Abstract

Keywords: Artificial Neuronal Network; Regression; Feed-Forward Backpropagation; Mineral Drying

Introduction

Materials and Methods

Description of the Mineral Drying Process

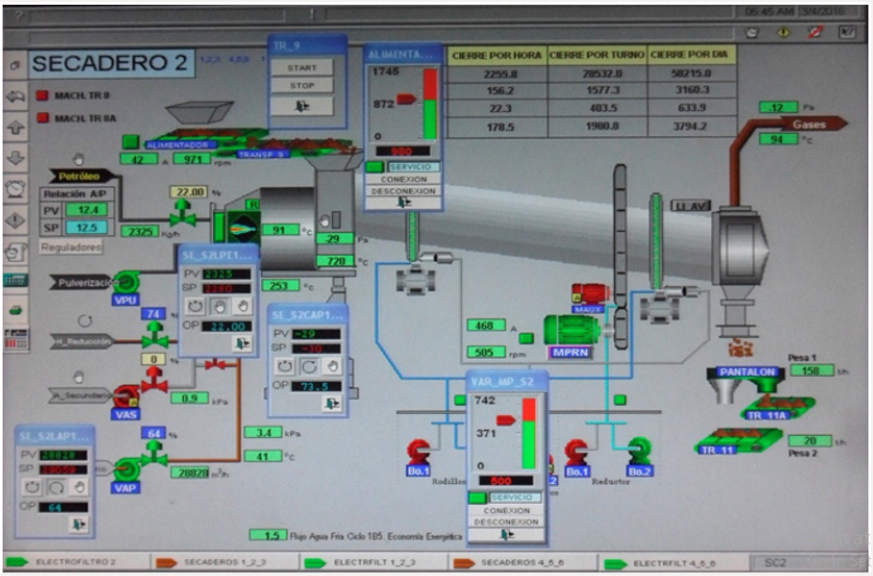

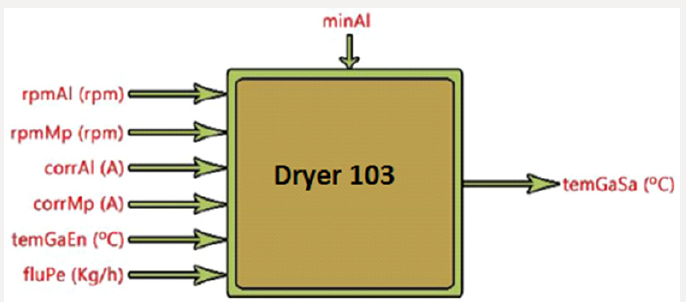

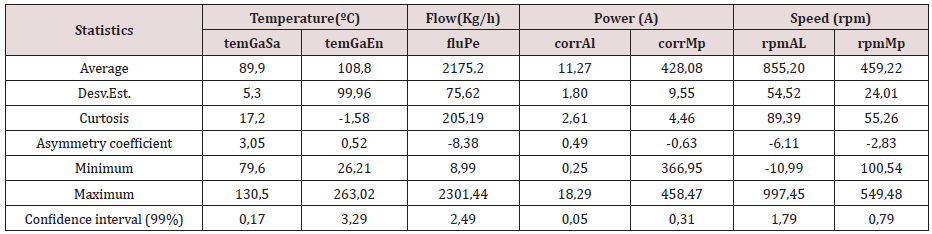

The drying of the ore is carried out in elongated cylinders formed by a combustion chamber where the hot gases that dry the ore are produced, and by the cylinder where the ore will receive the drying process. These drums (Figure 1) have in their interior lifting elements that are responsible for allowing the transfer of heat between the hot gas and the mineral, in addition the dryer drum has a motor system coupled to the body of this which allows it to rotate on its axis. The dryer drum externally rests on two wheels that has two pairs of roller. Internally the dryer is formed near the combustion chamber by guides or baffles welded to the body of the drum that are the ones that direct the mineral towards the outside of the cylindrical part of the drum [5]. The mineral dryer is a complex physical-mathematical modeling object with a large number of input and output parameters which are in a complex interdependence (Figure 2).The Input Parameters in the Process are:

a) rpmAl - Feed motor speed [rpm].

b) rpmMp - Speed of the main motor [rpm].

c) corrAl - Feed motor power [A].

d) corrMp - Power of the main motor [A].

e) temGaEn -Temperature in incoming gases [ºC] (coming from the Reduction Furnaces Plant).

f) fluPe - Oil flow at the burner inlet [kg/h].

The Output Parameter is:

a) temGaSa - Oulet gas temperature [ºC].

In addition to the input and output parameters, it is important to highlight a specific disturbance of this process that influences it, which is: minAl - Mineral fed to the dryer. It is known that there are other parameters that are involved in the drying process of the ore and that in turn influence the temperature of the exhaust gases in the evacuation chamber (granulometry in the entrance mineral, humidity of the entrance mineral, exact amount of mineral fed to the dryer), but due to the process itself, they are not registered. Due to the automation existing in the process, the values of the process parameters are sensed by the instrument corresponding to each of them and the signal is sent to the computer located in the process control office. The data obtained along 1 month of operation, were recorded every 240s and processed with the Stat graphics Plus V 5.1 software.

Artificial Neural Networks

The determination of the type of artificial neural network, the number of layers and the number of neurons in each layer that best characterize the process of ore drying process was carried out through a trial and error process that plays with the number of neurons and the maximum permissible error. Through Matlab’s Toolbox (nnstart), the performance of artificial neural models was evaluated by using the mean square error and the correlation coefficient between the real values and those obtained by the network [6]. The objective was to provide the network with an adequate number of neurons in the hidden layer to learn about the characteristics of the possible relationships between the sample data. Through the trial and error process, it was identified the feedforward back propagation structure that provided better results. The proposed network consists of two layers: a hidden layer and an output layer. The output layer will only have one unit, which will indicate the value of the oulet gas temperature associated with each input vector presented to the network. The hidden layer will have a variable number of neurons.Results and Discussion

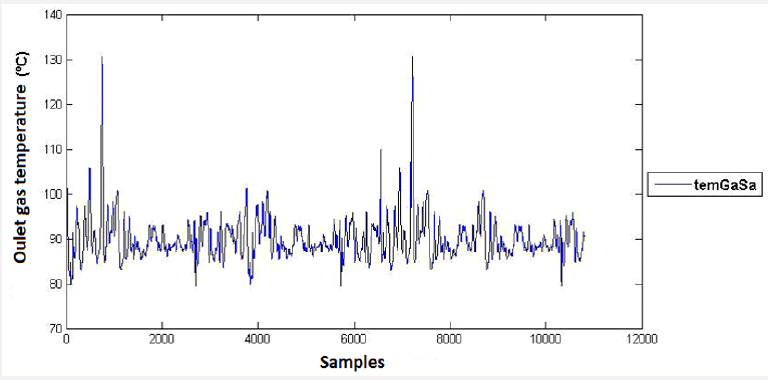

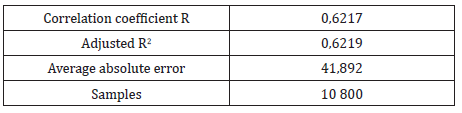

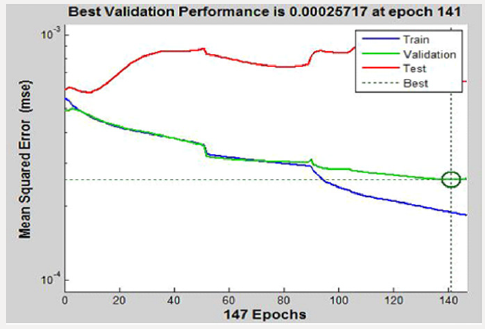

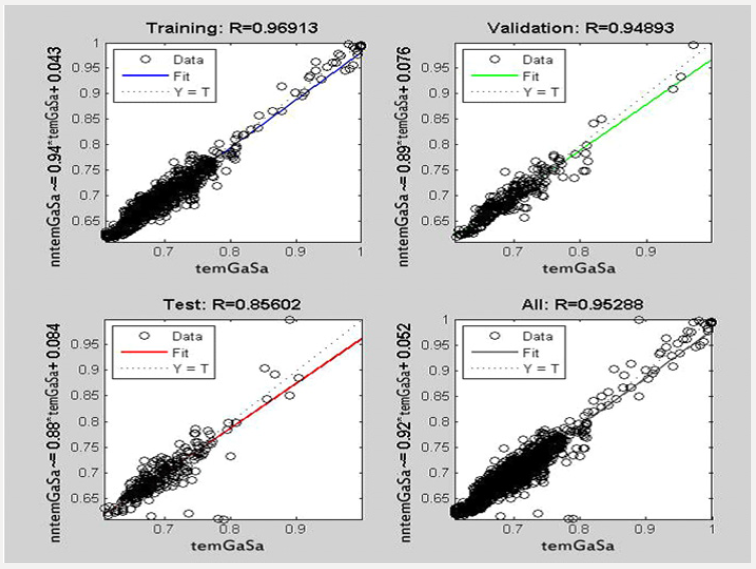

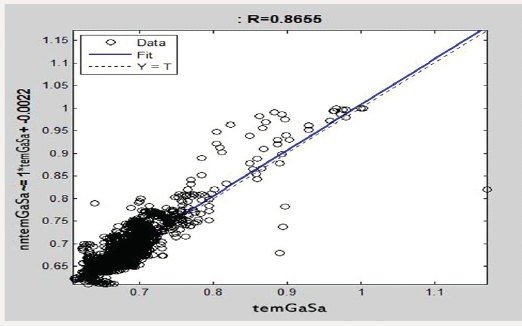

Figure 4 shows the training behavior of the network for the learning process, observing the training, validation and test curves, which converge to the iterations for an error of 0,00026. Figure 5 shows the behavior of the correlation coefficients for the training, validation, testing and adjustment of the artificial neuron network (it is assumed as an artificial neuronal model for the oulet gas temperature in the ore drying process “nntemGaSa” and the real temperature “temGaSa”). Figure 6 shows the generalization of the network with 1767 data not presented during training, where a 0,87correlation coefficient is observed.

Conclusion

For more Lupine Publishers Open Access Journals Please visit our website:

For more automation

engineering Please Click Here: www.lupinepublishers.com/robotics-mechanical-engineering-journal/index.php

To Know More About Open Access Publishers Please Click on Lupine Publishers.

To Know More About Open Access Publishers Please Click on Lupine Publishers.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.