Brass is an important metalloid which is used in construction of

sculptures. It is noticed that sculpture of brass is corroding due

to interaction of pollutants. The pollutants develop chemical and

electrochemical reaction on the surface of base material. Their

concentrations of corrosive pollutants are increased in winter season.

The air quality becomes very poor in winter season. Inside

sculpture different forms of corrosion are observed like galvanic,

pitting, stress, crevice etc. The major components of pollutants are

oxides of carbon, oxides of nitrogen, oxides of sulphur, ammonia, ozone

and particulates. Among these pollutants oxides of sulphur

and ammonia are major corroder of brass. Ammonia is observed moist air

to form ammonium hydroxide. It produces chemical

reaction with brass metal and form complex compounds like [Zn(NH

4)

4](OH)

2, [Zn(NH

4)

4]SO

4, [Zn(NH

4)]CO

3, [Cu(NH

4)

4](OH)

2,

[Cu(NH

4)

4]SO

4, [Cu(NH

4)]CO

3

etc. Oxides of sulphur react with moist air to exhibit sulphurous and

sulphuric acids. They interact

with brass to develop corrosion cell zinc metal and it is oxidized into

Zn2+ ions and these ions are active to humidity and carbon

dioxide to yield Zn(OH)

2.ZnCO

3.2H

2O. Copper is converted into Cu

2+ and it reacts with moist air and carbon dioxide to produce

Cu(OH)

2.Cu(CO

3)2 and these complex compound

detached on the surface of brass metal by rain water. These pollutants

change their

physical, chemical and mechanical properties and they also tarnish their

facial appearance. Brass’ sculpture is affected by uniform

corrosion. This type of corrosion can be control by nanocoating and

electrospray techniques. For this work (6Z)-5,8-dihydrazono-

5,8-dibenzo[a,c][8]annulene and TiO

2 are used as nanocoating and electrospray materials. The corrosion rate of material was

determined by gravimetric and potentiostat technique. The nanocoating and electrospray compounds are formed a composite

layer on surface of base metal. The formation of composite layer is analyzed by thermal parameters like activation energy, heat

of adsorption, free energy, enthalpy and entropy. These thermal parameters were calculated by Arrhenius, Langmuir isotherm

and transition state equations. Thermal parameters results are depicted that both materials are adhered with sculpture through

chemical bonding. The surface coverage area and coating efficiency indicates that nanocoating and electrospray are produced a

protective barrier in ammonia and sulphur dioxide atmosphere.

Keywords:Brass sculpture; Corrosion; Atmospheric pollutants; Nanocoating; Electrospray; Sulphur dioxide; Composite barrier

Introduction

The sculpture of brass comes in contact of contaminated air

thus its deterioration starts for protection various types methods

can be applied [1]. Brass [2] has major components is copper and

zinc. Zn reacts the hot air to produce ZnO which is active in humidity

[3] to convert into Zn(OH)

2. In moist air [4], they form CuO, ZnO,

Cu(OH)

2 and Zn(OH)

2. Both metals are active with sulphur to yield

Cu

2S, CuS and ZnS and these metallic sulphides [5] react with moist

air to give Cu(OH)

2, Zn(OH)

2, CuSO

4 and ZnSO

4. The hydroxides

of these metals interact with CO2 to produce CuCO

3 and ZnCO

3.

Sulphur dioxide [6] is a culprit of brass. It undergoes with Cu(OH)

2

and Zn(OH)

2 to convert into CuSO

4 and ZnSO

4. Moist SO

2 yields

H

2SO3 and H

2SO

4 whereas they create acidic environment [7] for

brass and generate corrosion cell on their surface. It accelerates

disintegration [8] in metal components of sculpture of brass. Brass

is highly sensitive to ambient of ammonia gas [9]. It interacts with

humid atmosphere [10] to NH4OH and it deposits on the surface

brass metal [11] thus it converts into a complex layer of [Cu(NH3)4]

(OH)

2 and [Zn(NH3)4](OH)

2 that layer erosion starts in rain water.

[Cu(NH3)4](OH)

2 and [Zn(NH3)4](OH)

2 complex compounds [12]

come in contact of H

2SO

4 environment to produce [Cu(NH3)4]SO

4

and [Zn(NH3)4]SO

4 that complex layer is eroded in rain water. In

acidic medium brass outer face has developed CuSO

4 and ZnSO

4 when

dust particulates [13] are deposited on their surface which contains

Fe to remove Cu and Zn from outer surface. Dust particulates are

possessed oxides of alkali metal in presence of moisture, it produces

NaOH or KOH [14] that is create hostile environment for Zn and it

forms complex compound [15] Na

2[Zn(OH)4]or Na[Zn(OH)

3.H

2O]

or Na[Zn(OH)

3.(H

2O)

3]. The oxides of NO2 reacts with moist air

to give HNO3 that acid produces chemical reaction with Cu and it

converted into Cu(NO3)2. Some organic acids [16] available in air

like acetic acid which develop corrosive environment for Cu and Zn

which converts Cu into Cu

2(CH

3COO)4.H

2O and Zn into (CH

3COO)

6.

Zn4O complex compounds [17]. They are eroded by rain water

on the surface of brass. Organic compounds [18] like amnio and

sulpur increased day by day in atmosphere. They develop hostile

environment for brass and corroding it. Corrosive pollutants [19]

concentrations like oxides of carbon, oxides of nitrogen, oxides of

sulphur, hydride of sulphur and nitrogen, ozone and particulates

are enhanced due to industrials wastes, effluents, flues and other

factors are like burning of coals, woods and cow dung cakes.

Harmful pollutants [20] come into atmosphere through agricultural

wastes, human wastes, pharmaceutical wastes, household wastes,

food wastes and decomposition of living things. Various types of

transports like road, water and air are evolving CO, NO2 and SO

2

gases which produce acidic environments for brass. Several types

of techniques are used to control the corrosion of brass like metallic

coating; polymeric coating, paint coating, organic and inorganic

coating of materials but these didn’t give satisfactory results in

corrosive medium. Some organic and inorganic inhibitors are

applied to protect the corrosion of materials in acidic but they

provide good results. Hot dipping, electroplating and galvanization

techniques is used as protective tools for brass corrosion in acidic

medium but these methods don’t shave base metals. In this work it

is to mitigate corrosion of brass corrosion by nanocoating and filler

techniques. These materials form composite barrier on the surface

base metal and blocked porosities and stop diffusion or osmosis

process of pollutants.

Experimental

Brass coupons 15sqcm were taken for experimental analysis.

Samples surface were rubbed with emery paper, rinsed with

acetone, dry them and kept into desiccators. Sample kept 20meter

height of roof in open sky and it observed that colour of brass can

be changed. Corrosion rate was determined in winter season by

weight loss method. The concentration of SO

2 in November 75ppm,

December 90ppm, January 105ppm and February 120ppm and

temperatures recorded in this period were 298K, 294K, 291K

and 295K. Synthesis organic compound (6Z)-5,8-dihydrazono-

5,8-dibenzo[a,c][8]annulene used as nanocoating and TiO

2 as

filler and corrosion of brass metal calculated in above mentioned

concentrations and temperatures in winter season. Both

compounds formed a composite barrier on surface of base metal

(Figures 1-4). Surface adsorption phenomenon studied by thermal

parameters like activation energy, heat of adsorption, free energy,

enthalpy and entropy.Potentiostat/Galvanostat model EG&G used

for corrosion potential, corrosion current and corrosion current

density. Brass sample put between H

2|Pt electrode as auxiliary

electrode and Hg

2Cl

2|HgCl

2 electrode reference electrode.

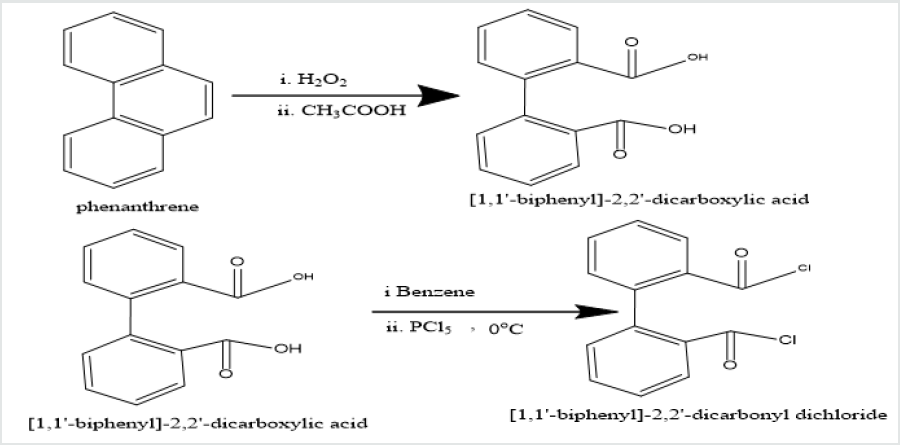

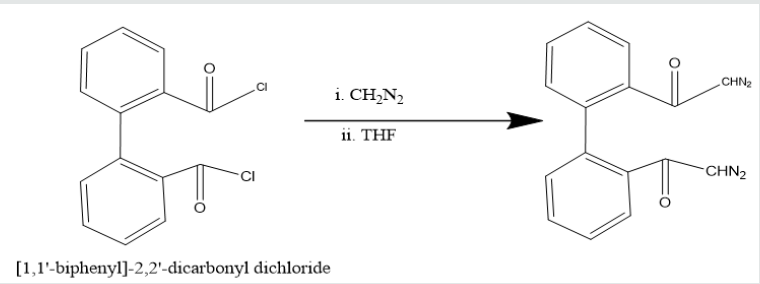

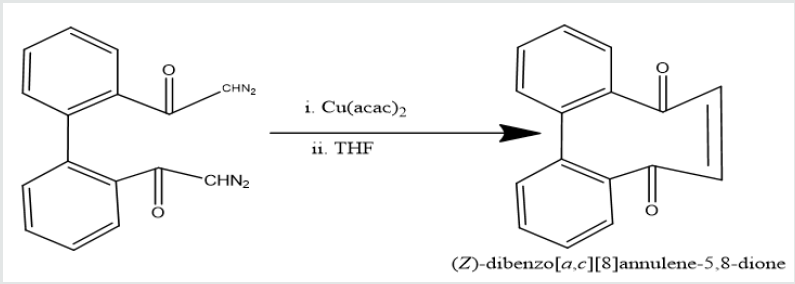

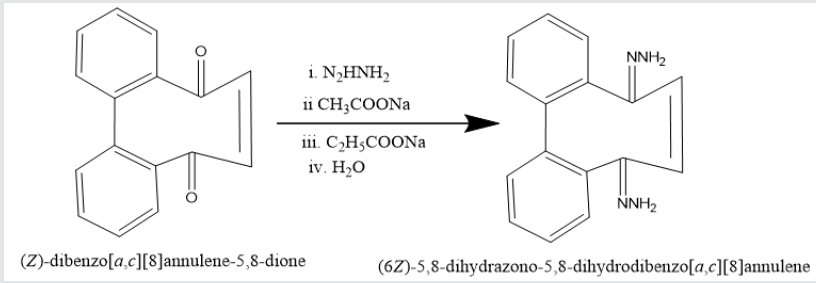

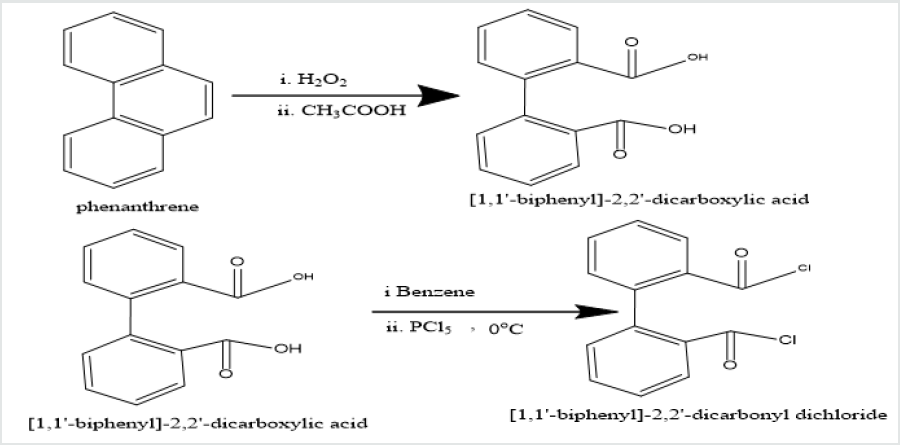

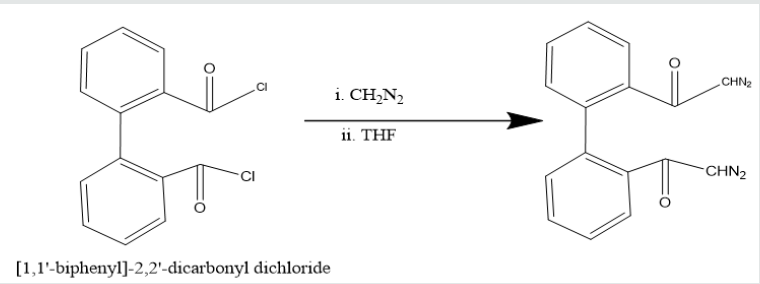

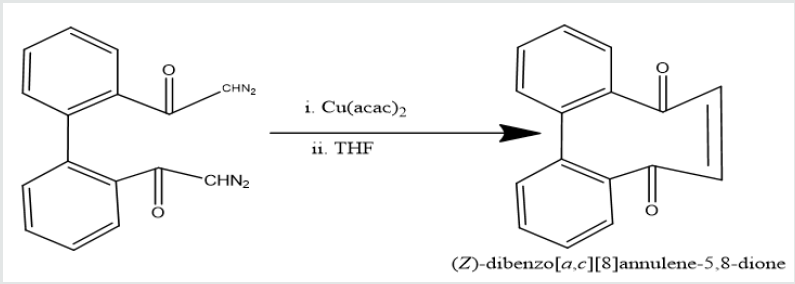

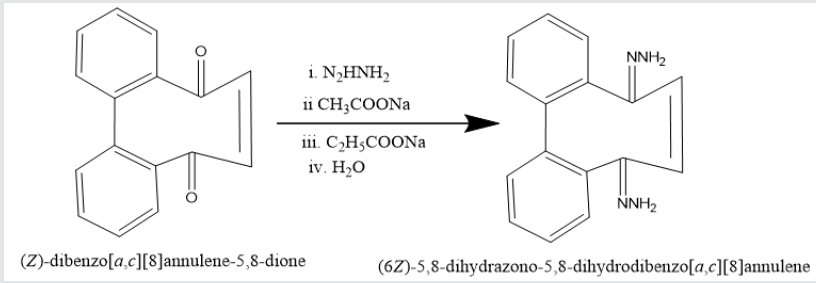

Figure 1: .

Figure 2:

Figure 3:

Figure 4:

Synthesis of (6Z)-5,8-dihydrazono-5,8-dibenzo[a,c][8]

annulene

Phenatharene was oxidized into [1,1’-biphenyl]-2,2’-

dicarboxylic acid by the use of H

2O2 in presence of CH

3COOH. When

[1,1’-biphenyl]-2,2’-dicarboxylic acid was treated in PCl

5 in benzene

solution at 0 oC temperature, [1,1’-biphenyi]-2,2’-dicarbonyl

chloride was obtained. It reacted with diazomethane to produce

yield [1,1’-biphenyl]-2,2’-dicarboxodiazomethan which heated

Cu(acac)

2 in presence THF to yield (Z)-dibenzo[a,c][8]annulene-

5,8-dione. It was used with hydrazine hydrate in ethyl alcohol to

give (6Z)-5,8-dihydrazone-5,8-dihydrodibenzo[a,c][8]annulene.

Results and Discussion

Brass metal was exposed in moist SO

2 environment in 75ppm,

90ppm, 105ppm and 120ppm concentrations and 298 0K, 294 0K,

291 0K and 295 0K temperatures. The corrosion rate of brass metal

was determined in winter season without coating and with coating

(6Z)-5,8-dihydrazone-5,8-dihydrodibenzo[a,c][8]annulene and

TiO

2 electrospray of by weight loss formula K= 534 W/DAT (where

W is weight loss, D is density and T is time) and their values were

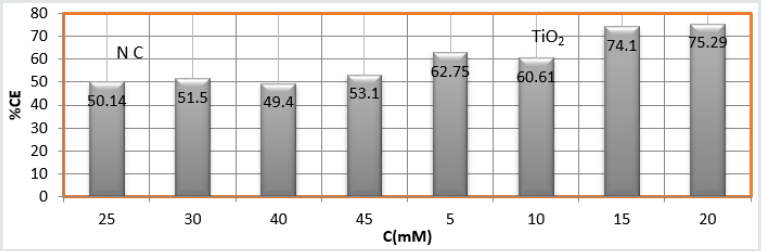

mentioned in (Table 1)

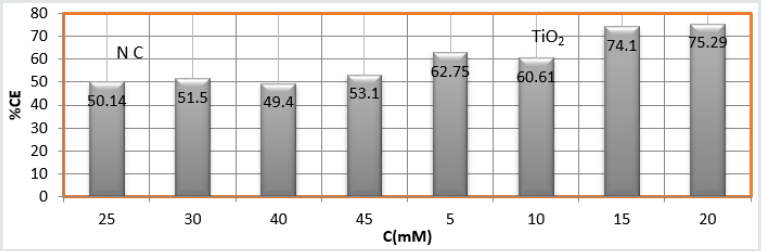

Table 1:Corrosion of Brass Sculpture in Winter Season in SO

2 medium.

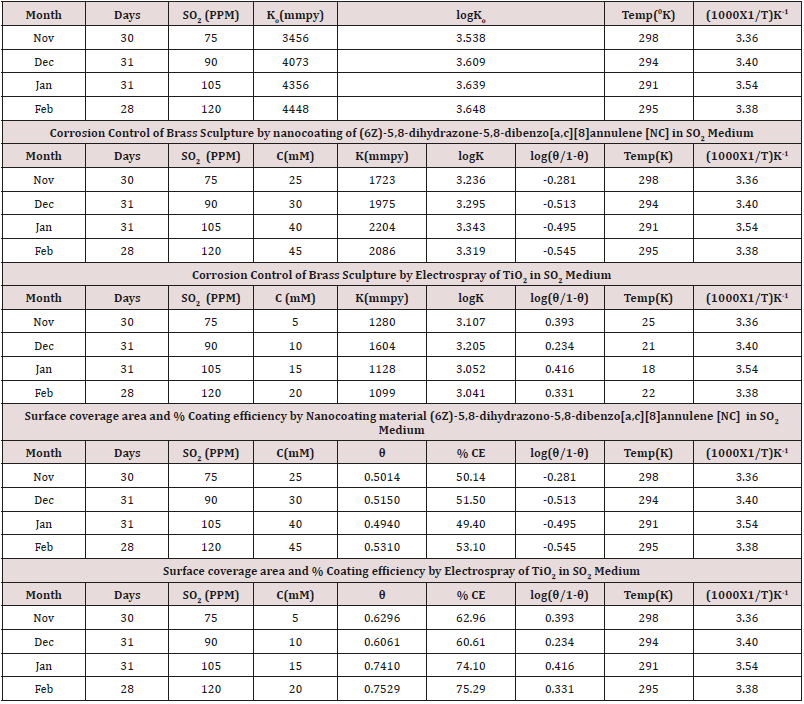

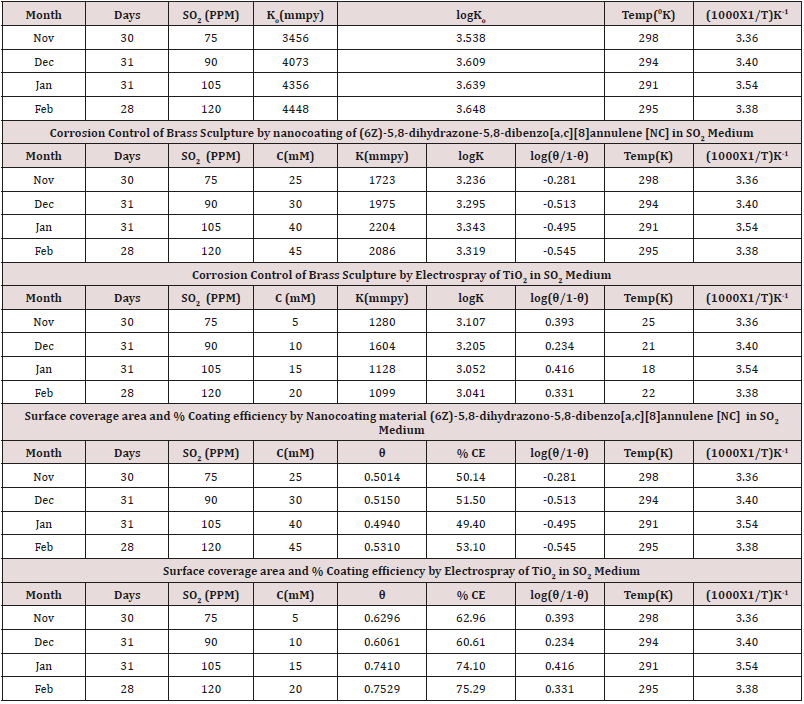

The corrosion rate of brass metal was recorded in the months

of November, December, January and February, the results (Table

1) was shown that corrosion rate of metal increased in January to

February but theses values were reduced with coating and filler

materials like (6Z)-5,8-dihydrazone-5,8-dihydrodibenzo[a,c][8]

annulene and TiO

2. It was clearly noticed in (Figure 5) K versus

Month. Brass metal kept into 75ppm, 90ppm, 105ppm and 120ppm

of SO

2 medium in month of Nov, Dec, Jan and Feb without coating.

It was coated with 25mM, 30mM, 40mM and 45mM concentrations

of (6Z)-5,8-dihydrazone-5,8-dibenzo[a,c][8]annulene, and again

kept into same concentrations of SO

2. After coating of (6Z)-5,

8-dihydrazone-5,8-dibenzo[a,c][8]annulene electrospray coating

of TiO

2 used at 5mM, 10mM, 15mm and 20mM concentrations and

same concentrations SO

2 Nov to Feb. The corrosion rates of in these

three cases were written in (Table 1). These results were shown

that corrosion rates without coating increased, it values decreased

coating with (6Z)-5, 8-dihydrazone-5,8-dibenzo[a,c][8]annulene

but their values more reduced with TiO

2 electrospray. These trends

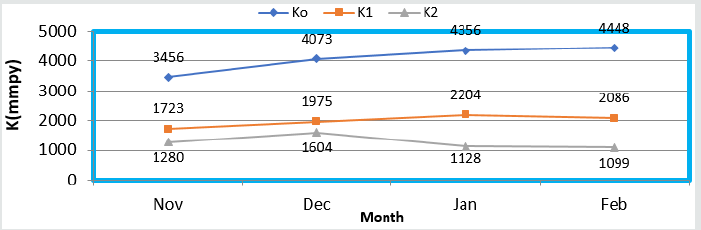

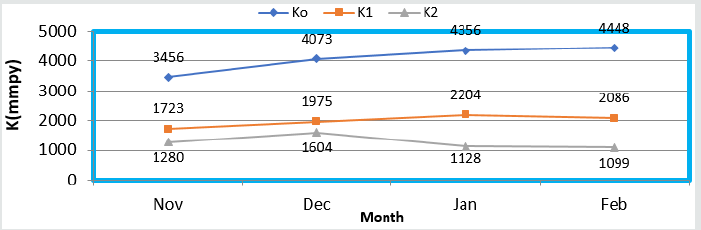

were shown in (Figure 6) which plotted K versus C. The corrosion

rates of brass metal at different temperatures 298 0K, 294 0K, 291

0K and 295 0K without and with coating were recorded in (Table

1). The addition of nanocoating and electrospray were reduced the

corrosion rates as temperatures variation, it noticed in K versus T

in (Figure 7).

Figure 5: K(mmpy) Vs Months for brass metals.

Figure 6: KVs T nanocoating and electrospray.

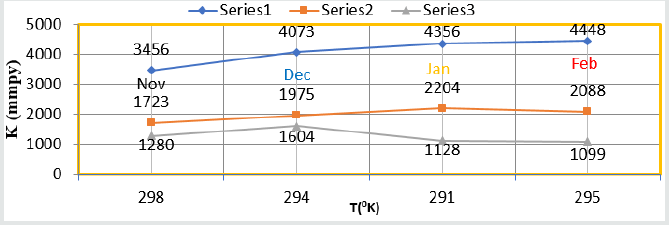

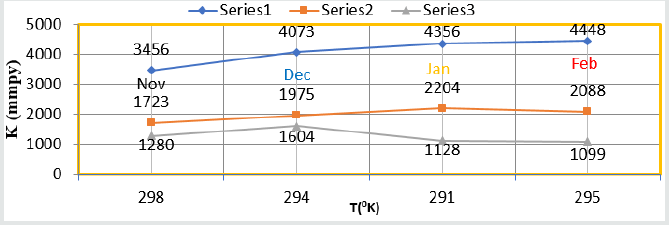

Figure 7: %CE Vs C(mM) nanocoating and electrospray.

Figure 8: %CE Vs T for nanocoating and electrospray.

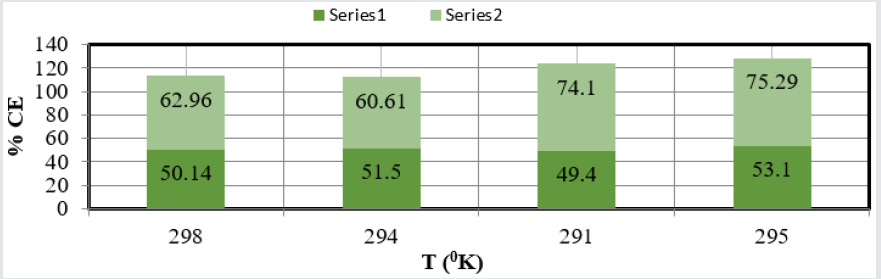

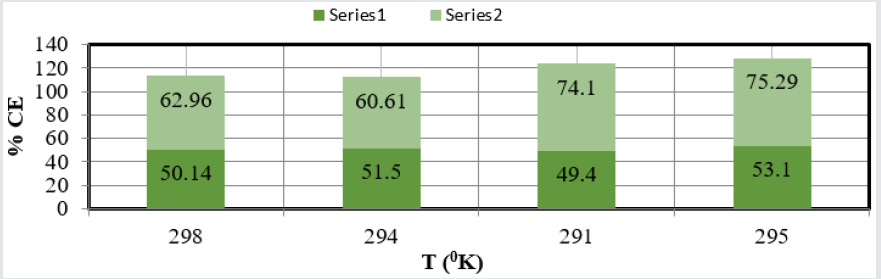

(Figure 8) plot between %C (percentage coating efficiency)

versus C (concentrations in mM) indicated that nanocoating

compound (6Z)-5, 8-dihydrazone-5,8-dibenzo[a,c][8]annulene

increased coating efficiency but TiO

2 electrospray produced more

coating efficiency with respect of nanocoating compound. The

values of % coating efficiency were calculated by formula %CE =

(1-K/Ko) X100 (where Ko is corrosion rate without coating and K is

corrosion rate with coating) and their values were given (Table 1).

(Figure 9) show plot between %C (percentage coating efficiency)

versus T (temperature in K). This figure indicated that percentage

coating efficiency enhanced as temperatures varies in Nov to Feb

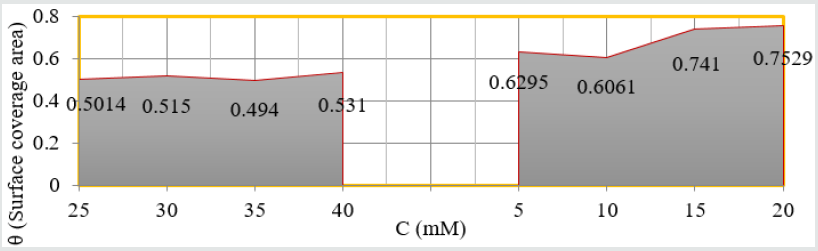

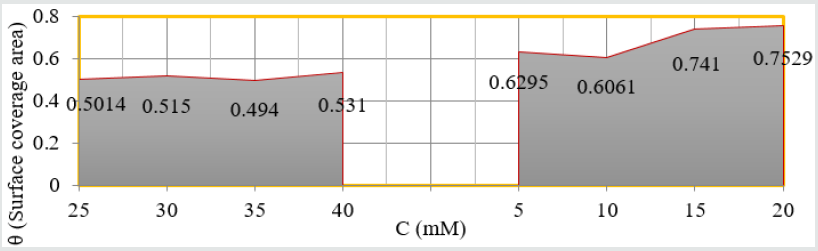

months and their values were recorded in (Table 1). Figure 6

plotted between θ (surface coverage area) versus C (concentration

in mM) and covered areas were produced by (6Z)-5, 8-dihydrazone-

5,8-dibenzo[a,c][8]annulene and TiO

2 were mentioned in (Table 1).

The results were shown that nanocoating compound occupied less

surface areas with respect of electrospray. The surface coverage

area developed by nanocoating and electrospray compound was

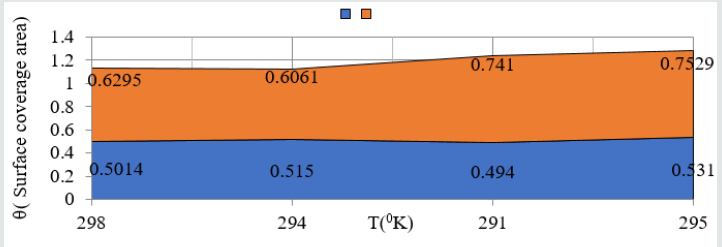

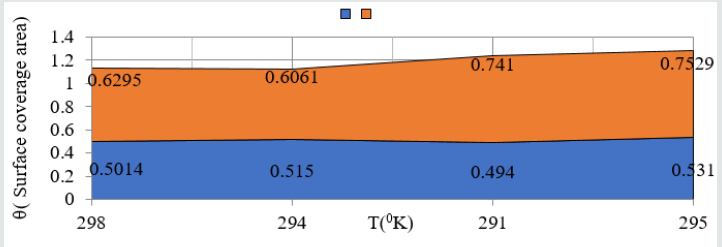

calculated by formula θ = (1- K/Ko). (Figure 10) plotted between

θ (surface coverage area) versus T (temperature) noticed that

temperatures were varies from Nov to Dec but surface coverage

area and electrospray values were increased and their values were

written in (Table 1).

Figure 9: Vs C nanocoating and electrospray.

Figure 10: θ Vs T for nanocoating and electrospray.

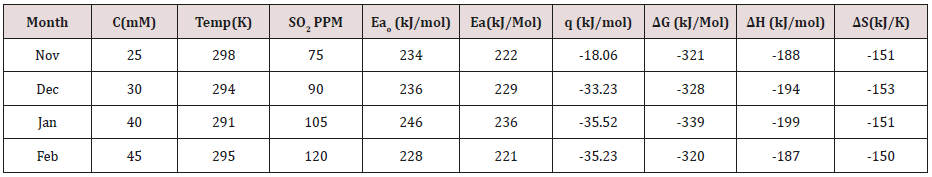

Table 2:Thermal Parameters of Brass Sculpture in Winter Season by Nanocoating of (6Z)-5,8-dihydrazono-5,8-dibenzo[a,c][8]

annulene [NC] in SO

2 Medium.

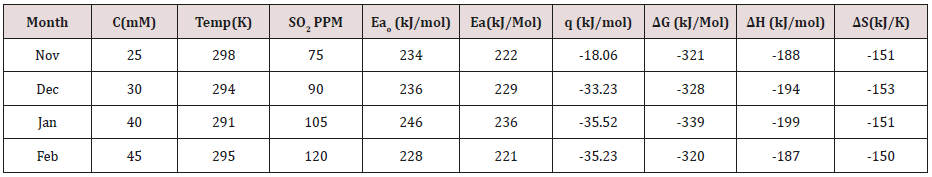

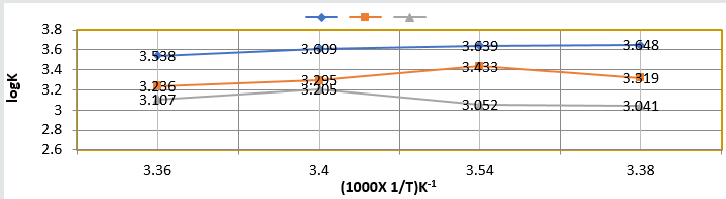

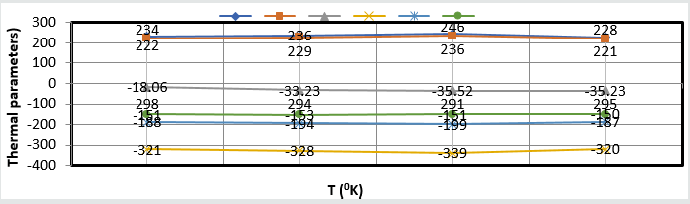

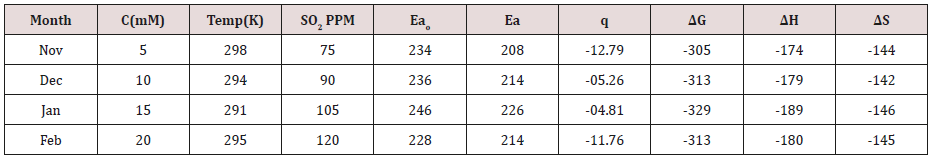

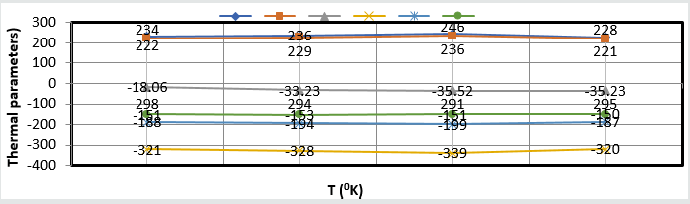

Composite surface formation was studied by Arrhenius

equation, Langmuir isotherm and others thermal parameters

like activation energy, heat of adsorption, free energy, enthalpy

and entropy and their values were recorded in (Table 2). (Table

2) Thermal Parameters of Brass Sculpture in Winter Season by

Nanocoating of (6Z)-5,8-dihydrazono-5,8-dibenzo[a,c][8]annulene

[NC] in SO

2 Medium. Activation energy of without coating, with

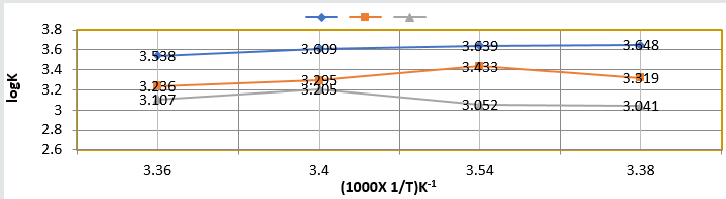

coating and electrospray coating were determined by Arrhenius

equation d(logK)/dT = A – Ea/2.303RT and their values were

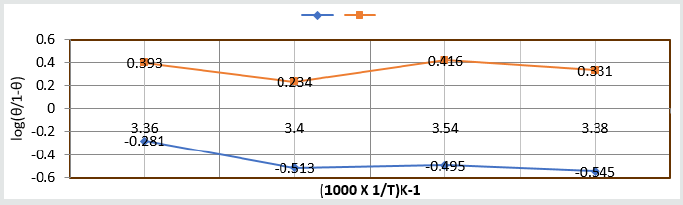

recorded in (Table 2). The plot between logK versus 1/T was found

to be straight line as shown in (Figure 11). The plot between log

K and 1/T found to be straight line. It observed that activation

before coating activation energy high but decreased after coating.

These trends indicated that nanocoating compound adhered on

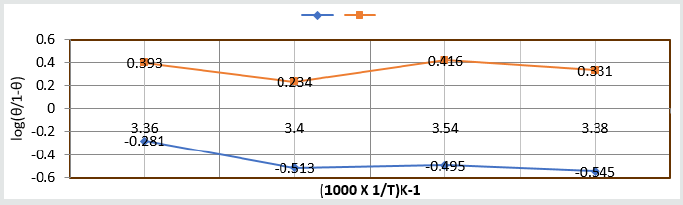

the surface of base metal. Heat of adsorption was calculated by

Langmuir isotherm log(θ/1-θ) = log(AC) – q/2.303R T and their

values were mentioned in (Table 2). Its values were found to

negative, it indicated nanocoating compound formed chemical

bond with base metal. (Figure 12) log(θ/1-θ) versus 1/T proved

results of heat of adsorption.Free energy values of nancoating

compound were determined by formula ΔG = -2.303 RT log(33.3K)

and their values were recorded in (Table 2). Their values found

to be negative; it noticed that nanocoating compound adhered on

the surface of base metal by chemical bond. Enthalpy and entropy

values of nanocoating and electrospray compounds were calculated

by transition state equation K=k T/N h e

ΔS/R e

-ΔE/RT and their values

were mentioned in (Table 2). These values were found to be negative

which indicated these compounds adhered on the surface of metals.

All thermal parameters versus T (temperature) plotted in (Figure

13) which indicated composite barrier formed on surface of base

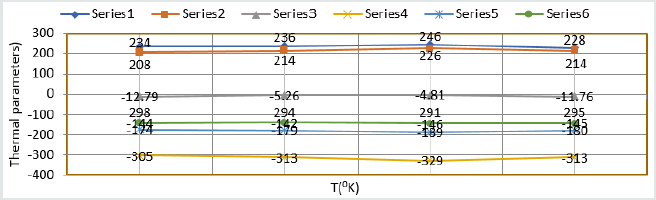

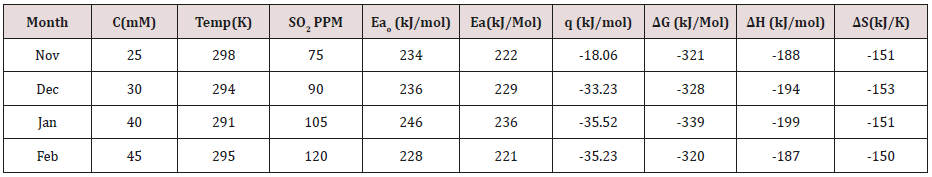

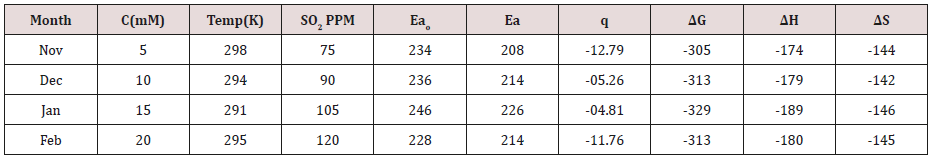

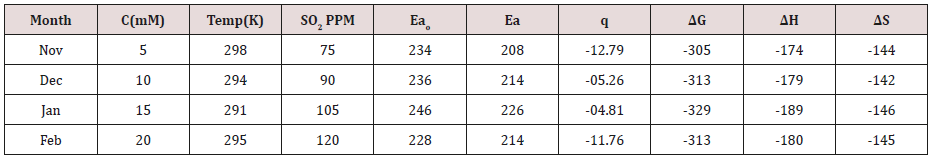

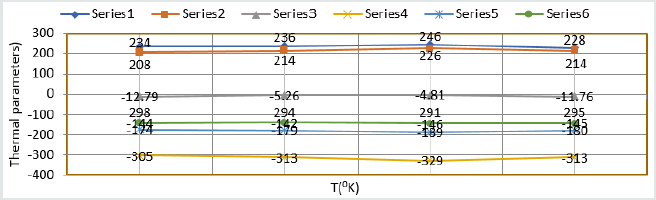

metal. Thermal parameters Values of TiO

2 eleectrospray activation

energy, heat of adsorption, free energy, enthalpy and entropy were

written in (Table 3) and their plot against T (temperature) in (Figure

14). (Table 3) results indicated electrospray compound formed

chemical bond with nanocoating compound. (Table 3) Thermal

Parameters of Brass Sculpture in Winter Season by Electrospray of

TiO

2 in SO

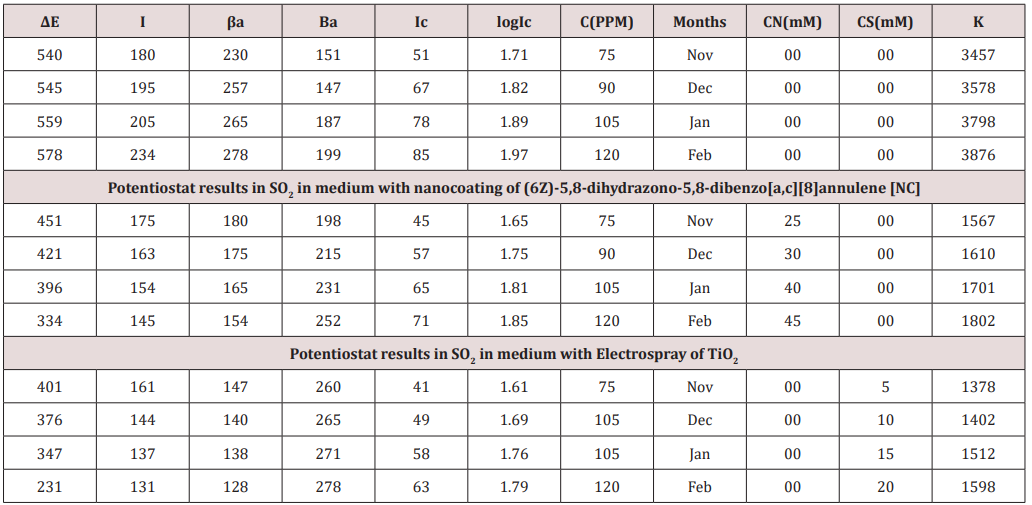

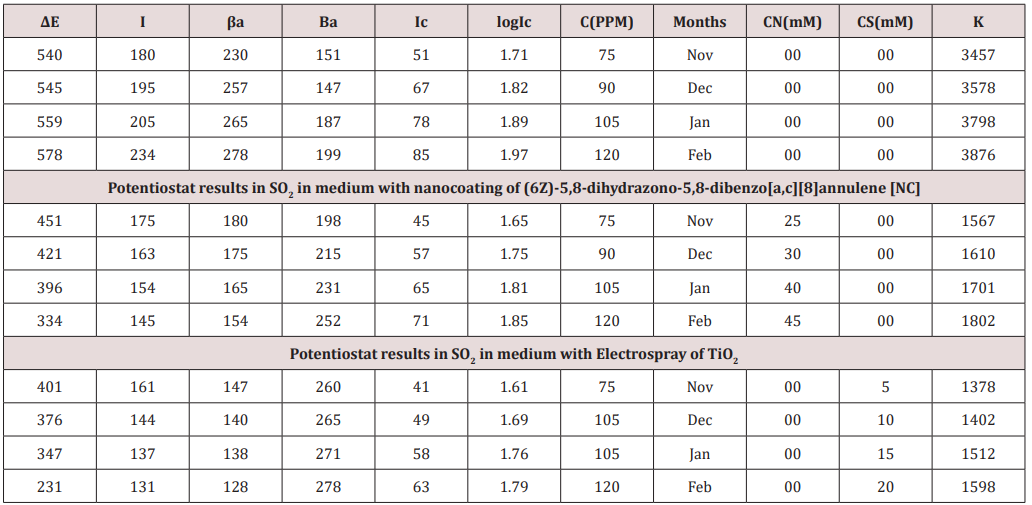

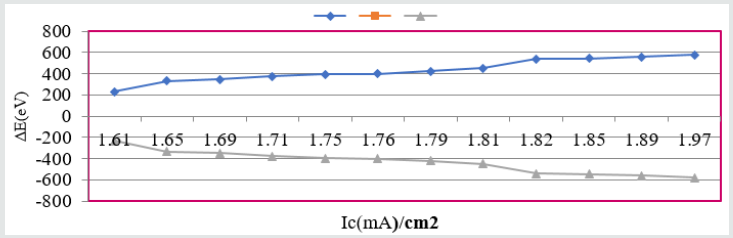

2 Medium Potentiostat results were determined with help

of equation I = βa βc/2.3 (βa+βc) Ic and corrosion rate K=0.128

X Ic X( E/d) ( Ic is corrosion current, equivalent weight and d is

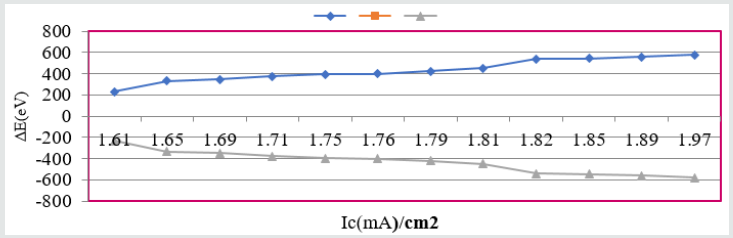

density) and their values were written in (Table 4). (Figure 15) was

plotted ΔE(corrosion potential versus I(corrosion current density).

The results of (Table 4) observed that without coating corrosion

potential high but with coating nanocoating and electrospray

reduced corrosion potential. (Table 4) Potentiostat results in SO

2 in

meduim with nanocoating and electrospray.

Figure 11: logK Vs 1/T nanocoating and electrospray.

Figure 12: log(θ/1-θ) Vs 1/T nanocoating and electrospray.

Figure 13: Thermal parameters Vs T for nanocoating and electrospray.

Figure 14: Thermal parameters Vs T nanocoating and electrospray.

Table 3:Thermal Parameters of Brass Sculpture in Winter Season by Electrospray of TiO

2 in SO

2 Medium.

Table 4:Potentiostat results in SO

2 in meduim with nanocoating and electrospray.

Figure 15: ΔE Vs Ic(mA) for nanocoating and electrospray.

Conclusion

It observed that winter season SO

2 concentration increased.

In this season humidity level found to more so it oxidized sulphur

dioxide into sulphuric acid and created hostile environment for

brass sculpture. It corroded zinc into zinc sulphate in longer period

it produced leaching corrosion. Such types of corrosion controlled

by the use of nanocoating of (6Z)-5,8-dihydrazono-5,8-dibenzo[a,c]

[8]annulene and TiO

2 electrospray. The results of activation energy,

heat of adsorption, free energy, enthalpy and entropy values

indicated that nanocoating compound adhered with chemical

bonding. Thermal parameters results of electrospray confirmed

that TiO

2 bonded with (6Z)-5,8-dihydrazono-5,8-dibenzo[a,c][8]

annulene chemical bonding. Both compound created composite

barrier on the surface of base metal which produced anticorrosive

barrier. The nanocoating compound developed lot of porosities

during coating. These porosities blocked by electrospray and it

increased coating efficiency and surface coverage area.

For more

Lupine Publishers Open Access Journals Please visit our website:

https://lupinepublishersgroup.com/

For more

Material science journal articles Please Click Here:

https://lupinepublishers.com/material-science-journal/

To Know More About

Open Access Journal Please Click on

Lupine Publishers

No comments:

Post a Comment

Note: only a member of this blog may post a comment.