage to experimental tests, to evaluate the

performances of four kinds of stabilizers on sandy soil. With the

results obtained from the tests one can examine the relative

performances of various stabilizers. Such tests can be performed

during product development phase itself. For example, from all the

samples examined, tests results indicated that soil stabilized by

L13126 has higher UCS both in soaked and un soaked conditions

than the one stabilized by L13140 and L13142 and it is comparable

to market ready Product A. The 28 days UCS of sandy soil samples

stabilized by using 19L/m3 of L13126 and Product A can reach

to a desired value of 2 Mpa (as per recommendation). Sandy soil

stabilized by polymer powder L13140 is slightly stronger than the

one stabilized by the polymer emulsion L13142. Such information

can be used in the ranking of various products. Other findings

that can be drawn from the results presented in this paper are

summarized as follows.

a) This study shows that the strength of the stabilized sandy

soil is significantly increased both under wet and dry conditions

by using the polymer additives.

b) The UCS values of the sandy soil samples demonstrate

that the polymer-stabilized soil properties improve with the

curing conditions and the additive amount.

c) The increase in strength is observed due to the deposition

of the solidified polymer components after water evaporates

from the emulsion. The amount of polymer deposited on the

surface of the soil particle depends on the concentration of the

polymer and to the degree of mixing.

d) The compressive strength growth rate of the stabilized

soil correlates with the moisture loss rate in the sample. There

is no further strength increase when sample completely loses

its moisture.

e) After 14 days, most stabilized soil samples reach the

maximum compressive strength.

f) As compared to the cement & lime stabilized soil in

literature, the stabilized soil sample shows higher deformability.

g) Sandy soil sample stabilized by the polymer stabilizers

show lower permeability.

Follow on Linkedin : https://www.linkedin.com/company/lupinepublishers

Follow on Twitter : https://twitter.com/lupine_online

No comments:

Post a Comment

Note: only a member of this blog may post a comment.