Lupine Publishers| Journal of Civil Engineering and its Architecture

Abstract

Agricultural is the largest employment sector of Bangladesh and most of the people earn their living from agricultural production. The magnitude of agricultural production varies spatially as agricultural production depends on topography, the fertility of the land, availability of river, availability of marketing place, input and so on. The intent of our study is to regionalize all the 64 districts of Bangladesh based on Boro production, fish production and the number of growth center and to analyze the impact of it on rural development. To do so, the data are collected from the Bangladesh Bureau of Statistics (BBS), the composite index method was employed to analyze the data. The data reliability is checked through statistical parameters named level of skewness, kurtosis and standard error of the mean. Then acquired data is classified by using the mean standard deviation method, equal class interval method and the arithmetic mean method. Comparing the three histograms it is found that equal class interval method has more symmetrical shape, hence more normally distributed. Results show that most of the areas are moderately producing the agricultural product. The findings of this study can be used to find out the location which can be best suited for the agricultural industry.

Keywords: Optimum Bitumen Content; Optimum Fly Ash content; Stone Dust; Water Effect

Abbreviations: AASHTO: American Association of State Highway and Transportation Officials; BS: British Standard; CA: Coarse Aggregate; FA: Fine Aggregate; MF: Mineral Filler; OBC: Optimum Bitumen Content; Va: Voids in total Mix; VMA: Voids in Mineral Aggregate; VFB: Voids Filled with Bitumen

Introduction

The surface coarse of flexible pavement normally comprises of coarse aggregate, fine aggregate and filler heated to suitable temperature, mixed thoroughly with heated bitumen at required viscosity and then compacted [1]. One of the major concerns of mix design of bituminous mix is the type and amount of filler used which may affect the performance of the mix. Various studies have been conducted to study properties of mineral filler, generally the material passing 0.075mm IS sieve, to evaluate its effect on performance of asphalt paving mix in terms of consistency, void filling, Marshall Stability and mix strength. Fly ash is one of the major wastes by products of coal based thermal power station [2-5]. This waste is mostly disposed by coal-based thermal power plant in the form of refuse in piles and behind embankment type retaining structures. At present, with the expectation of small scales underground waste disposal operations in abandoned coal mines, most of this waste is disposed at the surface which inevitably requires excessive planning and control of minimize the environmental impact of mining. It also results in non-productive use of land, air and water pollution, possible failure of waste embankments and loss of aesthetic value of the land.

In recent years various research studies on fly ash have been conducted to analyze the possibility of utilization of these ashes. Hence, in this study, an attempt has been made to explore the use of fly ash passing 0.075mm sieve and has been considered to be filler in bituminous paving mixes by studying various fundamental engineering properties [6]. In recent years various researches have been conducted to use fly ash as mineral filler in bituminous mix design. Sankaran and Rao [7] made a comparison of fly ash with other fillers. They pointed out that fly ash at 2% filler content provided the highest stability among the other filler. Henning [8] investigated the effect of a class C fly ash on asphalt mixture properties and concluded that the addition of 4% fly ash resulted in the higher stability and flow but ended up with low air voids. Rosner et al. [9] used fly ash as mineral filler and anti-stripping agent for asphalt concrete mixtures and showed that retained strengths of samples increased as additional fly ash was used in the prepared mixtures.

Tapkin. showed that fly ash can be used effectively in a densedgraded wearing course as a filler replacement. Konstantin et al. studied on feasibility of fillers in asphalt concrete using two different binders. These binders were fully blended with filler materials i.e. fly ash, lime and cement [10]. The study result demonstrated that rheological properties of the asphalt were greatly improved with the addition of these fillers. Fly ash also appears in improving the aging resistance of mastics. With the addition of fillers, compatibility of mixtures was not affected Kar et al. represented the influence of fly ash as a filler as a filler in bituminous mixes that the mixes with fly ash as filler exhibits marginally inferior properties compared to control mixes and satisfy desired criteria specified by a much higher margin. They recommended to utilize fly ash wherever available, not only reducing the cost of execution, but also partly solve the fly ash utilization and disposal problem. Uddin and Supriya studied the influence of fillers on paving grade bitumen and observed that fly ash being a waste product can be effectively used as filler to improve the properties of bituminous mix and fly ash also being cost effective as compared to cement and lime.

Materials & Methodology

Materials Used

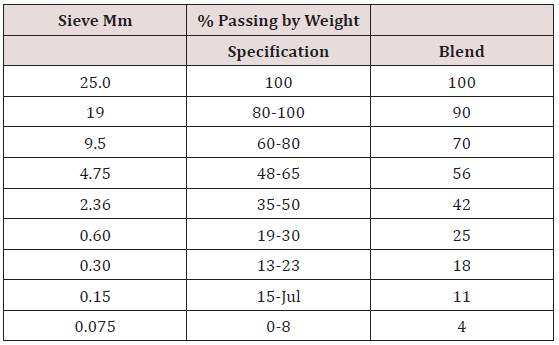

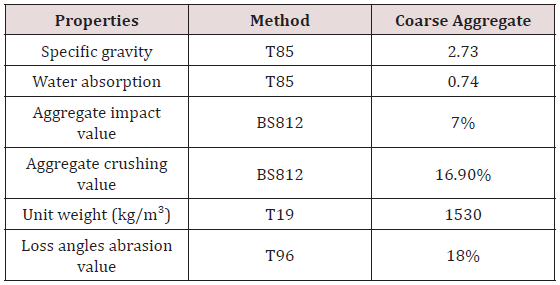

Aggregate: In the laboratory test program, black stone chips which are smaller than 25mm and larger than 2.36mm in size were regarded as coarse aggregate. The black stone used in this investigation was collected from construction site of architecture building of RUET. Aggregate gradation and physical properties of coarse aggregate are shown in Tables 1 & 2 respectively. The coarser sand smaller than 2.36mm and larger than 0.075mm in size were used as fine aggregate combination of domar sand and Padma river sand were used as the main source of fine aggregate. Specific gravity of fine aggregate was found to be 2.65. Two types of filler, stone dust and fly ash which is finer than 0.075mm in size a used in this investigation. Stone dust is used as standard filler for this project. Fly ash used for main purpose were collected from Barapukuria Coal Power Plant, Dinajpur. Here specific gravity of fly ash and stone dust were found to be 2.44 and 2.13 respectively [11].

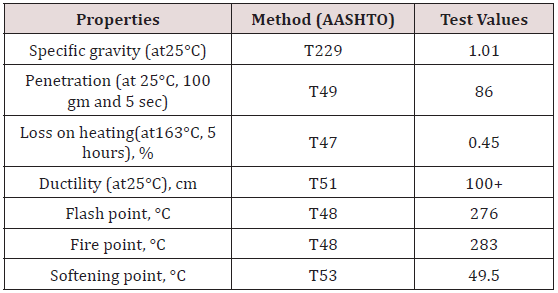

Bitumen: Grade of 80/100 bitumen has been used as bitumen for preparation of bituminous mixture. The important physical properties are tabulated in Table 3.

Methodology

At first the test procedure introduced by Bruce Marshall and developed by the U.S Corps of Engineers was applied to find optimum bitumen content using stone dust as standard filler for medium traffic condition. This test has been fundamentally used in this study to evaluate the different mixture at different bitumen contents and the parameters considered are stability, flow value, unit weight, air voids, voids in mineral aggregates, voids filled with bitumen. Now by fixing this optimum bitumen content specimens were prepared. Specimens prepared by replacing stone dust with fly ash gradually such as 0% fly ash and 100% stone dust, 25% fly ash and 75% stone dust, 50% fly ash and 50% stone dust, 75% fly ash and 25% stone dust and 100% fly ash and 0% stone dust by total weight of filler. Bruce Marshall test was applied to determine optimum fly ash content by Marshall Mix design criteria for medium traffic condition [12]. Now using these optimum bitumen content and optimum fly ash content specimens were prepared to observe the effect of water submergence on compacted specimen. To observe the effect of water submergence on compacted specimen, compacted specimens were submerged in water for 0, 5, 10, 15 and 20 days. After each selected days Marshall Test was applied on these specimens.

Result and Discussion

Marshall Test of Specimens Using Stone Dust as Filler

For Bituminous mixes using standard filler stone dust and various bitumen content following six curves showing the relationships of unit weight, Marshall stability, flow, percentage of voids in total mix, percentage of voids in mineral aggregates, percentage of voids filled with bitumen with percentage of bitumen content were drown to determine optimum bitumen content. Curves were drown with data from Table 4. Curves are shown in Figures 1-6. Here, Optimum bitumen content from above figure calculated as 5.56%. Value of Stability, flow, %Va, %VMA and %VFB for optimum bitumen content satisfy the Marshall Mix Design Criteria.

Read More About Lupine Publishers Journal of Civil Engineering and its Architecture Please Click on Below Link: https://lupinepublishers-civilengineering.blogspot.com/

No comments:

Post a Comment

Note: only a member of this blog may post a comment.