Lupine Publishers | Journal of Textile and Fashion Designing

Introduction

For high performance and specific applications, fibre reinforced composites mentioned in the first sub-category are more useful and for low-cost general performance and less specific applications, the fibre reinforced composite material in the second sub-category are recommended, while the third sub-category of fibre reinforced materials mentioned above have been still finding its applications in many newer areas like making blades of fan, etc. From different applications point of view, different varieties of composites materials can provide tailor-made products of required properties to a precise specification for specific application. However, different applications need different property aspects.

In aerospace application, stiffness for lowest weight is the dominant requirement for engineering structure, where cost is of little account. For many sports application performance, price is much a secondary consideration. There are, however, many other uses which require equal importance of performance and price.

Price-wise, use of jute fibre, as a natural, renewable low-cost reinforcing fibre, in the composite has obvious advantages with the risk of less water and weather resistant property.

Presently, polyester fibre has become cheaper fibre among other synthetic commodity fibres and therefore use of polyester fibre waste as reinforcing composites may be an alternative economical proposition. The order of tensile modulus values of some typical reinforcing fibres given below reveals that jute, together with other conventional commodity textile fibres, are clearly inferior in performance to metals or newer range of high performance fibres, are clearly inferior in performance to metals or newer range of high performance fibres such as Kevlar, glass, boron, carbon (HT) i.e., high tenacity carbon and carbon (HM) i.e., high modulus carbon fibres.

Increasing order of tensile modulus i.e., Stiffness Value:

Nylon<Cotton<Polyester<Jute<Glass <Aluminium<Kevlar<Carbon (HT)<Carbon (HM) <Boron<Mild steel.Increasing order of Tensile Strength Value

Aluminium<Mild steel<Cotton<Jute<Polyester<Nylon<Carbon (HM)<Carbon (HT)<Glass<Boron<Kevlar.However, the order of stiffness i.e., tensile modulus or tensile strength do not convey the full picture, as because weight and cost are two important factors in many applications. So modulus (a measure of stiffness) per unit weight i.e., specific stiffness and strength per unit weight i.e., specific strength as well as stiffness/ until cost (i.e., cost normalized stiffness) and strength/unit cost (cost normalized strength) are more important parameters to compare. The followings are in the increasing order of the said parameters.

Increasing order of Specific Stiffness (tensile modulus/ unit weight in N/tex)

Nylon <Cotton<Polyester <Jute<Glass<Aluminium< MildSteel<Kev- lar<Boron<Carbon(HT)<Carbon (HM).Increasing order of normalized Stiffness/unit cost

Boron<Nylon<Cotton<Kevlar<Caron (HT)<Carbon (HM)<Polye ster<Glass<Jute<Aluminium<Mild-Steel.Increasing order of specific Strength (Tensile Strength/ unit weight in N/tex)

Aluminium<MildSteel<Cotton<Polyester<Jute<Nylon<Carbon (HM)<Glass<Boron<Carbon (HT)<KevlarIncreasing order of normalized Strength/unit cost

Boron<Aluminium<Carbon(HM)<Carbon(HT)<Kevlar<MildSteel <Cotton <Polyester <Jute <Glass<Nylon.Jute has a specific strength greater than that of aluminium and of mild steel, as well as specific stiffness of jute is greater than those of nylon, cotton and polyester, though is lower than that of the two metals (aluminium and mild steel). Thus, on specific stiffness basis, jute is a favourable reinforcing material. Further, considering the implication of price, and looking into the above shown order of cost normalized strength values of different materials, jute stands out as very effective and favourable reinforcing material. However drawback of jute-based composites being its poor water and weather resistance, its use in interior applications and/or in less humid or dry areas as wood-substitute was thought to be more effective.

Jute based composites restricts its use to modest/high temperature, and humid or corrosive environment. Jute, despite its lower strength than high performance fibres, can lead to composites of high specific strength because of its low density compared to metals and high performance fibres like glass, etc. The possibility of using jute as cheap reinforcing fibre for fabrication of composites has been investigated by authors [1-6]. Unlike man- made monofilament reinforcement, jute fibre displayed greater reinforcing efficiency when embedded in a polyester resin matrix than were predicted from measurement of mechanical properties in individual fibres. This is believed to be due to the co-operative interaction of ultimate cells when surrounded by a matrix resin.

However, little has been studied on the possibilities ofapplication of jute based composites as substitute of wooden or metallic parts in different machinery such as looms etc. Substitution of wood by fibre reinforced composites is gradually being increased under economic and environmental pressure. So, with this background information, it was thought appropriate to study the possibilities of use of jute reinforced polyester resin (JRPR) composite materials for making picking stick in non-automatic silk looms and machine parts of other textile machinery. It was also thought useful to produce some jute polyester fibre hybrid composite in polyester resin matrix for other applications considering the potential multiplicity of applications of tailor-made composites of varying composition and design.

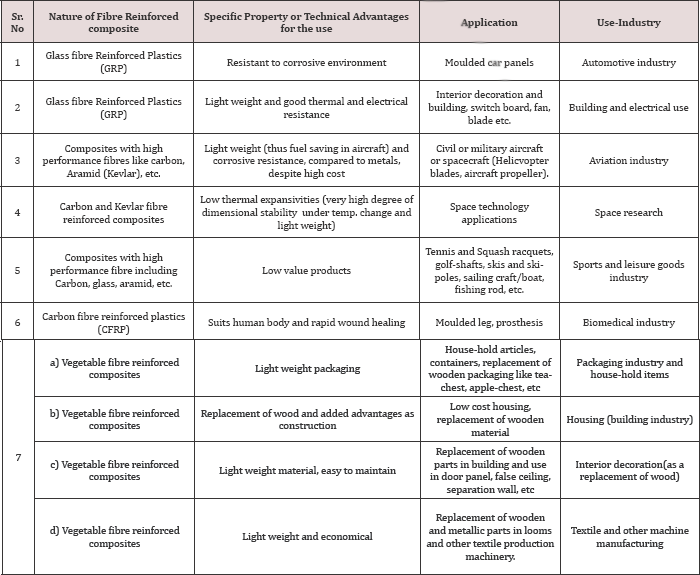

Multiplicity in Applications of Fibre-Reinforced Composites

Table 1: Different Applications of Varied Quality and Type of Fibre Rein forced Composites.

For more Lupine Publishers Open Access Journals Please visit our website:

Follow on Linkedin : https://www.linkedin.com/company/lupinepublishers

Follow on Twitter : https://twitter.com/lupine_online

For more fashion and textile research journal articles Please Click Here:

To Know More About Open Access Publishers Please Click on Lupine Publishers

Follow on Linkedin : https://www.linkedin.com/company/lupinepublishers

Follow on Twitter : https://twitter.com/lupine_online

No comments:

Post a Comment

Note: only a member of this blog may post a comment.