Journal of Nanomedicine | Lupine Publishers

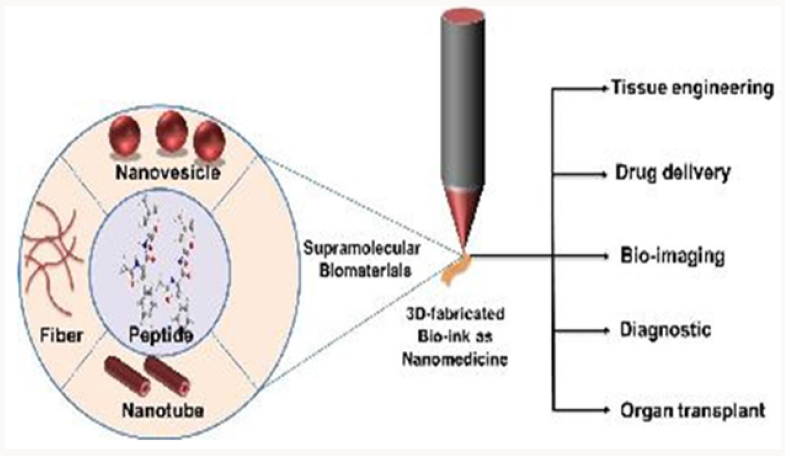

In the current era of research and development, nanotechnology and

additive manufacturing play a key role in the industry as

well as in the healthcare applications. In order to explore medicinal

applications, researchers focus on the design and synthesis

of biocompatible nanoparticles and nanomaterials. Molecular

self-assembly is a powerful approach for the fabrication of

supramolecular functional materials. Self-assembly offers the

integration of nanotechnology with the additive manufacturing for

the fabrication of three dimensional (3D) printed objects. The

cross-linked peptide hydrogels are gaining attention as potential bioink

for the 3D bio-fabrication. The current article focuses on the scope of

the printable peptide containing hydrogels as bio-ink in

the fields of nanomedicine, drug delivery and tissue engineering.

Introduction

Design and the development of smart nanostructures that can

diagnose and simultaneously cure the health problems are the

main goals of the nanomedicine. Self-assembling bio-compatible

functional nanomaterials and their therapeutic activity under

biological environment are the key steps in order to develop

effective nanomedicine. Among various approaches to fabricate

nanostructures, self-assembly offers to fabricate supramolecular

functional nanostructures from their individual building blocks.

Self-assembly process involves through bottom-up approach to

construct supramolecular nanostructures. The nanostructures

including nanofibers, nanovesicles and micelles are formed through

intra- and intermolecular covalent and non-covalent interactions.

Self-assembles nanostructures formed by bioactive materials can

be integrated with additive manufacturing for developing effective

nanomedicine. The layer-by-layer bio-fabrication methods are

introduced in healthcare due to their applications in 3D drug

delivery systems, matured tissue cultures and in-vitro organ

fabrications [1]. Fabrication of patient-specific therapeutic system

facilitates more personalized and beneficial medicinal results. 3D

printing allows low cost and rapid printing of biomaterials that are

composed of drug molecules as well as embedded living cells [2].

The application of printing technologies for nanomedicine requires

the development of suitable materials, which endure not only the

process itself but also help to keep the biological entities stable. 3D

bio-fabrication of nanomaterials is a favourable strategy over direct

3D fabrication at nanoscale resolutions (Figure 1). Running parallel

to nanomedicine and 3D printing technology, various types of

selfassembled

printable materials have been developed by researchers

for medicinal applications. Self-assembled high water containing

nanostructures and extra-cellular native environment mimicking

hydrogels are promising candidates for medicinal applications such

as drug delivery as well as tissue engineering. The development of

nanomedicine bio-fabrication has been less explored due to lack

of suitable bio-inks. A number of hydrogels have been introduced

by worldwide researchers using various natural and synthetic

molecules. Among them, self-assembling printable peptide

containing hydrogels are the promising biocompatible material

for healthcare applications. In order to avoid the premature

collapse of the printed structure, suitable bio-inks need to be

developed carefully. An ideal peptide bio-ink should compose

of supramolecular nanostructure with mechanical rigidity and

shape fidelity. Peptides have the ability to adopt specific structures

which can easily tune by amino acid sequences with tunable

physical and chemical properties. Peptides self-assembled through

various covalent and non-covalent interactions such as hydrogen

bonding, van der Waal forces to construct different nanostructures

including nanofibers, micelles and nanotubular structures. The

peptide nanostructures with high bioactivity provide controlled,

biomimetic environment for cells in regenerative medicine and

drug trapping sites for site-selective drug delivery.

Figure 1: Schematic representation of nanomedicine fabricated by integrating peptide self-assembly with 3D- bio-fabrication.

Printable peptides are promising candidates for regenerative

nanomedicines. Recently, Das reported injectable nanofibrous

self-assembled of Amoc (9-anthracenemethoxycarbonyl)-

capped dipeptide hydrogels. These nanofibrous hydrogels show

antibacterial property and promote cell proliferation of human

white blood cells [3]. The acylated peptide containing two to five

hydrophobic amino acids with polar C-terminal residue selfassembles

in 3D nanofibrous structure [4]. The reported peptides

undergo a remarkable structural transition under the influence of

salt and peptide concentrations in order to increase the stiffness of

hydrogels. These injectable nanofibrous peptide hydrogels further

encapsulate human umbilical vein endothelial cells to stimulate

blood vessel development. Incorporation of active biomolecules

such as DNA, RNA with the peptide is also an important strategy

to develop printable peptide-based regenerative nanomedicine.

A polypeptide - DNA conjugate forms in situ biocompatible

hydrogel bio-ink [5]. The resultant properties of polypeptide and

DNA components result in the hydrogel networks suitable for

viable and functional living cells under physiological conditions.

Mimicking in vivo environment by layer by layer neuronal cells in

three-dimensional models is difficult during in vitro brain model

development. The brain is an enormously complex organ, which

is structured into various regions of layered tissue. Lozano et al.

developed bio-ink by cross linking of RGD peptide with gellan

gum [6]. The resultant polypeptide polymer hydrogel shows

cross linked porous nanostructures which enable to encapsulate

and provide the supportive environment for primary cortical

neurons. Neural network formation in cell supportive matrix offers

the opportunity to provide prototype brain-like structures for

healthcare applications like understanding of brain injuries and

neurodegenerative diseases.

Conclusion

Sophisticated targeted drug delivery and regenerative

therapeutics have gained increasing attention during recent years.

In comparison with conventional drug delivery, 3D bio-fabrication

allows manufacturing of patient specific-drug delivery systems.

Above mentioned examples show the potential of printable peptidebased

hydrogel networks, which can resolve tissue engineering and

regenerative therapeutics problems. Few examples have shown

the printed 3D networks worth for antibacterial and microbial

activity. Development of new peptide-based materials and their

implementation in printable nanomedicine is the key challenges

to become the mainstream technology. 3D printed biomaterials

need to upgrade in order to achieve four-dimensional printing in

healthcare applications.

For

more

Lupine Publishers Open

Access Journals Please visit our website

https://lupinepublishersgroup.com/

For more

Journal of Nanomedicine articles Please Click Here:

https://lupinepublishers.com/nano-science-nano-technology-journal/

To Know more

Open Access Publishers Click on

Lupine Publishers

No comments:

Post a Comment

Note: only a member of this blog may post a comment.