Lupine Publishers | Journal of Organic and Inorganic Chemical Sciences

Abstract

Three-dimensional printing (3DP) enables the development of diverse geometries through computer aided design using different techniques and materials for desired applications such as pharmaceutical drug delivery medicine. The FDA approval (2015) of printed-medicine opens up an unprecedented opportunity for the discovery of new compounds and technologies for the pharmaceutical industry development. This report shows some advantages, limitations, challenges and perspectives in concerning to 3DP of pharmaceutical grade formulations and polymers used for drug delivery systems.

Introduction

Drug delivery refers to approaches, systems, technologies and formulations for transporting a pharmaceutical compound in the body as needed to safely achieve its desired therapeutic effect. The concept of drug delivery has greatly evolved over the years from immediate-release oral dosage forms to targeted-release drug delivery systems. Indeed, the necessity of controlling the drug release profile to modulate the absorption, the distribution, the metabolization and the elimination of the drug rapidly appeared as a key factor for improving product efficacy and safety as well as to increase the compliance of the patients [1]. In the drug delivery area, versatile therapeutic systems intended to yield customized combinations of drugs, drug doses and release kinetics have drawn increasing attention, especially because of the advantages that personalized pharmaceutical treatments would offer [2].

Three dimensional printing (3DP) technology is a novel technique for rapid prototyping, which constructs solid objects by deposition of several layers in sequence. The introduction and application of 3D printing have promoted enormous innovations in many diverse fields, including aerospace industry, architecture, tissue engineer, biomedical research and pharmacy. It seems that 3D printing technology will lead a new epoch of the next industrial revolution based on its versatility and diversity. Along with development and progress in science and technology, the 3D printing technology gets mature enough so that anyone can apply it with open-source software at a relative lower material cost [3]. The recent introduction of the first FDA approved 3D-printed drug has fuelled interest in 3D printing technology, which is set to revolutionize healthcare. Since its initial use, this rapid prototyping (RP) technology has evolved to such an extent that it is currently being used in a wide range of applications including in tissue engineering, dentistry, construction, automotive and aerospace. However, in the pharmaceutical industry this technology is still in its infancy and it's potential yet to be fully explored [4].

3DP is gaining increasing attention in pharmaceutical formulation development as an effective strategy to overcome some challenges of conventional pharmaceutical unit operations. For instance, the conventional manufacturing unit operation involving milling, mixing, granulation and compression can result in disparate qualities of the final products with respect to drug loading, drug release, drug stability and pharmaceutical dosage form stability [5,6]. 3D printing technology has enabled unprecedented flexibility in the design and manufacturing of complex objects, which can be utilized in personalized and programmable medicine [7]. In this report are shown some advantages, limitations, challenges and perspectives of 3D printing in the elaboration of drug delivery systems.

Advantages and Limitations

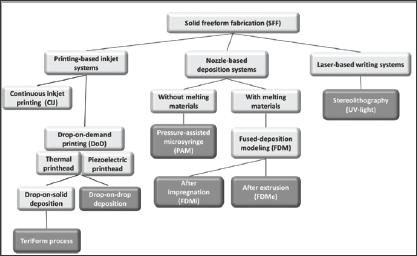

Various techniques for 3D printing, such as fused deposition modeling (FDM), binder deposition, inkjet printing, material jetting, powder bed fusion, photopolymerization, pen-based 3D printing and molding, have been reported in the literature [8,9]. Fused Deposition Modeling (FDM) 3D printing has been recently attracted increasing research efforts towards the production of personalized solid oral formulations. However, commercially available FDM printers are extremely limited with regards to the materials that can be processed to few types of thermoplastic polymers, which often may not be pharmaceutically approved materials nor ideal for optimizing dosage form performance of poor soluble compounds [10]. Such a technique holds huge potential for the manufacturing of pharmaceutical products and is currently under extensive investigation. Challenges in this field are mainly related to the paucity of adequate filaments composed of pharmaceutical grade materials, which are needed for feeding the FDM equipment [11] (Figure 1).

Figure 1: Schematic view of the different 3DP techniques used to fabricate drug delivery systems.

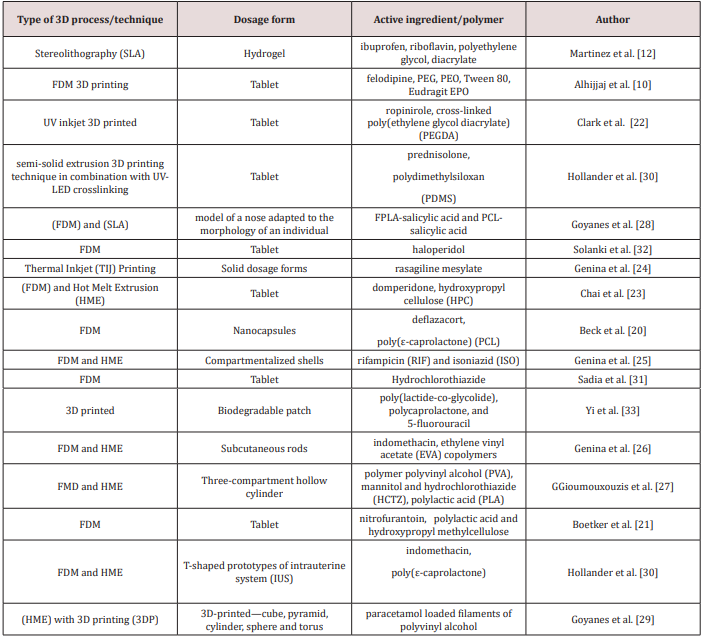

Source [12] From the many types of 3DP available, stereolithographic (SLA) printing offers the unique advantage of being able to fabricate objects by cross-linking resins to form networked polymer matrices. Because water can be entrapped in these matrices, it is possible in principle to fabricate pre-wetted, drug-loaded hydrogels and devices [13].

Table 1: Current 3DP technologies and pharmaceutical formulations for drug delivery.

More information in concerning to these technologies and pharmacology is present in the studies of Jassim-Jaboori & Oyewumi (14), Konta et al. [15], and Mauvi et al. [16].

Challenges and Perspectives

The technological advancements in the pharmaceutical field are constantly improving and provide various possibilities for meeting the needs of personalized drug therapy. The three-dimensional (3D) printing technology has endless potential in the fabrication of patient-specific drug delivery devices (DDD) and dosage forms as the technological development is progressing. Moreover, the rapidly evolving research on 3D printed DDD has enabled.com to determine several challenges related to the manufacturing and marketing of personalized drug delivery systems. The 3D printing has enabled the fabrication of prototypes of DDD with varying complexity and shows that customization of drug products is possible. There is potential to improve patient-specific drug therapies of the future using printing technologies. The technological advancements, new scientific concepts, interdisciplinary work and defined regulatory guidelines will continue to support and strengthen the prospects of 3D printing as an option in the manufacture of medical products [17]. Three-dimensional printing (3DP) is a unique prototyping technology that has advanced over the past 35 years and has the great potential to revolutionize the field of drug delivery with its inherent advantages of customizability and the ability to fabricate complex solid dosage forms with high accuracy and precision. 3DP can fabricate solid dosage forms with variable densities and diffusivities, complex internal geometries, multiple drugs and excipients. 3DP can successfully address the issues relating to the drug delivery of poorly water-soluble drugs, peptides, potent drugs and the release of multi-drugs, etc. However, there are some problems that restrict the applications of 3DP in commercial market, such as the selections of suitable binders, excipients and the pharmaco-technical properties of final products. Further advancement in process performance is required to overcome these issues where 3DP technology can be successfully combined with novel drug delivery system (NDDS) [18].

3D printing encompasses a range of differing techniques, each involving advantages and open issues. Particularly, solidification of powder, extrusion, and stereo lithography have been applied to the manufacturing of drug products. The main challenge to their exploitation for personalized pharmacologic therapy is likely to be related to the regulatory issues involved and to implementation of production models that may allow to efficiently turn the therapeutic needs of individual patients into small batches of appropriate drug products meeting preset quality requirements [19].

Three-dimensional printing has become a useful and potential tool for the pharmaceutical sector, leading to personalized medicine focused on the patients' needs. It offers numerous advantages, such as increasing the cost efficiency and the manufacturing speed, since a rapid prototyping (RP) can be done in a matter of minutes. However, there is still a significant barrier to ensure that 3D printed medicines have the same efficacy, safety, and stability as the pharmaceuticals conventionally manufactured by the Pharmaceutical Industry. Regarding the establishment of guidelines, laws, quality systems and safety of use and consumption of 3D printed medicines, it is a great challenge for the regulatory authorities entailing great obstacles, given the traditional requirements by the pharmaceutical sector [13].

The use of various types of printing technologies offer potential solutions for personalized medicine and tailored dosage forms to meet the needs of individual treatments of the future. Many types of scenario for printed dosage form exist and the concepts include, on the simplest level, accurately deposited doses of drug substances. In addition, computer design allows endless opportunities to create suitable geometries with tailored functionality and different levels of complexity to control the release properties of one or multiple drug substances. It will take some time to convert these technological developments in printing to better treatments for patients, because challenges exist. However, printing technologies are developing fast and have the potential to allow the use of versatile materials to manufacture sophisticated drug-delivery systems and bio functional constructs for personalized treatments [20].

3D printing technology can handle complex internal structure such as internal walls, hollow channels, porosity, multiple material regions and multiple drug distributions. This is a feature traditional pharmaceutical manufacturing processes do not share, which ensures feasibility of realizing rapid release, sustained release, controlled release, multiple drug delivery system and personalized medicine based on structure design [21]. Indeed, drug delivery from 3-dimensional (3D) structures is a rapidly growing area of research. It is essential to achieve structures wherein drug stability is ensured, the drug loading capacity is appropriate and the desired controlled release profile can be attained. Attention must also be paid to the development of appropriate fabrication machinery that allows 3D drug delivery systems (DDS) to be produced in a simple, reliable and reproducible manner [22].

Findings

It is evidenced that through its versatility, speed of production and precision, the use of three-dimensional printing for the elaboration and distribution of controlled drugs plays a key role in the current pharmaceutical industry, considering that drugs can be designed according to the patient's need. The fused deposition modeling (FDM) technique and hot melt extrusion (HME) of filaments for 3DP still excels in relation to the other printing techniques, such as binder deposition, inkjet printing, material jetting, powder bed fusion, photopolymerization, pen-based 3D, printing and molding have been gaining more and more space. The use of3DP in pharmaceutical formulation development is an effective strategy to overcome challenges of conventional pharmaceutical unit operations, since the conventional manufacturing operation can result in disparate qualities of the final products with respect to drug loading, drug release, drug stability and pharmaceutical dosage form stability. 3DP offers significant potential benefits in the field of drug delivery and pharmaceutical/medical device manufacture.

Read More About Lupine Publishers Journal of Chemistry Please Click on Below Link:

https://lupinepublishers-chemicalsciences.blogspot.com/

No comments:

Post a Comment

Note: only a member of this blog may post a comment.