Lupine Publishers- Environmental and Soil Science Journal

Abstract

In this study, a method of water leakage detection system was investigated using acoustic emission device, AQUA M 300D. It is

used to pinpoint leakage sources for underground pipelines system. The leakage is detected by analyzing the feedback frequency,

where leakage area produces higher frequency due to the vibration resulting from a high-pressure liquid that flows through the

crevice. The method is successful to detect underground pipelines system leakage with 90% accuracy.

Introduction

Every year, the government spends high budget on improving

water pipeline system by doing maintenance, replacing older water

pipeline, and locating leakage area. There are large percentage

of water loss due transportation from sources or treatment plants

to users. Water loss can be attributed by several causes including

leakage, metering error and misuse of public usage [1]. But, water

loss due to leakage contributes a larger percentage [2]. There are

several methods that can be used to detect water leakage. However,

in this study, acoustic emission technique has been chosen as

it is the best non-destructive test for underground water pipelines

[3,4]. The tests of efficiency and compatibility of the technique in

detecting underground water pipelines is explored. This paper will

also discuss the failure analysis that commonly occurs, and the factors

lead to it. The test is conducted at Universiti Pertahanan Nasional

Malaysia.

Instrumentation

Acoustic Detector AQUA M300 D

Figure 1 shows the AQUA M300 D, a multi-purpose detector designed

to allow the user to carry out electro acoustic leak detection

on pipe systems carrying water, acoustic leak detection on pipes,

and to perform non-destructive pinpoint leak detection on pipes

which have previously been flooded with trace gas using the indicative

measurement of different hydrogen concentrations.

Experimental Procedure

Acoustic Detector AQUA M300 D is used to record frequency

readings at the possible leakage locations. Four locations have been

selected, which are pipe located under the road, parking lot, chancellor

building, and Block C4.

Results and Discussions

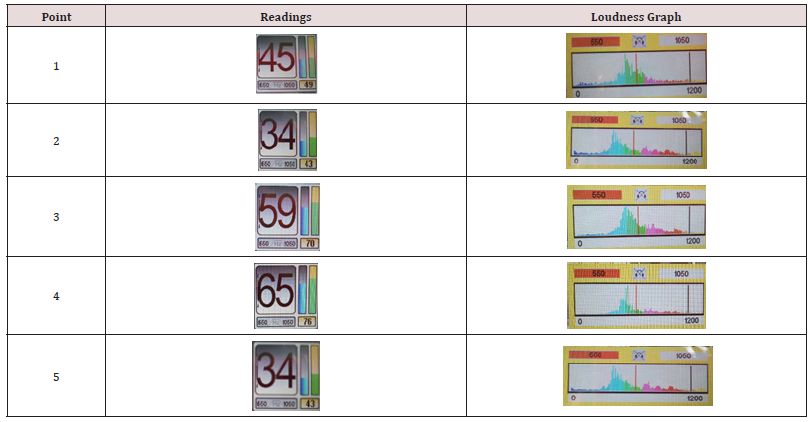

Case Study 1: Leakage from Pipe Located Under the Road

Figure 2 below shows watermark appear on the road surface

due to leakage or crack in underground water pipeline. Five readings

have been taken to determine the sources of the leakage as

shown in Figure 3 The readings are displayed in the (Table 1) From

the table, it shows that frequency reading at point 4 is the highest

compared to other points. The high frequency is emitted due

to occurrence of underground water pipeline leakage or crack. It

is resulting from the vibration that is produced by a high-pressure

water flow through crevice in the water pipeline. The smart bar indicator

will increase when the frequency increases. That indicates

that the range of potential leakage pinpoint is narrowed down. The

area that does not have water pipe shows low reading because

there is no vibration occurred due to water flow.

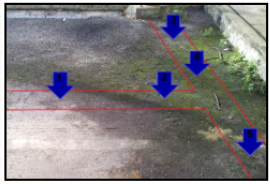

Case Study 2: Wet Surface Detected at the Parking Lot

A wet surface had been detected at the parking lot surface near

the staffs’ residence as shown in Figure 4 The wet surface is obviously

detected during peak hours. This is because during peak hours,

water consumptions are high. So, a higher-pressure force flows in

the underground pipeline thus forces the water escape through the

crevice. The water then is pushed up to the surface through soils

and resulting in wet surface appears on the ground. The readings

are taken from five pinpoints indicated by blue arrows. The red line

shows the underground water pipeline path. The acoustic device

has been used to determine the pinpoint of the leakage. The readings

taken are plotted in Table 2. The results demonstrate that the

leakage is highly possible to occur at point 4 as it shows the highest

frequency reading. This is the result of vibration from water escaping

from the crack or leakage on the pipe. Uniform reading should

be accomplished if the pipeline is in good condition. Point 2 also

shows a high frequency reading though not as high as point 4. It can

be concluded that the frequency increases as the detector comes

close to the source of leakage. The readings at point 1, 3, and 5 are

lower compared to point 2 and 4 as they are further from the leakage

pinpoint.

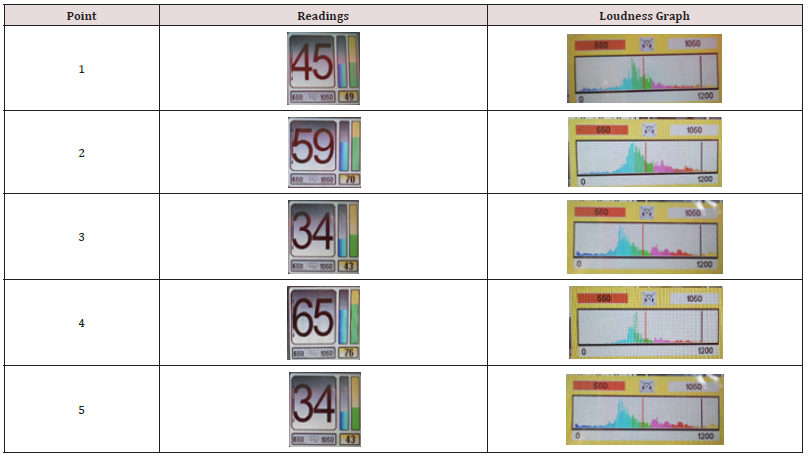

Case Study 3: The Chancellor Building

Watermark is detected at the ceiling of Chancellor Building as

shown in Figure 5 below. Therefore, five frequency readings have

been taken from five different places near the watermark as shown

in Figure 6. Based on the results displayed in Table 3, there are

two possible points of leakage which are at point 3 and 4. This is

because at point 3 and 4, the device detected highest amplitude of

loudness which came from the leakage.

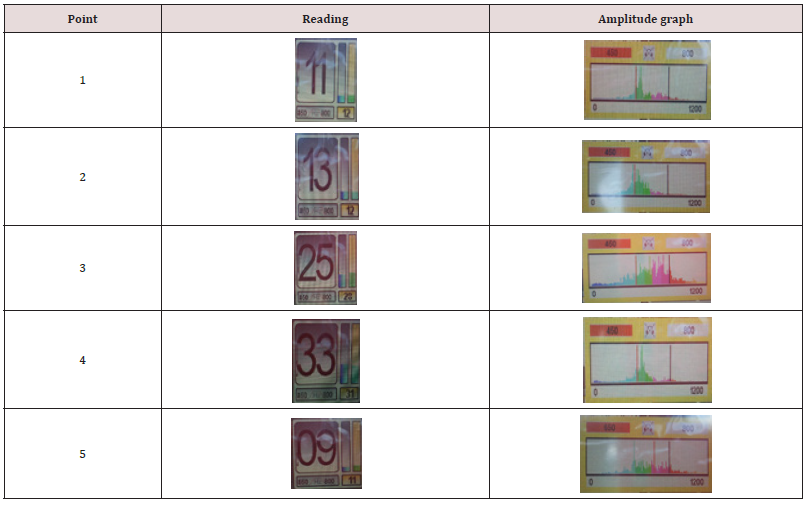

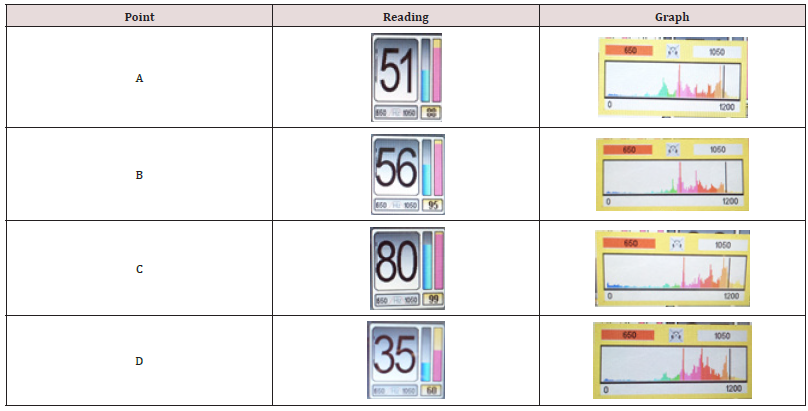

Watermark has been spotted at Block C4 as shown in Figure 7

Points of interest are labelled as shown in Figure 8 to determine

the source of leakage. The results are displayed in Table 4. Based on

the results, the highest frequency reading is obtained at point C followed

by point B, A, and D. This is because water leakage occurred

at that point causing the pipeline emitted a higher vibration that

can be detected by the detector.

Crack Propagation Theory

From the results obtained, we can analyse the factor that leads

to cracks and leakage. Leakage can occur as the results of high pressure

and type of material chosen for pipe. High pressure can cause

stress that leads to propagate cracks. Thus, crack propagation theory

is studied to determine the suitability on pipe selection. Due to

uniformity of loading, an element of the pipe is subjected to normal

stress or hoop stress (σ1) and meridian stresses (σ2) in the longitudinal

direction. Stresses subjected to pipe wall determined by internal

pressure, radius and thickness of the wall and are experienced

by every part of the wall pipe.

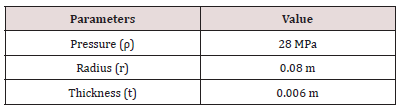

In order to find maximum stress acting on the pipe wall, hoop

stress and meridian stress both need to be calculated. The hoop

stress is the stress that occurs at y-plane direction. Meanwhile meridian

stress is the force acting on x-plane direction. The pipe sample

is shown in Table 5 below.

Calculation of hoop stress: -

σh=pr/t

σh= (28) (0.08)/0.006

σh=373.3 MPa

Calculation of meridian stress: -

σm=pr/2t

σm= (28) (0.08)/2(0.006)

σm=186.67 MPa

From the calculations, the value of hoop stress is chosen as operating

stress. It is chosen because the value of the stress is the maximum

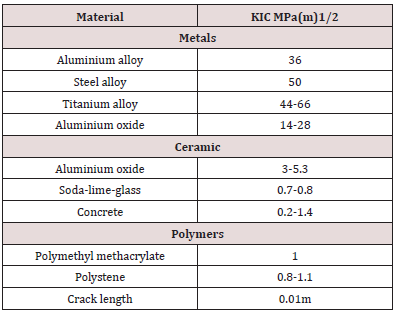

stress experienced by the pipe wall. Fracture toughness, Kic,

is the resistance of a material from fracture starting from pre-existing

cracks. From this equation we can predict the stress state that is

closed to the crack tip accurately. Geometric factor is dimensionless

and determined by geometry, loading configuration (load acting on

pipe), and the ration of crack length to specimen width.

The equation is given as

K=Yσ√πa

Where;

K=stress intensity factor

Y=geometric factor

σ=operating stress=σmax

a=crack length

The stress intensity factor, K is then compared to plane strain

fracture, Kic as stated in the Table 4.4. The Kic is temperature, strain

rate, and microstructure of materials dependant. The magnitude of

Kic diminishes with increasing strain rate and decreasing temperature.

The value of Kic normally increases it with reduction in grain

size as composition and other micro structural variables are maintained

constant [5].

Y = in this shape of crack for pipe, 1.12 is taken for the value of

geometry factor

a = (crack length)/2

= 0.01/2 =0.005 m

K=Yσ√πa

K=1.12(373.3) √ (π (0.005))

K=52.40 MPa√m

From calculation made, stress intensity factors the value, K is

greater than plane strain fracture toughness, Kic as shown in Table

6 This means the crack on the pipe is propagating.

Conclusion

Cracks and leakage detection in buried water pipeline system

at UPNM area was conducted using an acoustic device which is

AQUA M 300D. It is found that the pinpoint of cracks and leakage is

successfully determined without affecting the pipeline. This study

is practical to be used as to detect abnormalities in the underground

water pipeline. A theoretical analysis for stress intensity factor

also has been investigated. The pipe is modelled as a thin wall

cylindrical to calculate the stress acting on the pipe wall. From the

data analysed, it can be concluded that the stress intensity factor, K

should not be greater than plane fracture toughness, Kic of the pipe

material. If the value exceeds, the crack will propagate and lead to

leakage. The theoretical calculation gives agreeable result with this

study as the K value exceeds the Kic, thus resulting in leakage on the

pipeline.

Follow on Linkedin : https://www.linkedin.com/company/lupinepublishers

Follow on Twitter : https://twitter.com/lupine_online

No comments:

Post a Comment

Note: only a member of this blog may post a comment.