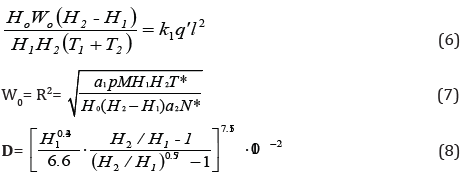

Lupine Publishers- Environmental and Soil Science Journal

Introduction

In recent years, both in the Republic and in the CIS and

far abroad are developing low-intensity stationary systems of

irrigation, consisting of Micro Sprinklers, impulsive actions, aerosol

auto oscillatory action sprinkling irrigation, auto oscillatory action

auto oscillatory action combined, the drip, drip pulsing and a

number of others. This is because low irrigation system has a

number of significant advantages over other methods of irrigation.

Especially promising the creation of automated sprinkling systems

impulse machines, combined, auto oscillatory action stepper

auto oscillatory action rocker type, pulse-airborne apparatus

auto oscillatory action, etc. It should be noted that these systems

allow to reduce the capital cost of their construction, also ensure

the principle as “sprinkling” or “drip” in condition of daily water

use plants. That is to create optimal conditions for the growth and

development of plants during their growing season (Figure 1).

Moves the study

Automated watering crops the basis for high yields and

productivity. Therefore, from the elements and devices used

automatics require reliable and uninterrupted operation. Therefore,

starting from the design stage through these devices and the

production and operation, reliability issues, because the problem

of reliability is not only technical, but also an important economic

task. Reliability theory developed in recent decades, offers a great

opportunity for a qualitative assessment of the reliability of existing

irrigation technique, including micro irrigation systems. Reliabilitythis

property of equipment or system to perform specified functions

to maintain their performance within the required period or time

required. From among the existing irrigation technique, stationary

sprinkling system consisting of a large number of similar elements

in a specific order on the field and required for the irrigation of crops.

Determining the reliability of one of these elements will decide the

reliability of systems. Reliability issues fixed irrigation systems in

particular, equipped with sprinkling installations engaged in many

of the scientists in the former Soviet Union and abroad. To examine

the elements of the calculation on reliability of low-intensity

sprinkling (for example pulse sprinkling auto oscillatory action)

should consider the technological feasibility and sprinkler systems.

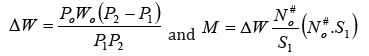

Optimal low irrigation system parameters were determined by us

by searching for the specific functions listed minimum cost with

UD. Depending on the area of the system S; aspect ratio θ; the cost

of the system (Q); Mr pressure corresponding to the pressure

dictating point; conditional irrigation period tat equal i/q 3600

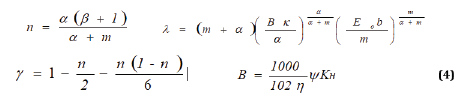

ì where,

m irrigation norm, m; q / -maximum ordinate hydro-module m/s).

Number of distribution pipelines (N); the distance between

irrigation technique (sprinkle plants) l; x factor, equal with the

placement of devices on square 0.2; the length of the i-th pipeline system l(i) its diameter (D)(i) and discharge Q(i) , the coefficients

(k), (m), β -dependent roughness of the internal the surface of the

pipes; costs of irrigation Engineering (sprinkler devices, etc.). With

g and the pressure Sn site; the cost of one kW/h of electricity; ψ,

coefficient η pump unit equal to 0.7 coefficient of non-uniformity

of flow

gde, r- ratio splash start P2 to pressure end splash r1), equal to

1.02-1.25; factor e0 = e1 +e2 (e1, e2 -regulatory factors of efficiency

of capital investments and annual deductions for depreciation and

repairs); coefficients (b), (d) dependent on the material and the

cost of pipe laying and operating costs of the attendants e(n): [1,2]

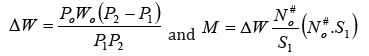

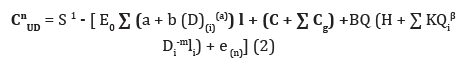

Studies have shown that the most economical option is the

simultaneous operation of all sprinkler devices system, i.e., when

the system is produced by the limit dispersal of current irrigation

[3] in this case has a minimum at points determined by the

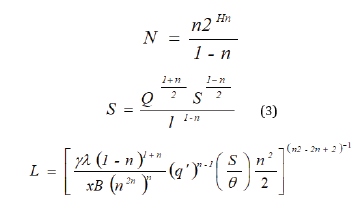

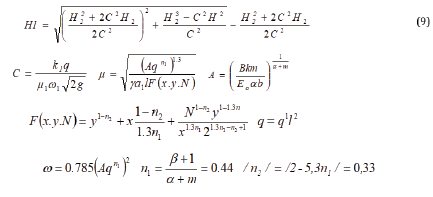

expressions:

Where is

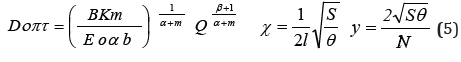

Substituting in the formula (3) and (4) coefficients

corresponding to steel pipelines (d = 1.4; m = 5.1; β= 1.8; K =

0.00107; In = 50; E0 = 0.2; Ton = 1.1), obtain payment formula to

determine and that for ease of use, represented by nomogram

(Figure 2). Similar monograms built and for pipes made of plastics

and other materials. Optimal pipeline diameters (D)opt, I, number

of irrigation pipelines x, suspended from the distribution pipeline,

number of sprinkler devices on the polynom pipeline y define the

following ratios:

If you change the original parameters S, q/, θ, m) within: < = 30

S < = 300 ha, 10 0.3-7 < = q/ < = 1.0 x 10-7 m/s, < 0.25 = θ < = 4, 0.3

< = M < = 1.0 m

1000 m3/HA, the optimal system settings change within: 35 < =

l < = 135 m; 3 < = N < = 65; 1 = < x < = 50; and 1 < = y< = 33. Being

attached to squares, laid down specific natural-economic conditions

define systems parameters of irrigation on low-intensity pulsed

example sprinkling [4]. Consider these square set and equal to 150-

400 ha and have an average optimal relationship of the parties 1-3

and natural-economic conditions irrigation norm 0.35-0.75 m and

a maximum ordinate 0.6 x 10 hydro-module-7 -1.0 x 10-7 m/s.

Averaged source data S= 200 ha, θ = 2; M = 0.55 m, q/ = 0.8

x-7 m/s, the following optimal system settings l= 50m, N= 22, x =

10, y = 8 obtained using the following programs and formulas

(4.5). For other crops and natural-economic conditions these

parameters are defined similarly. Obtained values of N, l, x, y, (D)

opt. I -enable you to define the basic construction and

technological

parameters of irrigation equipment (impulse sprinklers apparatus

self-oscillating action): as head n2, corresponding pressure start

splash RV2, head n1, the pressure end splash r1; constructive

volume pneumatic accumulator W0 and nozzle diameter (D) [3,5].

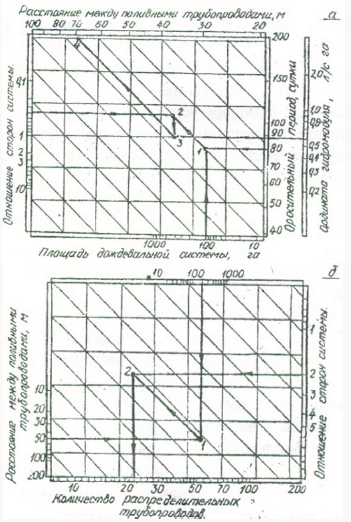

Based on the submissions of works of scientists of the world, and the

results of Erosion and irrigation in the Institute research on

some definition NANA parameters of irrigation technology in

conventional machines, sprinkler machines pulse actions, etc., for

which we offer the following characteristic control to determine

the basic parameters of pulse devices depending on pressure. But

corresponding to the initial pressure pneumatic accumulator p0

and the corresponding atmospheric pressure p and cross -sectional

areas, bringing the pipeline ω2 inlet flow coefficients pneumatic

accumulator μ1 and μ nozzles2, resources pneumatic accumulator t*,

sprinkler apparatus N*, the coefficients that depend on the value of

sprinkler apparatus (d)1 and (d)2, [1,2,3,7].

It should be noted that equation (6) matches the water supply

and water plants, and equation (7) and (8), respectively, the

optimum size of sprinkler devices and agro technical requirements

and quality of rain (the number of sprinklers drops with a diameter

of more than 1.0-1.5 mm in overall flow rain Jet should be less than

10%). Each group of m, q, S, θ correspond definite values x, y, N, l and

system settings h2 n1, W0, D pulse settings of the apparatus. Bearing

in mind that the real system tM1 = t >M2 and sum of hydraulic resistance

to worst according to the terms of the pnevmogidroakkumljatora

filling system Σ ξ = > 1, equation (6) you can submit in the form:

[1,7]

Qi-factor of 2.64 for steel pipes. 10-3/Equation (7,8 and 9)

together with the formula for Ap Ruseckogo represent a closed

system of equations. The below Figure 2 provides a graphical

solution of this system. Knowing the economic radius of action

impulse apparatus and setting from system (= 3-5), the search for a

solution should lead to corresponding with curves in the following

order and1 and4, and7 and10 for s = 3, by and 2 and5 and8 and11 when

c =4 and3 and6 and9 and12 when c =5. Parameters of sprinkler unit with

intermediate values with determined by interpolation. Using the

results obtained previously, define the structural and technological

parameters of pulse apparatus for the same natural-economic

conditions. With the placement of devices on the squares economy

its radius R= 21-35, and c = 3 [1,3]. Using monographs s and the

input values to and (C) pulse parameters are as follows:

(P)1= 450 kPa, P2 = 700 kPa, W0 = 0.19 m3, D= 20 mm.

To address the complex of actions on system reliability is

reliability elements sprinkler systems. Research of reliability

indicators of basic elements of fixed sprinkler system are the

results of theoretical and experimental research, evaluated, tele

control devices noise immunity parameters dispersion, irrigation

norms precipitate individual sprinkling and installed types and

parameters of distributions of operating time to failure of the main

elements of the systems sprinkling [3,4]. In moments the adoption

of tele control device command “select object” in the network of

technological pipelines occur transients. Found that the pressure

p can be set to lower static pressure reconfiguring tele control

devices r/

0 and duration of exposure of the false signal can reach

0.15-1.2 sec. Received the following experimentally confirmed the

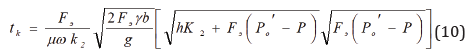

dependence between team processing time signal tk , swing Rod

h effective membrane area (F)e, a cross section of tube connecting

the technological pipeline with working hydraulic factor ω dental

rigidity to the recoil spring2 , specific gravity γ water b and the

acceleration of gravity (g) :

According to the formula (10) evaluated the time reconfiguring

device automated tele control. At instant slide. pressure in the

hydraulic drive to atmospheric pressure, kPa, corresponding

pressure 340 item Chooser requires 0.34 c 1.5 times greater than

the duration of a false signal. (10) allows you to not only assess the

time reconfiguring devices of automated process control systems

tele control channel irrigation, but to appoint him constructive

value parameters in accordance with the requirements of noise

items tele control systems [3]

Start pressure dissipation of impulsive actions self-oscillatory

apparatuses splash leads to dispersion of their volumes Δ splash W

layer and therefore rain m, so how are they related dependencies.

(the number of cycles of performance in a year and its service

area). Testing of pulse (100 picks) and the subsequent processing

of the received data found that distribution of r2 and r1, subject to

the normal law with coefficients of variation of νP2 = 0.04 and νP1 =

0.093. Bearing in mind

A what

the density distribution of m can be represented as:

from constructive impulse imperfections. Obviously, the smaller

the ratio δΔw/Δ W , the machine better.

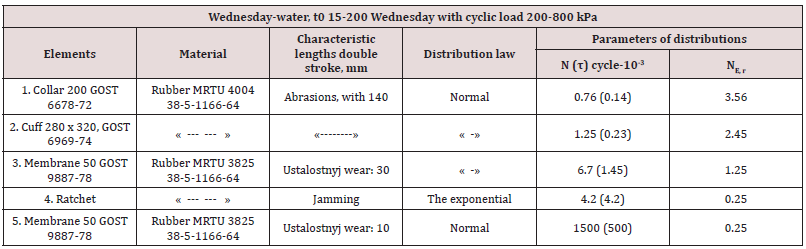

Studies (Table 1) on the definition of the types and distributions

of operating time to failure ( N , σ- coverage and root mean square

deviation) typical sprinkling systems devices, including the most

common elements in hydro automatics: the underground sliding

hydrants (elements 1, 2), devices, systems automated supervisory

control (items 3, 4), yaw (element 5) as well as impulse sprinkler

machines (6.7 items, 8, 9). It is established that the distribution of

time to restore those elements, you can characterize the average

recovery time tin [3,6].

Discussion of research results

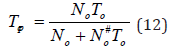

As a result of special research received the following relationship

between the average service life of parts made of rubber or plastic

tWed, the average number of cycles N#

0 a year and experimental aging

value of these materials in the water t0equal to 6.8 years:

In addition to these activities required to address the optimal

level of operational reliability of stationary systems should

develop institutional arrangements. For organizational activities

of particular importance was the implementation of preventive

works and correctly spent time. The timing of prevention is one

of the main problems of preventive maintenance, which is closely

linked to the content of preventive works and the Organization of

their execution [7]. These terms are usually defined in the study the

following objective function:

where, with1,2 respectively, the cost of replacement of parts

when troubleshooting failures and preventive replacements; (M)

(t), N(t)-respectively, the average number of replacements in case

of failure and preventive services for time t.

Scientific conclusions

Expelled us measure perfection is appropriate with a view to

selecting the best design because it is economically summarizing

indicators of maintainability of systems security, persistence, and

sprinkling

Follow on Linkedin : https://www.linkedin.com/company/lupinepublishers

Follow on Twitter : https://twitter.com/lupine_online

No comments:

Post a Comment

Note: only a member of this blog may post a comment.