Lupine Publishers| Journal of Textile and Fashion Designing

Abstract

The 60’s cooling collagen viscose rayon blended yarn was fabricated by using ring spinning system. The blended yarn constitutions included 50wt% of regular viscose rayon with 1.5d and 38mm, 35wt% of cooling viscose rayon with 1.25d and 38mm, and 15 wt% of collagen viscose rayon fibers with 1.5d and 38mm. As mension above 60’s cooling collagen viscose rayon ring yarn was used as filling yarn. The 60’s Model Rayon(60wt%) ring yarn was used as warp yarns. The grey cloth specifications included warp density 198 ends/ 2.54cm and filling density 146 picks/2.54cm as well as the fabric width is 170cm which was produced by Picanol air-jet shuttleless loom. From the experimental results, the finished woven fabric was fabricated throuth souring, bleaching, dyeing, finishing, and heat setting processes. The color fastness of woven fabrics with high-count and cooling collagen achieved grade 4-5 according to CNS1494 testing standard.

Furthermore, the Functional Properties of Finished Woven Fabric were Processed as Follows

The instant cooling feeling value (Qmax) achieved 0.206W/cm= according to CNS 15141 testing standard. The static thermal image temperature difference achieved 1.3℃ according to FTTS-FA-010 testing specification which was draw up Functionality and Industrial Textiles Certification and Verification Review Committee in Taiwan. The Anti-pilling achieved grade 4 according to CNS 15141 testing standard. The electrostatic voltage caused by friction achieve grade 2 (100≤V< 500). The woven fabrics with highcount and cooling ccollagen blended yarn can be used in bedding, shirts, jackets, scarves, pants, pajama, etc.

Keywords: Cooling collagen viscose rayon ring blended yarn; Instant cooling feeling (Qmax); Static thermal image temperature difference; High count woven fabric

Introduction

The development, manufacture and design of Taiwan’s functional home bedding fiber products, main problem lies in the functional design of the bedding fiber products, fashion design, cost assessment and comfort. The advantages of cotton fiber made bedding products include good water absorption and air permeability. However, there are disadvantages of large shrinkage rate and wrinkle after washing. The advantages of polyester fiber made bedding products include not easy to wrinkle and shrink, and high heat resistance, but it is easy to generate static electricity and contaminate dust and has the disadvantage of being stuffy when used. The advantages of cellulose series fiber-made bedding products included better moisture absorption and dyeing, which are suitable for blending with other fibers such as polyester, and polyamide, but it is easy become longer after hanging, easy to shrink after laundry, and dry cleaning is required. The advantages of acrylic fabrics fiber made home bedding products, included nonwrinkle, better chemical resistance, sunlight resistance and thermal insulation, but have the disadvantages of easy raising, worse heat resistance and sultry heat in summer. Especially on the printed cloth, it is not suitable for the strong sunlight. Due to long-term sunlight radiation, it will cause the pattern on the fabric to fade. It is recommended to install it in a cool and ventilated place in the house. The jacquard woven fabric was weaved according to the predesigned pattern, which is visually elegant and textured. Therefore, it is suitable for installation in the bedroom, study, and elder room are also high-priced products. The long-term use of home furnishings and bedding products mainly emphasizes the beauty, style and brand. Due to the problems of comfort and functionality, the development of woven fabrics with high counts of cooling collagen bedding has stagnated and lacks interest. Therefore, the development of this case uses the advantage of blending rayon fibers with cooling collagen fibers to improve the general use of materials such as cotton and polyester to improve the quality, comfort and structural design of the bedding. Improve and declare the quality, comfort and structural design of bedding products, which is the future path for the development of international bedding product market.

In recent years, the collagen is more important in the fields of health food, cosmetics, medicine and man-made fiber. In the field of collagen textile fiber production in recent years, the additive is mainly composed of papolis, collagen extracted from milkfish scales, bone-extracted collagen and artificial collagen [1]. Collagen is a natural substrate in the natural ecology, which has the following three aspects of health effects on the human body.

a) Comfort - collagen is composed of 18 kinds of amino acids, which has excellent biocompatibility with the human body.

b) It has humidity regulation function, because collagen is rich in hydrophilic groups such as many amine groups (-CONH) and amino groups (-NH2), the structure is porous, easy to diffuse water molecules, and can be adjusted in humid air as well as have a certain amount of water.

c) Tryptophan and Tyrosine in collagen absorb ultraviolet rays, and ultraviolet rays are harmful to the skin, so collagen can protect the skin from ultraviolet light radiation [2-7]. The special collagen formula and the polymerization method of the innovative process to enhance the performances of collagen rayon staple fibers such as heat resistance, durability, moisture retention, skin-friendly and comfort, etc., and have higher added value and economic benefits [8].

Experiment

The 60’s cooling collagen viscose rayon blended yarn was spun by ring spinning method. The cooling collagen yarn constitution was made from 50wt% regular viscose rayon, 35% cooling viscose rayon and collagen viscose rayon through ring spinning sytem which through scoutching and opening, carding, combing, 3-passage drwaing, roving, ring spinning, and autocorner processes to fabricate the blended yarn. Furthermore, 60’s cooling collagen viscose rayon blended yarn was used as filling yarn (40wt%) and 60’s Model rayon yarn as the warp yarn(60wt%). The grey cloth specifications included warp density 198 ends/ 2.54cm and filling density 146 picks/2.54cm as well as the fabric width is 170cm and fabricated by Picanol air-jet shuttleless loom. The fabric structure is sateen, weight is 213g/yd and width 157cm (62in).

Results and Discussion

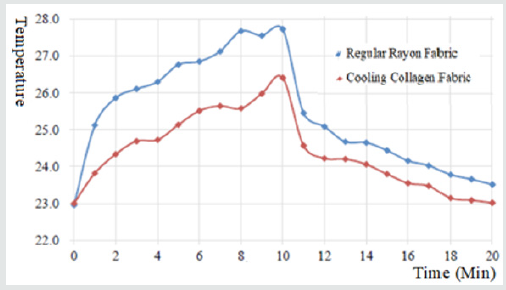

Figure 1: Comparison the thermal absorption and diffusion between cooling collagen and regular knitted fabrics.

The color fastness of woven fabrics with high-count and cooling collagen achieved grade 4-5 according to CNS1494 testing standard. The finished woven fabric passed through souring, bleaching, dyeing, finishing, and heat setting processes. Furthermore, the functional properties of finished woven fabric were processed as follows: Quality specifications in accordance with FTTS-FA-019 testing specification [11], instantaneous cooling value of woven fabric with high count and cooling collagen could be achieved 0.206W/cm2. The static thermal image temperature difference achieved 1.3℃ according to FTTS-FA-010 testing specification [10] which was draw up Functionality and Industrial Textiles Certification and Verification Review Committee in Taiwan. The Anti-pilling achieved grade 4 according to CNS 15141 testing standard. The electrostatic voltage caused by friction achieve grade 2 (100≤V< 500). The water absorption height along warp and filling direction was 59mm and 51mm respectively according to FTTS-FA-004 testing specification [9]. The thermal absorption and diffusion behaviors between cooling collagen and regular woven fabrics was shown in Figure 1. After irradiating by a 500W halogen lamp, there is a tendency to gradually increase the temperature as the irradiation time increases since thermal absorption behavior. The halogen lamp is turned off, after the irradiation for 10 minutes, and the temperature gradually decreases as time increases since thermal diffusion behavior. Furthermore, the higher thermal absorption and diffusion of regular viscose rayon woven fabric than cooling collagen woven fabric, since the lower moisture content and absorption of regular viscose rayon woven fabric than cooling collagen woven fabric. It is probably because the collagen has much more amino acid and hydroxyl functional groups, so the moisture content and absorption ability would be better. Due to superior functionality, physical and chemical properties, the woven fabrics with high-count and cooling collagen staple yarns can be used in bedding, shirts, jackets, scarves, pants, pajama, etc.

Conclusion

The yarns and woven fabrics with high-count and cooling collagen performance was fabricated successfully. The spring and summer bedding used woven fabrics are designed as the product, and the related physical and chemical properties (washing dyeing fastness test- faded and stained, anti-pilling, etc.) and functionality (instant cool heat flow, static thermal image, water absorption height, electrostatic voltage caused by friction, etc). The experimental results show that the physical and functional properties can meet the basic requirements of bedding used woven fabric in spring and summer. The development of spring and summer bedding is in line with the industrial upgrading and transformation and industry innovation research and development theme, including the combination of upstream (functional fiber), midstream (yarn, fabric), downstream (dyeing and finishing) industry and women’s products to integrate cooperated supply chain. The cooling collagen woven fabric has lower temperature than regular viscose rayon fabric. Due to superior functionality, physical and chemical properties, the woven fabrics with highcount and cooling collagen staple yarn could be used in bedding, shirts, jackets, scarves, pants, pajama, etc.

Acknowledgement

Much appreciated to the Industrial Bureau, Ministry of Economic of the Executive Yuan in Taiwan for providing financial support for this project (B10710200). This industrial- academicals project is jointly developed by Dong Chu International Textile Co., Ltd. and Textile and Materials Industry Research Center of the Feng Chia University (TMIRC). During the implementation of this project, we are very grateful to the supply chain manufacturers for their assistance in mass production and finished product design and testing method of woven fabrics. We would also like to thank the students from the Organic and Inorganic Composites Laboratory, Department of Fiber and Composite Materials (FCM) of Feng Chia University (FCU) and the colleagues of TMIRC for their assistance in testing and experiments.

Read More About Lupine Publishers Journal of Textile and Fashion Designing Please Click on Below Link: https://fashion-technology-lupine-publishers.blogspot.com/

No comments:

Post a Comment

Note: only a member of this blog may post a comment.